Ceramaret Acquires XJet Ceramic AM System for Precision Manufacturing

Ceramaret is installing Xjet’s Carmel 1400C solution in its Swiss facility.

Swiss-based technical ceramic manufacturer Ceramaret has acquired an XJet Carmel 1400C additive manufacturing (AM) system. The investment followed a benchmarking process which resulted in the company determining that XJet’s NanoParticle Jetting process could produce parts the team had previously deemed not possible.

“XJet technology will provide us with new capabilities, new geometries we can offer our customers, whilst also delivering exceptional time-to-market. Taking 72 hours from a new file to a finished part, it’s an extremely fast process,” says Senad Hasanovic, Ceramaret vice president of Innovation. “However, it was the quality and global cost-per-part that really impressed me, demonstrating that this was an industrially competitive solution.”

The Ceramaret team is experienced with the whole ceramic production process, from design and prototyping to the mass production of high-precision advanced ceramic parts, as it regularly benchmarks technologies from across the industry.

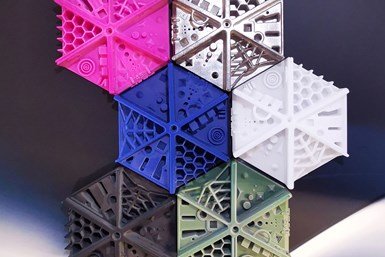

“We couldn’t ignore XJet’s remarkable capabilities after that process. The applications XJet will open up for Ceramaret are remarkable,” Hasanovic adds. “We saw parts that are beyond the reach of any other production method. In particular, there were parts with internal shapes or channels down to 300 microns in diameter and near 300 mm long, which either cannot be produced in a single piece or cannot be produced in bulk with our existing techniques.”

Since the benchmarking process, Ceramaret has collaborated with XJet to test 30 distinct products with around 300-400 manufactured parts. Hasanovic and his team also visited Xjet’s Additive Manufacturing Center in Rehovot, Israel, witnessing the entire production process firsthand.

“We scrutinized each of the test parts, polishing them and checking their structural integrity, their porosity, functionality and more,” Hasanovic says. “These investigations convinced us that the parts would meet the needs of our customers and add value to the manufacturing services we offer.”

Andy Middleton, XJet vice president Europe, notes that Ceramaret is known across numerous industries for its expertise in ceramic production. “Achieving near-net-shape is a proficiency Ceramaret particularly prides itself on, as does Xjet,” Middleton says. “Our technology achieves it through a combination of unique capabilities, from NanoParticle Jetting to our postprocessing steps, whether geometries are simple or complex.”

XJet uses nano particles to deliver extremely fine detail and accuracy. Meanwhile, the production of internal cavities or channels — typically a labor-intensive postprocessing challenge or sometimes an unattainable feat with other technologies – is rendered straightforward with XJet’s proprietary soluble support material, which simply dissolves away.

Related Content

-

Foundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

-

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

-

BMF Receives FDA Clearance for UltraThineer Dental Veneer Material

The zirconia materials are now qualified for use in the production of the world’s thinnest cosmetic veneers, which require significantly less tooth preparation or grinding, thereby preserving more of the patient’s natural enamel.