Carbon Acquires ParaMatters

The acquisition is said to expand Carbon’s generative design software capabilities to enable increased automation and the creation of more complex, higher performance part designs in additive manufacturing.

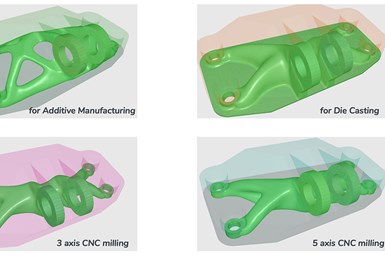

Carbon, a 3D printing technology company, has acquired ParaMatters, a generative design software provider for additive manufacturing (AM). This acquisition expands Carbon’s current software capabilities to include topology optimization. Carbon’s technology platform now broadens to enable product design and development teams to create better products in less time using a wide variety of materials and production systems, the company says.

According to the company, most software platforms used for designing and manufacturing products are optimized for constraints imposed by traditional manufacturing, including injection molding, casting and subtractive processes. The lack of modern design software that can quickly iterate and take advantage of the benefits of AM continues is said to constrain the product development life cycle. This acquisition is said to address this gap and expands Carbon’s generative design software capabilities to enable increased automation and the creation of more complex, higher performance part designs. These benefits are said to build on Carbon’s introduction of Design Engine earlier this year which is used to automate the process of developing latticed parts for production.

“We recognize the critical role software design tools play in our customers' digital transformation. For far too long, designers have settled for software design tools that adhere to the limitations of traditional manufacturing,” says Phil DeSimone, Carbon co-founder and member of the Office of the CEO. “Many design tools of yesterday are not optimized to take advantage of industry innovations, including advanced 3D printing materials and manufacturing processes.”

Both Carbon and ParaMatters say they have shared the same vision to provide modern tools to ensure product development teams can create better products in less time. “Software is the backbone of our idea-to-production platform and we believe the generative design capabilities from ParaMatters are a key expansion of our design software,” says Craig Carlson, Carbon chief technology officer and member of the Office of the CEO. “By expanding our software capabilities that are optimized for additive manufacturing, we are empowering a generation of designers and developers to create better end-use products with advanced geometries and improved performance characteristics.”

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Video: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

-

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.