Airtech’s Dahltram Resins Approved for Use on All Pellet-Fed Titan Robotics Atlas Printers

In this collaboration, Dahltram resins are being utilized for printing on Titan’s Atlas platforms to validate mechanical properties and performance.

Airtech is collaborating with Titan in the development of new materials and expanded functionality.

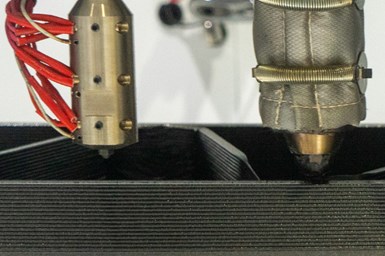

Airtech Advanced Materials Group has partnered with Titan Robotics to provide Dahltram resins for use on all pellet-fed Titan Atlas printers. This expanded offering for additive manufacturing (AM) is designed to drive innovation, development and testing in the AM market.

As a manufacturer of industrial 3D printers and an AM solutions provider, Titan’s technology and product offerings are designed to enable customers to use 3D printing in their production processes — from manufacturing existing products more cost-effectively to making new products. As this partnership continues to produce technological advances, Airtech will continue its collaboration with Titan in the development of new materials and expanded functionality, the company says.

In this collaboration, Dahltram resins are being utilized for printing on Titan’s Atlas platforms to validate mechanical properties and performance in use at Airtech’s company headquarters. Airtech’s Dahltram range of resins are said to be well suited for multiple print platforms, providing production flexibility with end-use material validation. As this partnership supports advancements in AM, Airtech will continue to focus on demonstrating performance in composite, metal and direct-to-part fabrication.

Related Content

-

Robot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

-

Evaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

-

3D Printed Preforms Improve Strength of Composite Brackets: The Cool Parts Show Bonus

On this episode, we look at a pin bracket for the overhead bin of an airplane made in two composite versions: one with continuous fiber 3D printed reinforcements plus chopped fiber material, and one molded from chopped fiber alone.