3MF Consortium Releases Beam Lattice Specification Extension

The software extension provides a solution for storing and transferring lattice-type geometry information.

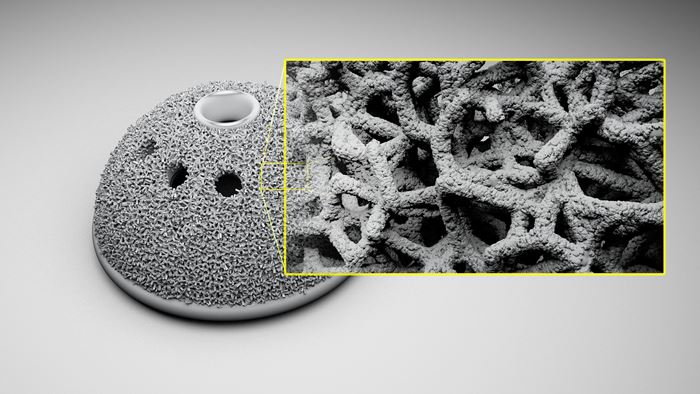

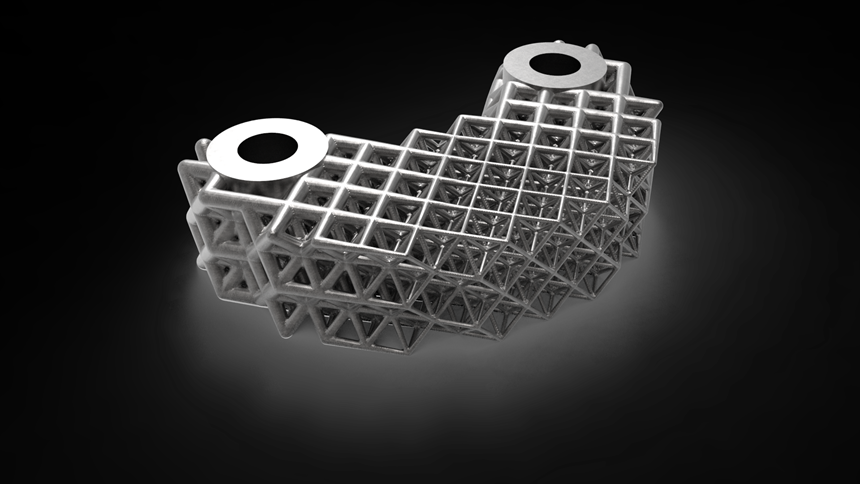

The 3MF Consortium has ratified and released a Beam Lattice Specification extension to its Core Specification. The extension stores and transfers lattice-type geometry information. By providing support for beam lattices, it solves interoperability issues and provides a solution to a problem that is not easily addressed in other file formats. Its benefits include improved design flexibility, lower material costs and reduced production time.

Designers and engineers can use the extension to design part interiors that were impossible to produce a few years ago. As the extension inherits all the features from the Core Specification, it retains build information, colors, materials and technology-specific characteristics like support structures in one file. The extension is available to download here.

The extension is designed to enrich the geometry notion of 3MF with beam lattice elements that can represent small-scale lattices as well as larger truss structures, both of which are inefficient for handling mesh representations, especially when the element count grows into large numbers.

This is the fourth specification extension, furthering 3MF’s goal of providing a universal specification that serves as the backbone of the additive manufacturing ecosystem, and enables companies to focus on innovation rather than basic interoperability issues. The consortium provides open source code free of charge to reduce the barrier to adoption.

Related Content

-

3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

-

Robot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

-

User-Friendly Mass Spectrometry Tool to Enable AM

The Massbox is a technology designed to simplify mass spectrometry by bypassing the need to send samples to the lab for characterization and testing purposes. Exum Instruments’ debut tool is suitable for AM as it can assist with quality assurance, material characterization and failure analysis.