3D Printing Method for Complex Metal-Plastic Composite Structures

Researchers from Japan and Singapore have developed a new 3D printing technique to create precise patterns on the external and internal surfaces of 3D plastic structures.

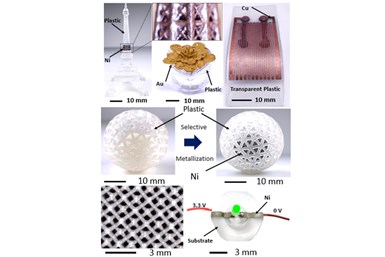

Examples of 3D metal-plastic composites that can be prepared by the new technology. Photo Credit: Professor Shinjiro Umezu from Waseda University

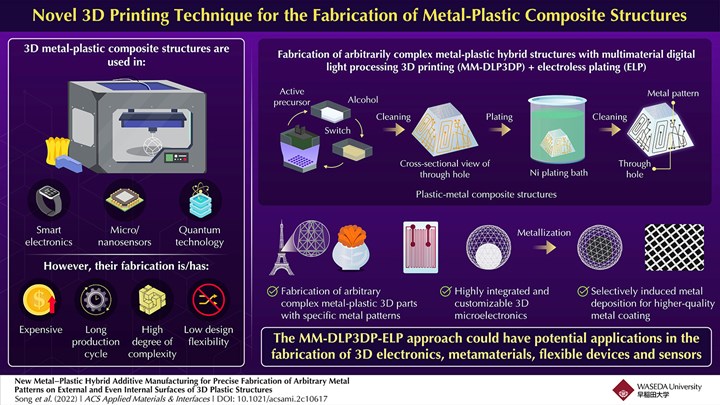

In recent years, research interest in the 3D printing of metal patterns on plastic parts has grown exponentially, due to its high potential in the manufacturing of next-generation electronics. But fabricating such complex parts through conventional means is not easy. Now, researchers from Japan and Singapore have developed a new 3D printing process for the fabrication of 3D metal-plastic composite structures with complex shapes.

Three-dimensional (3D) metal-plastic composite structures have widespread potential applicability in smart electronics, micro/nanosensing, internet-of-things (IoT) devices and even quantum computing. Devices constructed using these structures have a higher degree of design freedom, and can have more complex features, complex geometry and increasingly smaller sizes. But current methods to fabricate such parts are expensive and complicated.

Recently, a group of researchers from Japan and Singapore developed a new multimaterial digital light processing 3D printing (MM-DLP3DP) process to fabricate metal-plastic composite structures with arbitrarily complex shapes.

Robots and IoT devices are evolving at a lightning pace. Thus, the technology to manufacture them must evolve as well, according to the study’s lead authors Professor Shinjiro Umezu and Kewei Song from Waseda University, and Professor Hirotaka Sato from Nanyang Technological University, Singapore.

Although existing technology can manufacture 3D circuits, stacking flat circuits is still an active area of research. The researchers wanted to address this issue to create highly functional devices to promote the progress and development of human society. The study has been published in ACS Applied Materials & Interfaces.

The MM-DLP3DP process is a multistep process that begins with the preparation of the active precursors — chemicals which can be converted into the desired chemical after 3D printing, as the desired chemical cannot be 3D printed itself. Here, palladium ions are added to light-cured resins to prepare the active precursors. This is done to promote electroless plating (ELP), a process that describes the auto-catalytic reduction of metal ions in an aqueous solution to form a metal coating. Next, the MM-DL3DP apparatus is used to fabricate microstructures containing nested regions of the resin or the active precursor. Finally, these materials are directly plated, and 3D metal patterns are added to them using ELP.

The research team manufactured a variety of parts with complex topologies to demonstrate the manufacturing capabilities of the proposed technique. These parts had complex structures with multimaterial nesting layers, including microporous and tiny hollow structures, the smallest of which was 40 micron in size. Moreover, the metal patterns on these parts were very specific and could be precisely controlled. The team also manufactured 3D circuit boards with complex metal topologies, like an LED stereo circuit with nickel and a double-sided 3D circuit with copper.

According to the researchers, using the MM-DLP3DP process, arbitrarily complex metal-plastic 3D parts having specific metal patterns can be fabricated. Furthermore, selectively inducing metal deposition using active precursors can provide higher quality metal coatings. Together, these factors can contribute to the development of highly integrated and customizable 3D microelectronics.

Researchers say the new manufacturing process promises to be a breakthrough technology for the manufacturing of circuits with applications in a diverse variety of technologies, including 3D electronics, metamaterials, flexible wearable devices and metal hollow electrodes.

- Listen to this AM Radio podcast with Stephanie Hendrixson and Products Finishing’s Scott Francis who discuss how conventional finishing techniques like electroplating and powder coating have a role to play in additive manufacturing.

Related Content

BPMI Chooses Velo3D Metal 3D Printing System to Produce Parts for U.S. Naval Nuclear Propulsion Program

The fully integrated 3D printing solution will be operated by ATI in a newly established facility that will provide the U.S. Naval Nuclear Propulsion Program with alternatives to cast parts.

Read MoreIn Casting and Molding, AM Simplifies Conventional Manufacturing

In new ways, additive processes are streamlining and enabling metal casting and plastic injection molding.

Read More3D Printing Solutions to Support Investment, Sand Casting

3D Systems is highlighting a design strategy for better investment casting patterns, as well as a new machine suitable for the production of patterns for sand casting.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More