Is Your Dentist a Manufacturer?: The Cool Parts Show #10

Dental devices have always been custom, but 3D printing is disrupting how they are made. We go inside a dental lab in this episode of The Cool Parts Show.

Share

Dental devices have always been custom-made to fit the patient, but traditionally this process involved analog steps like taking impressions, pouring plaster models and carving wax by hand. With the advance of 3D scanning technology, CAD, CNC milling, and now, 3D printing, dentistry is going digital. Devices can now be custom-built based on intraoral scan data, and delivered to the patient in days instead of weeks.

In this episode of The Cool Parts Show, we visit Spectrum Dental Printing, a lab embedded within a dental practice, to learn how 3D printing allows it to produce occlusal mouth guards faster and more repeatably than they could be made conventionally. Watch the episode to learn more about this digital dentistry workflow and witness one of our intrepid hosts braving the dentist’s chair. | Season 2 of The Cool Parts Show brought to you by Carpenter Additive.

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Transcript

Stephanie Hendrixson

Have you ever thought of your dentist as a manufacturer? We're looking at how a dental lab is improving the patient experience with 3D printing. In this episode of The Cool Parts Show.

Pete Zelinski

Season 2 of The Cool Parts Show is brought to you by Carpenter Additive. We’re touring their Emerging Technology Center in Athens, Alabama. Stick around at the end of this episode—we’re going to talk about heat treating and machining. Now back to the show.

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Pete Zelinski

And we're with AdditiveManufacturing.Media.

Stephanie Hendrixson

This is The Cool Parts Show.

Pete Zelinski

So this is our show all about cool parts made by manufacturers made through 3D printing. And yet, Stephanie, I'm looking at what you brought us and I'm seeing teeth.

Stephanie Hendrixson

That's right. So the teeth that you're seeing, this model was 3D printed. But the thing we're going to talk about mostly today is the mouth guard here. Both of these items were 3D printed and the guard is made for this exact set of teeth.

Pete Zelinski

So I guess some of what I'm feeling is we're headed into another mass customization story, which is really cool.

Stephanie Hendrixson

So you're sort of right. It is another story where the product is being made to a specific individual on demand. It's something that's enabled by scanning technology just in the last couple of years. But where it's a little bit different is that mouth guards and dental devices like these have always been custom made. The difference is that with 3D printing, they're getting away from this really manual analog process and moving into a digital dentistry workflow.

Pete Zelinski

So basic questions. You called this a mouth guard. Tell me more about it. What's this for?

Stephanie Hendrixson

OK. So technically, this is an occlusal guard. This is the kind of mouth guard you'd wear, like if you grind your teeth at night or maybe you've got some dental work that you need to protect.

Pete Zelinski

It's 3D printed. Tell me more. What kind of 3D printing process?

Stephanie Hendrixson

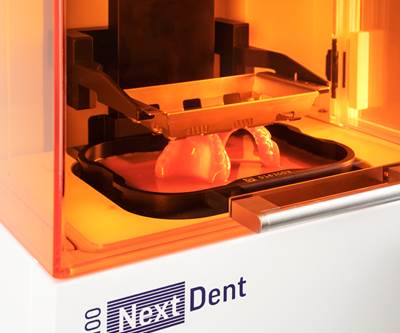

So both the model and the mouth guard were made with a Formlabs Form 2, so a stereolithography process where you've got the vat of resin and the build plate that's rising as the resin is being cured. Both were made by a company called Spectrum Dental Printing. And that's a 3D printing dental lab that spun out of Spectrum Dental and Prosthodontics. So I want to introduce you to Dr. Bradley Purcell, the president and CEO, and Sarah Wells, the COO, to explain how the printing business got started.

Sarah Wells

Spectrum Dental Printing got started as kind of a off branch piece of Spectrum Dental and Prosthodontics. We bought some printers in the practice to kind of use in-house to utilize some of the digital scanning technology that we already had.

Bradley Purcell

The problem is with models is they break they chip, they abrade, the patient has to come back in. And we thought, gosh, if we have the digital image why can't we just make some out of plastic that if it broke, we could just print it again? And so we said, well, why don't we just get a printer? All of a sudden we could create a model. It was less effort. It was saved to the cloud and we realized the power from that. And from there we realized, geez, we don't have to stop here. With this program we have it says we can make bite guards and surgical guides and dentures and temporaries and all these other things. So why don't why don't we try to do that?

Pete Zelinski

So are these your teeth?

Stephanie Hendrixson

OK. So those are not my teeth, but I did have a mouth guard 3D printed. So I went to Spectrum to find out how 3D printing is changing the process for devices like this.

Pete Zelinski

I'm not going to ask you to put that in, but I mean, I am interested. Tell me all about it. Where do you want to start?

Stephanie Hendrixson

So I guess I'll start where it starts for most patients, in the dentist’s chair. So at Spectrum they use an intraoral scanner made by 3Shape and it's about the size of your electric toothbrush. So there's a technician who will just kind of move that scanner around your mouth and it's just really rapidly capturing all of these images of your teeth and your gums. And so you get to see like this digital rendering of your mouth. They take that data cloud and do some processing to arrive at an STL file that goes to the printer. Once these are printed, you know, it only takes a couple hours. There's really light, minimal postprocessing that happens and then it's ready to go.

Pete Zelinski

So in listening to you talk about that and then seeing the footage, a couple of things strike me. I guess one of them is how additive manufacturing needs data. Right? We keep encountering that. Particularly these mass customization applications, these these tailor-made products. What makes them possible is 3D printing, but that's not all of it. What makes them possible also is the level of measurement and scanning technology we've come to. And so I'm watching that scanner that they were using while you were in the dentist chair and it's amazing. Just seeing, yeah, seeing this actual is super accurate rendition of the inside of your mouth take form. That's one thing I saw.

Another thing is how additive manufacturing makes it possible to produce within this really compact space. So Spectrum is making these dental devices for its patients and for the patients of other dentists and they don't think of themselves as a manufacturer, but they're doing all that production in that little fleet of 3D printers. That's like sitting on part of a tabletop.

Stephanie Hendrixson

Yeah. So hold that thought because we're gonna get to that a little bit later.

Pete Zelinski

OK.

Stephanie Hendrixson

But what I want to kind of emphasize now is how fast and efficient the process is when you think about how they had to do it previously. So before all this digital technology, if you needed a mouth guard like this, you'd have to go to the dentist and they'd take an impression. So if you had braces or anything like that, they've got like that tray of sort of putty material and you've got to put it in your mouth and kind of hold it there. It's not very comfortable. They pull that out and then they pour dental stone, that kind of plaster material, into it to make the model.

Well, if you need a mouth guard, what happens then is that model becomes a thermoform tool. So they've got a sheet of acrylic. They're heating it up and then forming it down over that model. And then as a result of actually getting the device off, you're probably going to destroy the model. It's sacrificial tooling, basically. And so there are all these manual steps and there are actually a lot of things that can go wrong in that process. So here's Sarah describing some of the problems you might have.

Sarah Wells

There's a lot of things that can go wrong. First thing is just getting a really good first impression. You know, if the patient is gagging, or they move. The material is really temperature sensitive so if it sets up too fast, if you don't get everything in that first impression, you have to start over. From there second is having a really good pour. If you have bubbles in your stone when you're poor, you'll get bubbles in the model and it won't be accurate. Or you could knock the model off the counter when you turn around and break it. When you actually fabricate the occlusal guard, when it sucks down over the stone, typically that destroys your model. So when you try to take that plastic back off of that stone, 90% the time you're going to break the teeth off. So if you didn't get it perfectly, or as you're trimming it you nick a spot, it's starting back over at that impression appointment, which of course, patients do not like to get a phone call that they need to come back and do those impressions over again.

Stephanie Hendrixson

So by moving to 3D printing for a device like this, you're getting something that's easier to make, it's faster, it's more accurate and it's also more repeatable, easier to replace.

Pete Zelinski

So I'm hearing all those advantages. Right? But I'm looking at this and I'm thinking about this as a patient. You know, so long ago I did have braces and that goop up in your mouth, I had that. And you're describing a way of doing this that for the patient is way more comfortable.

Stephanie Hendrixson

Oh, yeah. So that's a huge part of it. So Dr. Purcell had some things to say about how this improves patient experience.

Bradley Purcell

Well, first, the patient experience is so much more pleasant and that in of itself, creating a better experience for the patient, is worth it alone because everything is less tense. And what happens is just it's less taxing on the body. It's more efficient. When you're patients more comfortable you can work faster. Which they enjoy as well. Impressions were always kind of this nefarious thing that gave us issues and you'd make them, and you remake them, and the poor patients gagging and these things. And now with digital, you always get the impression. There is no missed impression. You see it. It's right there. It's more comfortable. It's far faster. What typically takes five minutes in the mouth. We can do a whole mouth in almost a minute. A half.

Pete Zelinski

OK. So earlier I noted there's a fleet of printers and they're doing what looks to me like a whole lot of, call it production, right in a small area, small amount of space. And you said, hold that thought. I'm still holding that thought. What do you got?

Stephanie Hendrixson

All right. So Spectrum Dental has obviously seen the benefits of this for their technicians and for their patients. They're now offering their printing services to other dental labs as well. And the business is kind of taking off. So they're actually they're getting ready to add new technologies, more printers, and they're going to move into a dedicated space just for the printing business. So it's going to start to look a little bit more like manufacturing the way we normally think about it.

Pete Zelinski

OK, so you started by talking about how something that never occurred to me, but dentists have always been making tailor-made products. They've always been manufacturers, kind of, custom manufacturers. Now you're describing a system where this dental practice really will become a manufacturer. They have this digital workflow process that is enabling them to become a manufacturer and now serving other dental practices.

Stephanie Hendrixson

That's right. And it's going to be faster, easier and a lot more repeatable. So you can have that that guard made or maybe remade at a moment's notice.

Pete Zelinski

All right. I think I got this. Occlusal guard—mouthguard—3D printed, made through stereolithography. This process, it's enabled by scanning technology. The measurement technology had to get sophisticated enough to give all the data that 3D printing would need to make a really accurate, customized mouth guard. But now that that scanning technology exists, 3D printing is possible as a way of realizing a tooling less procedure for making this mouth guard. The process is digital now. It's more accurate. It's way more comfortable for the patient. And if you need a new guard, you don't have to take another impression you just hit the button again and start the process again. And maybe most significantly of all, for the future and for Spectrum Dental, this idea is going bigger. They're becoming a bigger, broader manufacturer that can take patient data from scans like this and make mouth guards, make other dental devices for a whole range of other dental practices.

Stephanie Hendrixson

Yeah. So I think you got it. That's it for this episode of The Cool Parts Show. If you want to learn more about Spectrum Dental Printing you can find our story about them in the show notes or at additivemanufacturing.media.

Pete Zelinski

Email us if you wanna talk about the show. If you've got a cool part you'd think might make a great episode. coolparts@additivemanufacturing.media.

Stephanie Hendrixson

And if you like the show, we hope you'll subscribe. Thanks for watching.

Pete Zelinski

I'm at Carpenter Additive's Emerging Technology Center in Athens, Alabama. Contract additive manufacturing facility. All the steps in house for complete additive production.

A metal 3D printed part isn't done after the 3D printing. On the outside, fine tolerances, which is why Carpenter has extensive machining capability. But then on the inside, stresses from the additive build that potentially need to be relieved. Machining and heat treating go together. Carpenter engineers think about how to apply them both, and what sequence to apply them in.

Andrew Holliday

You might do heat treatment before or after machining depending on your material as well as your finished part. So you might have a rough machining step and then you want to harden it afterwards and do a finished machining step. This is to make it easier on our machinist as well as to make sure our parts are the highest quality possible. So naturally during the additive process you're welding each layer together. You have a lot of heat being pumped through that part. So if you were to cut it off the plate directly afterwards, you might have deformation, bending or other defects. So the first heat treatment we usually like to do is called stress relief, which basically just relieves those internal and residual stresses from the actual printing process. Now the other things you might want to do is something like a solution treatment. and you also have things like aging or hardening that we can also do in-house.

Related Content

Ultra-Complex 3D Printed Scaffolds Enable Cell Growth: The Cool Parts Show #70

Perhaps the ultimate surface-area challenge is in bioengineering: creating structures that can grow sufficient cells within a compact volume to be effective for leading-edge medical treatments. The Southwest Research Institute develops bioreactor scaffolds that could only be made using 3D printing.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreFDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MoreOvercoming Challenges with 3D Printing Nitinol (and Other Oxygen-Sensitive Alloys) Through Atmospheric Control

3D printed nitinol has potential applications in dental, medical and more but oxygen pickup can make this material challenging to process. Linde shares how atmospheric monitoring and the use of special gas mixtures can help maintain the correct atmosphere for printing this shape alloy and other metals.

Read MoreRead Next

Dental Lab Brings 3D Printing into Digital Dentistry Workflow

With 3D scan technology and resin-based 3D printers, Spectrum Dental Printing is changing the way dental devices are made — and potentially, how dentistry happens.

Read More3D Printed Custom Glasses: The Cool Parts Show #8

Fitz Frames has reimagined glasses, from the frames to the ordering process. See how the company manufactures glasses customized to every face in this episode of The Cool Parts Show.

Read More3D Printing Is the Next Step for Digital Dentistry

Digital dentistry is a workflow rather than a single technology. A conversation with Rik Jacobs of 3D Systems explores how 3D printing is participating in and advancing this workflow.

Read More

.jpg;width=70;height=70;mode=crop)