Flexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.

Share

This episode of The Cool Parts Show brought to you by Carpenter Additive

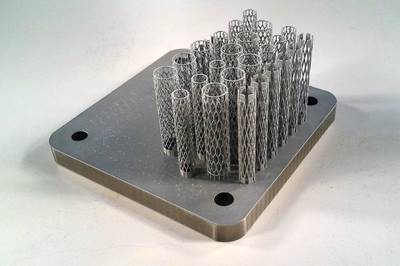

Metal bellows are flexible metal junctures for connecting machine components that might need to expand or move. They are typically manufactured by forming tubes of sheet metal, but this process relies on tooling that limits design possibilities and can make the bellows costly. Mechanical engineer Günter Kappler has developed metal bellows that can instead be manufactured via laser powder bed fusion. After designing and 3D printing multiple iterations of these parts, Kappler ultimately landed on a solution that looks quite different from a standard round bellows, but has performed comparably in testing. See the design (as well as some other iterations created along the way) and learn what it takes to 3D print flexible metal components in this episode.

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- Günter Kappler Engineering

- Hirschvogel Group, the German automotive company that helped with 3D printing the metal bellows

- Another example of flexible metal 3D printed components (in this case, the flexibility is achieved through the use of a shape memory alloy)

- Scroll down in this piece for photos of other 3D printed bellows, in this case made from flexible thermoset polymers

Transcript

00:00:00:00 - 00:00:00:22

Pete Zelinski

I'm Pete.

00:00:00:22 - 00:00:06:22

Stephanie Hendrixson

I'm Stephanie. And this is The Cool Parts Show, our show all about innovative, unusual, unique 3D printed parts.

00:00:06:22 - 00:00:11:23

Pete Zelinski

This solid steel part is bendy by design.

00:00:11:23 - 00:00:15:21

Stephanie Hendrixson

Flexible metal bellows on this episode of The Cool Parts Show.

00:00:20:20 - 00:00:24:15

Stephanie Hendrixson

This episode of The Cool Parts Show is brought to you by Carpenter Additive.

00:00:24:15 - 00:00:34:16

Stephanie Hendrixson

The company's PowderLife solution is a combination of hardware and software technologies designed to help AM users manage their metal powders. Stay tuned after the episode for more on how the system works.

00:00:34:16 - 00:00:36:15

Pete Zelinski

Welcome to The Cool Parts Show.

00:00:36:15 - 00:00:41:21

Stephanie Hendrixson

If you like what you see, make sure to subscribe and hit that bell icon on YouTube to get notified about new episodes.

00:00:41:21 - 00:00:46:00

Stephanie Hendrixson

Today on the show, we're going to be talking all about these flexible metal bellows.

00:00:46:00 - 00:01:02:02

Pete Zelinski

Right. Bellows, here is an example of one made conventionally. A metal bellows is a flexible metal juncture for connecting machine components that need to move relative to one another.

00:01:02:02 - 00:01:20:16

Pete Zelinski

So a bellows could be an expansion joint. It could be part of a mechanical seal, it could be a pump component. Lots of different types of machines use different types of bellows, including some very sophisticated machines. But this is a hard component to produce.

00:01:20:16 - 00:01:31:05

Stephanie Hendrixson

That’s right. So conventionally made bellows like this one, typically you would start with tube or sheet metal kind of formed into a cylinder and then you would kind of like pinch those ridges in using some type of tooling.

00:01:31:11 - 00:01:43:05

Stephanie Hendrixson

So this is a process that you are kind of limited to the tooling. So you can’t easily produce different variations, make bellows in different diameter, stuff like that, without potentially retooling the entire process.

00:01:43:05 - 00:02:01:01

Pete Zelinski

A costly manufacturing process. It's a joining process involving tooling. But we met someone who sees metal 3D printing as a way to realize a different, more flexible, more cost effective way to make metal bellows.

00:02:01:01 - 00:02:03:11

Stephanie Hendrixson

Yeah. So let's introduce Günter Kappler.

00:02:03:11 - 00:02:18:05

Stephanie Hendrixson

He has a background in mechanical engineering, and he has been working to identify and develop applications for additive manufacturing through his company in Günter Kappler Engineering. So metal bellows or flexible metal components like this are one of those big opportunities.

00:02:18:05 - 00:02:40:08

Dr. Günter Kappler

Well, metal bellows are used as flexible elements. The flexibility of these elements is realized mechanically in the form of elastic, single or multilayered, thin-walled corrugated bellows with an underlying diameter. These parts are installed among other things, as compensators in pipelines for gaseous and liquid media to compensate for relative movements and vibrations.

00:02:40:08 - 00:03:17:11

Dr. Günter Kappler

The relative movements and vibrations occur during operation, for example, due to the unbalance of rotating components, dynamic load changes, moments of inertia or thermal length changes or whatever you name it. Current solutions are highly standardized. You know, instead of adapting to the adjacent components, the adjacent components often have to be adapted to the flexible elements. From a commercial point of view, the specific prices for these parts reach up to €250 per kilogram, which also makes them very interesting for additive manufacturing.

00:03:17:11 - 00:03:30:18

Stephanie Hendrixson

So if you can get away from that standardization, there's the chance to adjust and manipulate some of these variables and make different types of bellows and 3D printing, specifically, laser powder bed fusion is a promising manufacturing alternative.

00:03:30:18 - 00:03:42:13

Pete Zelinski

Right. So what do we know about 3D printing? It is a tooling less process and getting away from that need for tooling opens up the chance for adaptability, customization.

00:03:42:13 - 00:03:58:17

Pete Zelinski

But this is a sophisticated component, a complex component, like look at this conventional form. This particular challenge is how do you orient a form like this for 3D printing so that there is no surface

00:03:58:17 - 00:04:08:08

Pete Zelinski

presenting overhangs that need support structures because in laser powder bed fusion, those support structures could present a challenge to making a part like this.

00:04:08:08 - 00:04:38:23

Dr. Günter Kappler

So in the area of thin walled bellows, support structures are disadvantages in several aspects. First, they add stiffness to the system if they cannot be completely removed. Second, they affect the surface of the highly stressed components, which ideally should be completely smooth. And third, the removal of increased support structures and complex geometries has significant cost disadvantages. So the first development phase focused on building the circular bellows upright.

00:04:38:23 - 00:04:50:13

Stephanie Hendrixson

so simply recreating the conventional bellows and printing them straight up and down like this was not really an option because you would have needed support structures between all of these little ridges to support all of the overhangs.

00:04:50:18 - 00:05:08:03

Stephanie Hendrixson

And that means you also have to then remove all those support structures in postprocessing and it gets really complicated. So the next version of bellows that Gunter started to work on looked more like these. So helical bellows. Print the ridges at an angle and so you avoid having those support structures. But these had their own challenges.

00:05:08:03 - 00:05:18:01

Pete Zelinski

Yeah. So this form could be 3D printed, but it's not flexible in the way that a bellows needs to be.

00:05:18:01 - 00:05:32:23

Dr. Günter Kappler

Although this design was undoubtedly the best looking and also achieved significant flexibility advantages, it did not at any value to the state-of-the-art solutions. So the breakthrough came with the realization that the bellows should not be circular.

00:05:33:07 - 00:05:43:22

Pete Zelinski

We are accustomed to additive manufacturing being a way that you get away from straight lines and boxy forms, but in this case, a 3D printed square was the answer.

00:05:43:22 - 00:05:51:13

Stephanie Hendrixson

Right. So getting past the assumption that bellows need to be round allowed Gunter to get to this design, which works as a functional bellows.

00:05:51:18 - 00:06:05:08

Stephanie Hendrixson

He also got away from the idea of printing them straight up and down. So these actually get printed on their side at an angle to avoid any potential support structures that might be needed. And figuring out how to do this now opens up other types of design possibilities.

00:06:05:08 - 00:07:00:04

Dr. Günter Kappler

So the flexible element is now built up, lying down and rotated by 45 degrees. This results in elliptical to rectangular bellows cross-sections. Support structures are completely avoided with the exception of the point fixations on the outer contours of the bellows resting on the powder bed. By using a more rectangular design and a horizontal construction, it was not only possible to avoid support structures, but there was suddenly a great deal of design freedom for the individual design of the bellows with excellent flexible properties. A large number of FEM simulations were therefore performed with numerous geometric detail modifications to the bellows design. Ultimately, the influence of the wall thickness, the bellows height, the bellows length, as well as its geometry, was scrutinized to realize an optimized design.

00:07:00:04 - 00:07:31:21

Pete Zelinski

In general, laser powder bed fusion can 3D print a feature without any supports up to an angle of 45 degrees. And so when this form is oriented this way, there is no surface that is more than 45 degrees from vertical. This was made from stainless steel 3D printed on a machine from SLM Solutions. Gunter worked with the Hirschvogel Group, which is an automotive parts producer, to get this made.

00:07:31:21 - 00:07:43:07

Stephanie Hendrixson

But of course it is one thing to design and even manufacture a flexible metal bellows. It's a different thing entirely to put it to the test against a conventional version.

00:07:43:07 - 00:07:59:23

Dr. Günter Kappler

Once it was determined that the design could match the properties of the conventional metal bellows, prototype parts were fabricated to test and directly compare them in a vibration test. The objective of the test was to realize the allowable displacement of the

00:07:59:23 - 00:08:06:14

Dr. Günter Kappler

conventional the manufactured flexible element of plus minus ten millimeters for 1000 cycles without any damage.

00:08:06:20 - 00:08:22:08

Dr. Günter Kappler

Both the conventional and the two 3D printed test specimens survived 1000 cycles without any damage. In addition, the 3D printed specimen were subsequently successfully tested with 50% more displacement over 1000 cycles.

00:08:22:08 - 00:08:37:23

Dr. Günter Kappler

The test provided reproducible results consistent with the previous FEM simulations. Thus this prototype test was the first functional proof that flexible metallic elements can be manufactured additively.

00:08:37:23 - 00:08:58:05

Pete Zelinski

So functional proof. This simple square design promises to open up considerable design freedom for mechanical designers using bellows and cost savings as well. Gunter lists some of what a 3D printed metal bellows might make possible.

00:08:58:05 - 00:08:59:15

Dr. Günter Kappler

First, you can do any tube diameter.

00:08:59:21 - 00:09:48:17

Dr. Günter Kappler

Second, the tube diameter can be variable along the flexible element. Third, you can realize variable specific ductility due to the different bellows heights or wall thicknesses along one element. Number four the flexible elements can be axle or follow a curved spline and fifth, you can realize a design with any flanges as an integral part without welding. So there is no need to adapt the pipe system to the Compensator anymore, but the Compensator is adapted to the given interfaces of the pipe system. And commercially due to the high specific price of up to €250 per kilogram of the conventional bellows. There are already some good applications even for direct replacement existing today.

00:09:48:17 - 00:09:57:18

Dr. Günter Kappler

However, a significant advantage is that the additive flexible element can be designed almost arbitrarily for any customer requirements.

00:09:57:18 - 00:10:18:03

Pete Zelinski

With that last point, Gunter is pointing out how some bellows made conventionally and some systems are already costly enough that additive manufacturing right from the get go represents a cost savings and potential benefits, like adapting the design, customizing the design. All that can come later.

00:10:18:07 - 00:10:33:08

Stephanie Hendrixson

Yeah. A lot of times the issue of cost is sort of an argument against 3D printing. But here conventional bellows in a lot of cases are expensive enough already that just changing the process to 3D printing might get you some savings and then you have these other benefits and advantages as well.

00:10:33:08 - 00:10:45:02

Stephanie Hendrixson

All right. These are 3D printed metal bellows made through laser powder bed fusion from stainless steel. This is an example of how 3D printing can be applied to produce flexible metal components.

00:10:45:02 - 00:11:04:19

Pete Zelinski

Conventional metal bellows are round. They're typically round because they're made using tooling, and this is the optimum form for that manufacturing process. It turns out there's no reason why they have to be round and a square profile of the metal bellows produces a form that is conducive to 3D printing.

00:11:04:19 - 00:11:11:17

Stephanie Hendrixson

This idea is still in development, Gunter is still going through fatigue testing and some other types of testing for these components.

00:11:12:04 - 00:11:16:07

Stephanie Hendrixson

But he's starting to look for the first use cases for parts like this.

00:11:16:07 - 00:11:31:19

Pete Zelinski

If you have a machine component like a bellows or a linkage or a carrier or a bracket that you've made more effectively through additive manufacturing, we live for this stuff. Email us CoolParts@AdditiveManufacturing.media.

00:11:31:22 - 00:11:42:00

Stephanie Hendrixson

And if you want more from this episode, check out the All Access page at TheCoolPartsShow.com. So signing up is free and easy. Just go to TheCoolPartsShow.com/AllAccess.

00:11:42:00 - 00:11:43:11

Pete Zelinski

Thank you for watching.

00:11:43:11 - 00:12:10:16

Stephanie Hendrixson

Thanks again to our sponsor Carpenter Additive. In addition to supplying metal powders, the company also offers services, software and hardware to help AM users manage their powder. One example is the PowderLife System, a combination of cloud based tracking software with hardware designed to make powder handling easier. Two key components are the PowderLife Hopper and the automated docking station. Luke Boyer, manager of PowderLife Applications and Andrew Holliday, applications engineer, explained how the system works.

00:12:11:00 - 00:12:40:00

Luke Boyer

Today, when a user of additive manufacturing is receiving powder, they oftentimes receive it in either

five, ten, 15, maybe a 20-kilo bottle. But they're receiving pallets of them and you're receiving ten, 20, 50, 100s of these bottles. The user has to look and segregate and store them appropriately so the bottles don't get mixed up. And it requires a lot of lifting and moving and labor. The components of PowderLife are all based around making the powder management systems and the added manufacturing shop for easier to use for the operator, cleaner, as well as more traceable.

00:12:51:23 - 00:13:13:08

Andrew Holliday

Three of those basic parts of PowderLife are our PowderLife hoppers or our storage containers for powder. The second would be automated docking systems that allow material to be pushed in and out of machines with no human contact. The third would be our PowderLife Online software system that allows you to trace this powder as it goes through your shop floor.

00:13:13:08 - 00:13:31:14

Luke Boyer

The hardware and the software together just helps really streamline that and improve the final user's experience and let them concentrate on going from design to the part itself. It takes the headache of powder management out of the equation for them.

Related Content

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreRead Next

Flexing Thermoset Polymers Into Production 3D Printing

Chromatic 3D Materials develops tough and flexible thermosetting urethanes for additive manufacturing. The resin formulation is only part of the path to scale.

Read More3D Printed Nitinol Opens New Possibilities for Arterial Stents

Researchers at Australia’s national science agency, CSIRO, have created the first self-expanding nitinol stents made via powder bed fusion. The project points to more opportunities with this shape memory alloy.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More

.jpg;width=70;height=70;mode=crop)