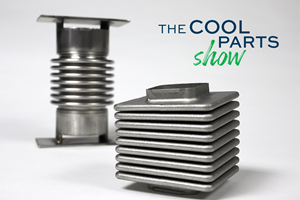

3D Printed Conveyor Mat Aids Automation: The Cool Parts Show #55

Additive manufacturing for long, flexible sections of brush material? On this episode of The Cool Parts Show, how a continuous DLP system provides the answer for a component critical to vibratory automation systems.

Share

Vibratory conveyors and separators use engineered brush mats to channel vibration into motion. After one particular mat product for small, delicate parts was discontinued by its supplier, users like machined part provider Swiss Automation were left without a replacement for a brush mat that, in this company’s case, is critical to the operation of an automated system it has come to rely on. But 3D printing offered the answer: OPT Industries delivered a polymer replacement for this brush mat thanks to a digital light processing system able to create long mat or fabric sections by printing continuously. Watch to see the 3D printed vibratory mat in action. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- OPT Industries

- Swiss Automation

- OPT’s process has also been used to make nasopharyngeal swabs. Here is more on additive manufacturing for swabs.

- Other examples of AM as an aid to automation include 3D printing for end-of-arm tooling and this bracket for a coolant refilling system.

- Swiss Automation actually goes way back with 3D printing. Stephanie visited them years ago for this story.

Transcript

00:00:00:03 - 00:00:00:15

Peter Zelinski

I'm Pete.

00:00:00:23 - 00:00:01:16

Stephanie Hendrixson

I'm Stephanie.

00:00:02:00 - 00:00:10:15

Peter Zelinski

We are at Swiss Automation. They're headquartered in Barrington, Illinois. We are at their Kerry, Illinois facility. They make precision machines parts.

00:00:10:21 - 00:00:25:10

Stephanie Hendrixson

We're standing in front of this automated cell that takes those parts, separates them so that robots can pick and place them to prepare them for downstream processes. We are here to learn what 3D printed fur has to do with this industrial system.

00:00:43:23 - 00:00:45:03

Peter Zelinski

Welcome to The Cool Parts Show.

00:00:45:11 - 00:00:58:08

Stephanie Hendrixson

If you're new to the show, thanks for joining us. And if you like what you see, help us out and hit that subscribe button. But this is our show all about cool, unique, unusual, innovative, 3D printed parts. And today we're going to be applying some of those adjectives to what is basically 3D printed carpet.

00:00:58:17 - 00:01:08:02

Peter Zelinski

It is special carpet. It is a continuously 3D printed mat. Could be any length. This one serves a particular function.

00:01:08:15 - 00:01:21:17

Stephanie Hendrixson

Right. So this is a mat for a vibratory separator. So a piece of equipment that moves or sorts parts by kind of gently shaking them. And the part that we have here in the studio with us is a replacement for a product that is no longer being produced.

00:01:22:05 - 00:02:10:08

Peter Zelinski

So vibratory separators or conveyors use a special carpet or fur that translates the mechanical vibration into motion of whatever parts or objects are being carried along. It is difficult to manufacture and the mats wear out over time. The particular low abrasion version of a mat like this is a product that the original manufacturer no longer supports. But there are still users out there who depend on that product.

We found one user who couldn't find a replacement, and the alternative they found is made by a company in Boston with a distinctive 3D printing system.

00:02:10:18 - 00:02:31:06

Stephanie Hendrixson

All right. So the company we're talking about is OPT Industries, they’re a spin out from MIT. And they've developed this continuous DLP 3D printing technology that allows them to make sheets of structured material like this that can be any length. So this type of technology can be applied to things like faux fur, medical swabs, cosmetic brushes and now industrial carpet.

00:02:31:17 - 00:02:38:12

Peter Zelinski

Let's hear from them. This is Diego Taccioli. He is senior computational designer with OPT Industries.

00:02:39:02 - 00:03:49:12

Diego Taccioli

OPT Industries is a start up that combines computational design with additive manufacturing and polymer science to manufacture materials at the micron scale precision. We've designed and built our own proprietary 3D print hardware that integrates roll-to-roll system with Photolithography. We can fabricate no limitation in length and with no impact on resolution or customizability. We also have an in-house software that allows for fast parametric designs of millions of geometries with little computational requirement.

So designing a fur and fur-like structure is really challenging because with such density it becomes not only a computational challenge where both you have to be able to compute such file size, but also keep a clean computation for the computer to be constantly free enough to design so that it doesn’t get bogged down. Another thing is that that scale, for it to be something that looks and feels in a certain way like fur or something of that nature, needs to have some randomness and a certain amount of spacing and element size that has a good balance of movable fibers while still being able to be printed and not have them stick together into a more of a clump after it's made.

00:03:50:07 - 00:03:58:16

Stephanie Hendrixson

So Diego brings up an important point. The software is a really big part of how they're able to produce parts like this because it's necessary to design in a little bit of randomness.

00:03:58:23 - 00:04:32:18

Peter Zelinski

So that continuous DLP system, that hardware software system. It proved to be just ideal for producing something like this carpet, the geometry and the spacing that the elements need. All of these little fibers or little hairs, each one needs just the right directionality and springy-ness and resiliency to be able to move the objects placed upon it, move it just so in response to the vibration.

00:04:33:12 - 00:04:56:22

Stephanie Hendrixson

So OPT learned about this opportunity with vibratory separator mats through a different company, The Industrial Brush Company. Industrial Brush provides brush products and things like this. They noted that there was a gap in the marketplace and they were looking for a solution. They actually had tried, I think, to manufacture it themselves, but when they saw what it was able to do with other sort of like textile like products, they thought that 3D printing might be the right way to go.

00:04:57:08 - 00:06:13:21

Diego Taccioli

The parts had to move at a certain consistency and speed, and especially a direction where it's specifically targeting linear conveying. The brushes also can’t scratch or damage the parts that are being moved and they can't be falling in between the cracks and getting stuck. Previous products were made with a rubber or urethane based and having fibers glued into them and basically trimmed at a certain height to match the exact need for that particular application.

We basically started with creating a similar geometry and making similar bristle size to spacing without restricting the fibers so that they can perform and act in a very identical way. We realized that we obviously have a different design, material, and production process, so we had to kind of adjust accordingly so that our material can be printed to perform the same and not necessarily look the same.

We don't expect people to rip everything out of their conveyor systems, but actually work in parallel with existing products that are on the conveyors. So we had to basically make a very similarly densely packed brush design that can basically jive with what's out there and needs to be easily cut-ablel and basically adhere with tape onto the surface of the machines.

00:06:14:09 - 00:07:24:13

Peter Zelinski

So this really helps out manufacturers who are using these vibratory systems to move fittings or fasteners. We found a manufacturer like that, Swiss Automation, they're located near Chicago. They make machined parts, small machine parts. And one particular family of parts that they make goes through this automated process where robots grab the components and stage them in just the right way for finishing operations that come later.

It used to be only people were doing them. People were grabbing these parts and setting them up just the right way. Now a robotic system does much of that work in an unattended process, but it's vision guided and the robot can't grab a part effectively if it's touching another part because the vision system can't quite see it well.

So the solution is a vibratory separator just shakes all these components apart, so they're all separate and the robot can grab it effectively. This vibratory separator is really key to the automated process. And Swiss Automation really needed that mat.

00:07:25:07 - 00:07:36:10

Stephanie Hendrixson

Yeah, so this mat was a big deal. So let's hear from Kyle Rogner. He's an engineer at Swiss Automation. He focuses on parts finishing and he can talk more about the importance of this mat to this automation system.

00:07:36:22 - 00:08:56:11

Kyle Rogner

So the system is used as a supplement to the humans stacking the parts, so it's fixturing parts to prepare them to go into a finishing process. The vibratory separator brings parts into the cell, it separates them so the vision system can see them and then the robot can identify them and pick them up.

So the vision system is essential for this process because of the variety of our parts that we have. We vary from very small parts to larger products, but we only have one cell. Traditionally, you would set up the cell to handle one part at a time, but because we needed that flexibility, we'll run three or four parts through every day so we don't have time to swap out components.

The carpeting that we currently have has been in service for three years and we started to see wear on the carpet, which prompted us to look into replacing it where we discovered it was very expensive and discontinued at this point. So that's where we started searching for other options. You know, a few square feet of carpeting was going to be a few grand.

That moment was kind of an eye opener because you think something as simple as carpeting should be relatively cheap. But it not being even available was kind of a scary moment because we just got this thing working, you know? And the first time you need to replace something and it's not available is kind of, you know, imagine driving a car and you can't get an oil filter for it.

00:08:57:03 - 00:09:12:21

Stephanie Hendrixson

So put yourself in Swiss Automation's shoes. You spent all this time, money, resources, setting up this automation system. It works great. You're realizing all of these wonderful benefits, and then you discover that this key piece, this consumable mat, this carpet, is no longer available.

00:09:13:20 - 00:09:29:11

Kyle Rogner

It was kind of scary for a minute, but we were able to find OPT and they were able to work with us and we're getting somewhere now. We had a lot of people say they couldn't help us, or there was no hope in the future. And so this kind of became a lifeboat in a way.

00:09:30:02 - 00:09:48:17

Peter Zelinski

There were some wrinkles to work through. So the robots are guided by a vision system, and this new 3D printed mat is a different color than the previous one was. This is light. The previous one was dark. That created some issues with the vision system. It had to be recalibrated.

00:09:49:08 - 00:11:29:11

Kyle Rogner

We've got two cameras up here. These cameras look down. Each camera is set up to a robot. The robot system communicates between the two of them. Basically, they ask for permission. So this one says, Do I have permission to go in? Is there anything in there? If that robot's away, this one gets permission and it can go in and grab the part.

So with the system set up originally with the green carpeting, we had a very black background with the red lighting and so when we changed to the more white translucent carpet, it changed that vision quite a bit. So we had to have our integrator Methods come in and kind of recalibrate things. Prior, the lights would highlight the parts, but now what they were doing was washing them out so you couldn't tell the difference.

So by doing the math, which utilized the blank table, then we took an image with the parts on it and were able to do the math to remove the table away, leaving us just the parts.

When we first received the new mat, initially looking at it, I thought there was no way it was going to work. The fibers were much more stiff. I didn't really know how much the flexibility of those was going to impact the part movement, but they're also much more dense, and that density kind of concerned me if it would be effective.

You know, if the fibers being at an angle is important, but they're so tightly packed, does that angle actually play a factor anymore or is it just a flat surface? So when we put it in there, it was a little unsure if it would work and it did take a little bit of tweaking the frequency and the amplitude of the vibrations.

But once we got there, it's working fine.

00:11:30:09 - 00:11:49:06

Stephanie Hendrixson

Now that OPT has developed and commercialized the solution, they're looking toward other potential applications. They could take this carpet design and manipulate the bristles in a different way, change the angle, change the density to make parts, move faster or slower to support heavier parts. They're also looking at adapting the solution for a vibratory feeder type application.

00:11:49:15 - 00:12:02:21

Peter Zelinski

And as Swiss Automation thinks about unattended production of other small parts they're going to use vision guided robots, meaning they'll have more use for separators using a mat like this. Want to wrap this up?

00:12:03:12 - 00:12:30:12

Stephanie Hendrixson

So this is a 3D printed mat for a vibratory separator. 3D printed by OPT industries, and it replaces a product that is no longer available. That is an issue because there are companies like Swiss Automation that have systems in place that use these mats. They're consumable and they wear out over time. So there's still a need for this product and OPT is able to not reproduce exactly, but to produce a replacement that works just as well.

00:12:30:20 - 00:13:13:13

Peter Zelinski

This is a component of a separator or a conveyor, but not a conveyor that moves objects along a linear path with linear motion, but instead one that uses vibratory motion transmitted through the furriness of this carpet to achieve the desired motion that way. This carpet form was 3D printed, digital light processing. DLP was used to get the geometry of all of these little furry hairs on this carpet. But what's significant is it is a continuous DLP process. So that a form like this can just be 3D printed, 3D printed, 3D printed to whatever length is needed.

00:13:14:02 - 00:13:59:03

Stephanie Hendrixson

This mat looks different than the one it replaced. It's a different color. The bristles are a little bit different because of the nature of the 3D printing process, but nonetheless it works in the same way as the mat it replaced. There might be some issues with users like Swiss automation having to retrain their vision system, but these problems are not insurmountable.

So there are a lot of advantages to this mat for the users also in the manufacturing process. So the previous product that is no longer available would have been a backing with bristles attached. So two different materials. This one is printed all in one piece, so it's easier to manufacture. It's monolithic, it's all one material throughout. So it would also be easier to recycle in the future.

Another advantage is that OPT can print these on demand. They don't have to make excess. They don't have to do any trimming. They can just make what they need when they need it.

00:13:59:17 - 00:14:07:01

Peter Zelinski

And Swiss Automation is now using this as a one for one replacement of the mat that it used to use, the mat, that it can no longer obtain.

00:14:07:17 - 00:14:19:19

Stephanie Hendrixson

Thank you to Swiss Automation for hosting us. If you enjoyed this episode of the show, leave us a like, leave a comment below. Let us know what you enjoyed and if you're enjoying The Cool Parts Show, please consider subscribing so you get notified about all of our new episodes.

00:14:20:07 - 00:14:31:05

Peter Zelinski

If you have an idea for a cool part, even a strange niche part like this. Like we never expected to be covering 3D printed carpet. Tell us about it. CoolParts@AdditiveManufacturing.media.

Related Content

Preassembled Turbojet Engine, 3D Printed in One Build: The Cool Parts Show #75

Turbojet engines typically consist of hundreds or thousands of parts, but this engine — 2023 winner of The Cool Parts Showcase for Best Proof of Concept — was 3D printed as just two pieces, with the monolithic rotor embedded inside the stationary engine shell.

Read MoreFlexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More