Hybrid Production, Not Just Prototyping, at Matsuura's New Additive Manufacturing Center

The new Matsuura Machinery USA Lumex Additive Manufacturing Center is one part lab, one part showroom and one part production facility—all meant to showcase the company’s hybrid manufacturing capabilities.

Share

Less than five years after Matsuura Machinery USA opened its headquarters in St. Paul, Minnesota, the company has revealed a new centerpiece of this 38,000-square-foot operation: a laboratory and demonstration facility called The Matsuura Machinery USA Lumex Additive Manufacturing Center.

Matsuura Machinery Corp. of Japan, of which Matsuura Machinery USA is a subsidiary, has been involved with hybrid manufacturing—metal powder-bed selective laser sintering combined with high-speed milling—for roughly 16 years. And as the center’s name suggests, its Lumex series of hybrid machines are the focus of this facility.

Tom Houle, director of Lumex North America/Matsuura Machinery USA, explained during my recent visit to the center that the latest Lumex Avance-25 and the Lumex Avance-60, are actually the company’s fifth generation of hybrid machines—a point of pride for a hybrid technology that’s starting to gain a foothold in production-level manufacturing.

The center itself contains four Lumex Avance machines (three Avance-25s and one Avance-60), all enclosed in glass walls and situated squarely in the middle of the larger Matsuura facility. During my visit, I took a look at a test build of the Avance-25 (see the video below), the smaller of the two machines, capable of processing parts and molds up to 256 × 256 × 300 mm. After the part is designed in proprietary CAM software, which includes laser scan and milling paths as well as a simulation function, the build process begins with powder distribution—a 0.05-mm-thick layer for the standard 500-W laser, or 0.1-mm-thick for the optional 1-kW laser. Each layer is sintered and the process repeats itself for 10 layers. (This is a user-definable parameter, but 10 is the default.)

After the 10th layer is sintered, the pre-milling powder suction operation removes powder around the area about to be machined. Running at up to 45,000 rpm, the milling spindle then begins to finish the outer surface of the part with a ball end mill up to 10 mm maximum diameter. As we watch the build, Houle tells me that due to the high speed of the spindle and small cutter sizes (the automatic toolchanger carousel holds up to 20), any chips created from the milling are small enough to be carried by the gas flow into the adjacent areas of the powder bed and away from the work area. Additionally—and importantly—should a build failure occur, the software will generate a machine path and instruct the mill to machine the part back to the last known surface height before continuing the additive operations from that layer.

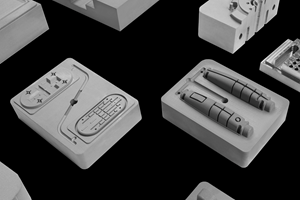

This overall process—10 layers of sintering, followed by high-speed milling, followed by 10 more layers of sintering and so on—is repeated until the part is finished. Matsuura points to its Avance series’ ability to machine internal surfaces, including complex internal geometries such as lattice structures and intricate cooling channels, that make them a natural fit for mold and die manufacturing. Indeed, most of the display items at the grand opening of the center were selected to showcase the deep ribs and integrated cooling channels made possible with hybrid manufacturing, including cores and molds for digital cameras and impact drivers. These are not prototype parts, Houle says, and these are not just prototyping machines. “That was really the focus of these fifth-generation machines—to take it from a prototyping stage to prime-time production,” he says. “We have production software, we have production machines, we have everything that we think the North American markets need to take additive and hybrid additive especially into production.”

Houle expects the new Lumex Additive Manufacturing Center to operate both as a showroom and as a development center—a place where the company will work on developing new powders and new hybrid technologies to serve its customer base. Houle also expects the center to do service bureau work for customers, as well as test cuts to prove out the hybrid process for potential customers. The center will soon have three application engineers on staff to help design and produce parts, including one engineer from Japan who will soon join the team full-time. Houle says that the company’s goals to sell hybrid machines aren’t particularly lofty this year, although he expects to exceed them.

“Customers are really deciding when to get into the hybrid AM,” he says. “It's about whether you want to have finished product. We’re in the process of doing an experiment with a customer where they've sintered and machined a component separately, and now we're doing it with hybrid as a direct comparison. Customers want to see the return on investment. I think this technology is still new enough and changing enough that to spend a million dollars at this point, people are scared. But we have cases where we are saving customers more than that every year just on a molding cycle improvement alone.”

Related Content

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read MoreComplete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More4 Ways Augmented Reality and 3D Printing Intersect

Augmented reality (AR) is bringing benefits to additive manufacturing, and vice-versa.

Read MoreRead Next

Video: The Case for Hybrid Manufacturing in Moldmaking

Instead of relying on EDM to machine features recessed deep into the part, machine those features while 3D printing progresses, finishing them before they become hard to reach.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More