Card Decks Leverage Additive Creativity

How custom card decks are helping people be more creative with AM.

Objects associated with the Design Heuristics for Additive Manufacturing cards. Photo credit: Dr. Alexandra Blösch-Paidosh and Professor Kristina Shea, Engineering Design and Computing Laboratory, ETH Zürich.

While most people don’t normally associate playing cards with being creative, there is a growing trend in the engineering design community to use custom card decks to inspire new ideas during the early stages of design. It all started about 10 years ago when a team of mechanical engineering and industrial design graduate students in the interdisciplinary Design Science program at the University of Michigan connected with faculty in psychology. Working together, the team extracted 77 strategies from thousands of different design concepts and embodied them in a set of cards called the Design Heuristics.

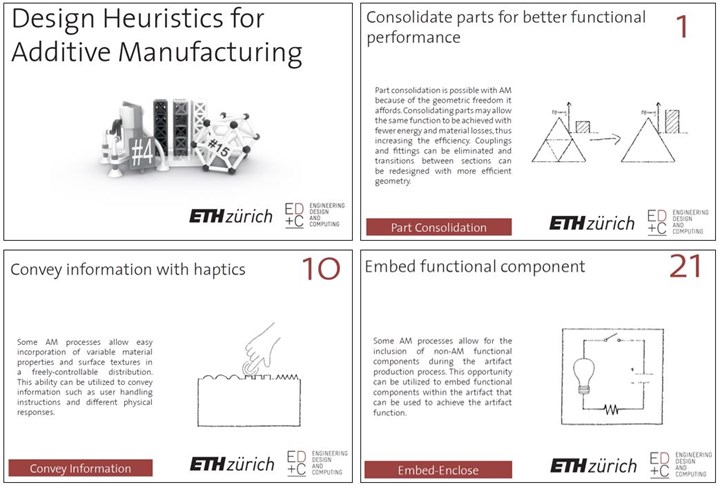

Examples of the Design Heuristics for Additive Manufacturing cards from Dr. Alexandra Blösch-Paidosh and Professor Kristina Shea, ETH Zürich (used with permission, available here).

Each card contains a brief description of one of the 77 heuristics along with an abstract image showing its application. The back of each card features two sketches showing how the heuristic is used in consumer products. The cards have been used in a variety of different engineering and design courses, and countless workshops and studies have been conducted to demonstrate their effectiveness inspiring new and creative ideas in students as well as engineering practitioners.

Fortunately for those working in Additive Manufacturing (AM), a team led by professor Kristina Shea at ETH Zurich has developed a set of design heuristics specific to AM. She and her graduate student, Alexandra Blösch-Paidosh, examined 275 AM artifacts and identified 25 heuristics that are embodied in a set of cards that define each heuristic and include a sketch and an example of how the heuristic is used. The team also created a set of 3D printable objects to demonstrate each heuristic, which is even more helpful for visualizing the power of AM. The objects are available on Thingiverse, and the Design Heuristics for Additive Manufacturing cards can be downloaded from Professor Shea’s Engineering Design and Computing Laboratory website.

Similar to the original 77 Design Heuristics cards, the Design Heuristics for AM cards (and objects) can be used to inspire creative ways to leverage the design freedoms of AM during the early phases of design. Recent studies with novice designers (i.e., students) found that the cards were more effective at generating ideas and communicating Design for AM concepts compared to a lecture alone. Given the challenges of teaching people to be creative with AM, I have found that having a set of these cards to pass around to novice AM users in industry during a workshop is an effective way to get them to think “outside of the box” when it comes to AM, and it has been helpful to follow professor Shea and her team’s research to back that up.

Another set of cards that I’ve found to be quite useful during AM brainstorming sessions is the AM Design Principles cards developed in collaboration between faculty and students at the Singapore University of Technology and Design (SUTD) and the U.S. Air Force Academy. This set of cards defines 23 design principles that relate to an AM product and its printability. While many of the AM design principles are the same as the design heuristics for AM (e.g., consolidate parts, enable customization, lightweight with lattices), the AM Design Principles cards also provide principles for transforming the design process or the associated business model with AM. For instance, one of the AM Design Principles cards suggests a “Printed Perturbation Study” whereby several variations of a design are 3D printed and evaluated to find a good design. Thanks to AM, sometimes it is just easier to print and test everything versus trying to analytically model or simulate each design. Another principle suggests “Rapid Replacement” whereby AM is used to produce replacement parts on demand. This is a good example of how AM might lead to a new business model when considering a new product that leverages AM.

The team conducted experiments with 61 students, who completed two ideation tasks – the first without the cards and the second with the cards. They found that while the number of ideas was the same in both tasks, the quality and novelty of the ideas generated using the AM Design Principle cards improved significantly. More details can be found in the team’s recent publication.

The AM Design Principles cards became central to the dissertation of Blake Perez, now at nTopology, who worked under the supervision of professor Kris Wood at SUTD. They made the cards readily available via ResearchGate, and additional studies of the cards’ effectiveness are ongoing. Meanwhile, I’m anxious to see if Blake can find a way to embed some of these principles in nTopology’s design software and really enhance people’s creativity with AM.

So if you are struggling with ways to get your team to be more creative with AM, download and give them one (or both) of these sets of cards to try. They just might contain the inspiration your team needs to find a novel way to leverage the power of AM. What have you got to lose?

Read Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More