RAPID + TCT 2022 Report: Advancing into the Next Season of Additive Manufacturing: AM Radio #18

Editors Stephanie Hendrixson, Peter Zelinski and Julia Hider share observations, insights and photos from the latest RAPID + TCT trade show.

ListenSafer Nuclear Energy: 3D Printed Silicon Carbide Fuel Forms

Binder jetting provides a way to create pure silicon carbide fuel structures that can withstand the harsh environment of a nuclear reactor and provide a strong barrier against the release of radionuclides.

Read More3 Types of 3D Printed Tooling for Injection Molding: AM Radio #16A

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

Listen3D Printing Lightweights Large Cutting Tools Used in Machining

Larger machined parts require larger, heavier cutting tools. 3D printing enables Star SU Neher to produce lightweight large tool bodies and add features that improve tool life and performance.

Read MoreAerospace Applications for 3D Printed Composites: AM Radio #15A

3D printed composites are taking the place of traditional metal parts in a specific niche of the aerospace industry.

ListenMicro 3D Printer Complements Micro Moldmaking Capabilities

For micro mold provider Accumold, the Nano Dimension 3D printer provides a way to produce micro-scale prototypes and rapid tooling.

Read MoreAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreCan Metal Parts Be Replaced With 3D Printed Composites?

High performance materials such as carbon PEEK have allowed Werco Manufacturing to 3D print parts for aircraft trainers that function like metal. But can this extend to end-use aircraft parts?

Read MoreUsing (And Scaling) FDM 3D Printing for Production

Maxwell June’s razor press, which is designed to combine the ease of use of a disposable razor with the environmental and cost benefits of a wet shaving system, is made via FDM 3D printing. How did the company make this choice, and how does it plan to scale up?

Watch3D Printing Reduces Time, Cost of Building Molds for Composites

Massivit 3D’s cast-in-motion technology uses a 3D printed gel to expedite production and lower costs associated with making molds for large, fiber-reinforced composite parts.

WatchZooming in on Micro 3D Printing: AM Radio #10A

This week on AM Radio, Peter Zelinski and Julia Hider discuss additive at the extremes, including micro 3D printing. What are the opportunities and challenges of 3D printing on a microscale?

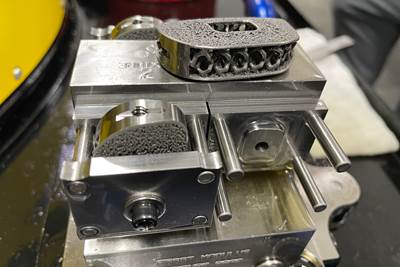

ListenMold Shop Evaluates Mantle Process for 3D Printing Steel Injection Molds

According to tests performed by Westminster Tool, Mantle’s 3D printing materials behave similarly to traditional steels and hold up well during molding, making them easy to incorporate into existing moldmaking processes.

Read More