Velo3D Develops Supplier Network to Scale Production of Sapphire XC Machine (Includes Video)

The company’s larger size machine is also the machine seeing larger demand. Successful integration of subassembly suppliers with the company’s own production in California began this year.

Share

Read Next

Laser powder bed fusion is now being applied into enough production applications that the challenge facing AM equipment producers is to make enough machines. Velo3D representatives stressed this demand when I recently visited the company’s headquarters and manufacturing operation in Fremont, California. “Our challenge now is to scale up production” is a point I heard in various forms from various people during my visit. At this site, the array of machines in various stages of assembly on the production floor gives a feel that is very much like the assembly floor of a company building other mass-produced production equipment such as CNC machine tools.

Sapphire XC machines in assembly at Velo3D’s headquarters and production facility in Fremont, California.

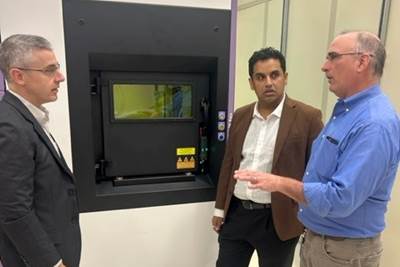

Brad Kreger, executive VP of operations, oversees this machine production. He describes one significant advance the company has made in response to the need to scale. To expand capacity, the company has developed a supplier network and has now begun outsourcing critical subassemblies, such as the upper transfer assembly seen in the video above. “In the first quarter of this year, we did our first uncrating of a subassembly delivered from a supplier and incorporated into a production machine,” he says.

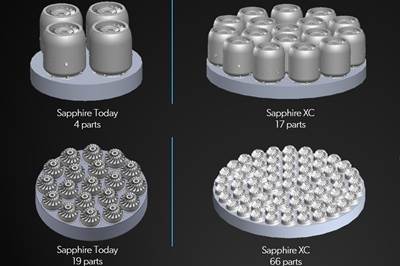

The company’s bigger machine model is also its bigger seller. Its larger capacity Sapphire XC laser powder bed fusion machine — that is, larger than the original Sapphire machine — offers a build surface 600 mm in diameter (big enough for a superhero’s shield) and a build height of 550 or 1,000 mm. Spacecraft engine components represent one production application of the machine. At present, the company is able to build up to 10 of these machines per quarter alongside building the smaller machines. Total lead time for an XC machine to complete its production process is around 50 days, but only 20 days is the machine assembly. The rest is dialing in machine parameters to sufficient precision to ensure interchangeable performance from machine to machine, he says.

Brad Kreger (right) says outsourcing subassemblies like the upper transfer assembly seen here has entailed documenting and systemizing the company’s assembly procedures.

The interchangeability is partly what has enabled the demand for the larger machine, the company says. Software and sensing within the printer combined with tuning of the machines for production means that a build program can run equally well, without modification, on either the Sapphire machine or the Sapphire XC. Production proven out on the smaller, less expensive machine can therefore be directly transferred to the XC as the user shifts to this machine for greater capacity.

A similar, parallel shift is happening in Velo3D’s machine production. Indeed, in a way, the company is also encountering a similar need for interchangeable process control. When machines were built entirely in-house, “We used to manufacture to drawings,” Kreger says. Among a team within a single facility, there was a shared understanding of what the assembly drawing requirements meant and how to work to them. “But what is intuitive to one group is not intuitive to someone else,” he says. Outsourcing of subassemblies therefore meant developing clear instructions derived from the assembly drawings. Success at the outsourcing to a large extent came from this effort — meaning that, in this context too, repeatable production required a system that could operate the same way in two different places.

Related Content

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

Read MoreVideo: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreVideo: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

Read MoreRead Next

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreLarge-Format Metal 3D Printer Will Let Users Keep the "Recipe" But Gain Productivity

The forthcoming Sapphire XC metal powder bed fusion system from Velo3D adds size and speed, but requires no new process development for existing part designs.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More