Velo3D Debuts 8-Laser Machine for Parts This Size and Bigger

Sapphire system scales up — see the new machine along with examples of large metal parts 3D printed in one piece.

For powder-bed additive manufacturing machines, size opens the way to productivity. A larger build volume offers the chance to produce an increased quantity of parts efficiently by grouping more of them into the build. However, another advantage of size is … size! Bigger parts can be made in one piece through AM thanks to bigger machines.

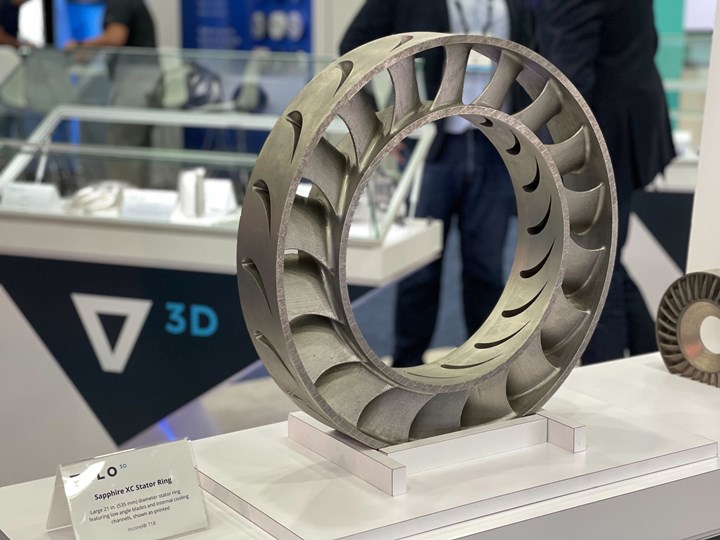

This part is an example. The 21-inch-diameter Inconel 718 stator ring with internal cooling channels was made on Velo3D’s Sapphire XC. This metal AM system is capable of producing parts 600 mm in diameter by 550 mm in height, and also features 8 lasers for high throughput. The Sapphire XC system, the first unit of which shipped to SpaceX in December 2021, is making its public debut in Velo3D’s booth at IMTS in 2022.

Like previous Sapphire machines, the new larger model includes control features aimed at minimizing the need for support structures. The stator blade illustrates this. Its low-angle blades were printed without supports despite the overhang they presented during printing. Other never-before-seen parts in the Velo3D booth were also made on the new Sapphire XC.

This 21-inch Inconel stator ring was produced on new larger-size Sapphire powder bed fusion machine. Photo Credit: Velo3D

Related Content

-

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

-

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

-

This Year I Have Seen a Lot of AM for the Military — What Is Going On?

Audience members have similar questions. What is the Department of Defense’s interest in making hardware via 3D printing over conventional methods? Here are three manufacturing concerns that are particular to the military.