Taking Advanced Manufacturing Technology to the Site of Repair

The cost of a broken or malfunctioning part extends beyond monetary figures. Siemens Energy’s Additive Manufacturing Onsite Repair (ADDMORE) service aims to promote shorter repair times, longer intervals between service and increased availability of machines and spare parts.

Investment follows a vision and is based on a business case, thus the pressure is on for owners to maximize their machines’ life and reliability. Of course, downtime can be kept to a minimum through innovative predictive maintenance strategies. But do you have a solution when disruption occurs and the forecast is at risk?

It is crucial to a business’s profitability that repairs are conducted rapidly and assets are put back into service as soon as possible. In the event of a breakdown or repair, traditionally, an affected part would be removed and sent back to the manufacturer for repair. In the case of turbines, for example, one can weigh hundreds of tons, which means sending to the manufacturer is a complex and time-consuming operation. Avoiding that logistical nightmare and the inevitable delays is the concept behind Siemens Energy's portfolio of onsite services. These range from advanced, non-destructive testing using mechanized systems for eddy current inspection (ET), phased array ultrasonic inspection (PAUT), material investigation by replica technique, small specimen investigation by small punch test and mobile machining robots. However, some of the company’s more innovative solutions include mechanized cladding systems, in-situ coatings and micro laser welding, as well as the robotic additive manufacturing (AM) solution Siemens Energy refers to as “printing out of the box.”

Additive Manufacturing and On-Site Machining

Siemens Energy’s Additive Manufacturing Onsite Repair service, or ADDMORE, delivers advanced manufacturing technology usually available at a manufacturer's workshop directly to a power plant. This service is crucial for operators to get plants back into operation as quickly as possible.

By building layer-by-layer, additive manufacturing offers enormous flexibility in shaping. Siemens Energy utilizes various AM processes in its onsite services, including wire arc additive manufacturing (WAAM). AM is particularly suitable for power plant components such as rotors, casings and stator parts because it can build up close to the final contour. Machining then delivers the high-precision functional dimensions.

Siemens Energy’s onsite machining aims to promote shorter repair times, lower costs, longer intervals between service and increased availability of machines and spare parts. It is intended to save valuable time for transport. When spare parts are not available, or it is crucial to restore the original condition of a component, the onsite repair solution is the key.

Laser Metal Deposition

Laser metal deposition offers greater quality and precision than other types of welding processes.

Photo Credit: Siemens Energy

Siemens Energy’s laser cladding technology is also used to apply material to components that need repair.

Photo Credit: Siemens Energy

Especially helpful for part protection and repair are mechanized laser cladding, micro laser welding, cold spray coating and laser metal deposition, in which metallic powder or wire layers can be applied to any component. Compared to other welding processes, laser metal deposition’s quality and precision are exceptionally high, as is its scope of materials, which includes some that typically cannot be welded. This technology is mainly used to repair parts, but it also optimizes protection against corrosion and wear.

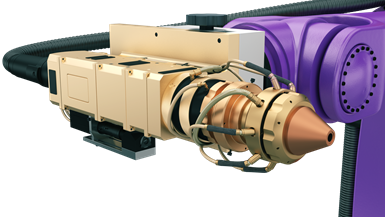

Alongside traditional welding technology, Siemens Energy’s “3D printing out of the box” uses mobile robotics systems for additive refurbishment options, allowing small and large components to be repaired onsite. This system is comprised of a robot, powder laser equipment and a control system. The cell is transported to a site, assembled along with a mobile laser protection system, calibrated and is ready to start work within a short time.

By utilizing an automized robot laser system application, the speed and accuracy of the material application can be significantly improved as it has the flexibility to cope with nearly all geometries and dimensions.

Three Scenarios for Onsite Repair

Siemens Energy’s onsite repair can facilitate three essential services: rotor journal repair, component repair and rotor refurbishment. The individual components of rotating equipment are crucial for reliable and efficient operation. However, any unacceptable wear on these components can affect the safety and efficiency of operation.

When restoring the original journal diameters without a bearing shell exchange, the ADDMORE technique enables the rectification of scoring marks or damages without a journal exchange. The repair is intended to restore the original journal diameters to ensure optimal operation. For a successful repair, it is crucial to precisely meet the tolerances for diameters, all other geometric dimensions, and all requirements in regard to metallurgical properties — all accompanied by several NDT methods.

Onsite rotor refurbishment is considered the ideal solution when repair is carried out without exchanging the entire rotor. The original diameters can potentially be kept for gas turbines, steam turbines or generator rotors. The exact tolerances for diameter and other geometric dimensions are met, and all requirements for surface and material quality are fulfilled. In addition, material properties, such as hardness, are retained. Customers can save valuable time and money.

Taking ADDMORE to Turkey

One recent application of this solution came from a power plant operator in Turkey. The onsite repair team carried out refurbishment for gas turbine components, restoring parts for the turbine where increased wear was detected during scheduled and unscheduled outages.

The component needed to be exchanged or repaired ahead of its originally expected life. For this weld repair, any distortion would have been unacceptable. This refurbishment was completed in less than five days on the critical path, considerably quicker than if the part needed to be sent back to the factory, with the total repair costing a third of replacing the part.

By utilizing the ADDMORE service, operators can save significant costs and time. However, as each case is unique, exactly how much differs from case to case. Again, there are numerous variables for the time, and the downtime depends on the availability of a replacement part. If the spare parts were in stock and could be sent directly to the customer's site, the downtime would be similar. However, if the spare part is unavailable, the lead time could be several months.

Looking beyond the cost and time savings, the ADDMORE onsite refurbishment strategy has another advantage in its approach to materials. ADDMORE offers the opportunity to enhance part performance by utilizing higher alloyed metals in repairs. These higher alloyed materials have better resistance to erosion and oxidation. Additionally, the materials chosen are based on components’ engineering, operational or design requirements. So, a root cause analysis before a repair can ensure that the individual operational experience, installation measures and performance enhancement of the component are taken into consideration.

Mirko Düsel, SVP Generation Service, Siemens Energy

Related Content

ConocoPhillips Sees Oil and Gas Supply Chain Opportunity With Additive Manufacturing

Production of parts when needed and where needed can respond to the oil and gas sector’s multibillion-dollar challenge of holding parts in inventory. The supply chain benefit will justify additive even before the design freedoms are explored.

Read MoreUPM Additive Solutions and Authentise Develop Vendor Managed Inventory Solution for Additive Manufacturing

The Vendor Managed Inventory (VMI) solution for additive manufacturing streamlines inventory management, ensuring that critical materials are always available and minimizing the need for manual intervention.

Read MoreHitachi Rail Uses Roboze Technology to Produce Spare Parts

Using Roboze’s ARGO 500 3D printer enables Hitachi Rail to implement industrial 3D printing technology, using materials such as Ultem 9085 and Carbon PEEK for the production of spare parts for its trains.

Read MoreHow a DOD-Funded Resilient Manufacturing Ecosystem (RME) Is Coming Together at Neighborhood 91

Pittsburgh’s additive manufacturing campus doubles as a test bed for a Department of Defense project aimed at developing a reproducible ecosystem for on-demand production of critical parts.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More