Simulation and Updates for Hybrid Manufacturing

DMG MORI continues to improve its Lasertec 65 3D hybrid machining center, and has a new hybrid machine in the works.

Share

Read Next

One of the machines on display at DMG MORI’s Pfronten, Germany, open house this past January was its Lasertec 65 3D, a hybrid five-axis machining center that is equipped with a laser additive head. This machine tool is based on the company’s MonoBlock machining center design and uses a laser deposition process to build up parts additively, outside of a powder bed environment. A 2.5-kW diode laser melts the metal powder as it is dispensed, while argon gas provides a shield against oxidation.

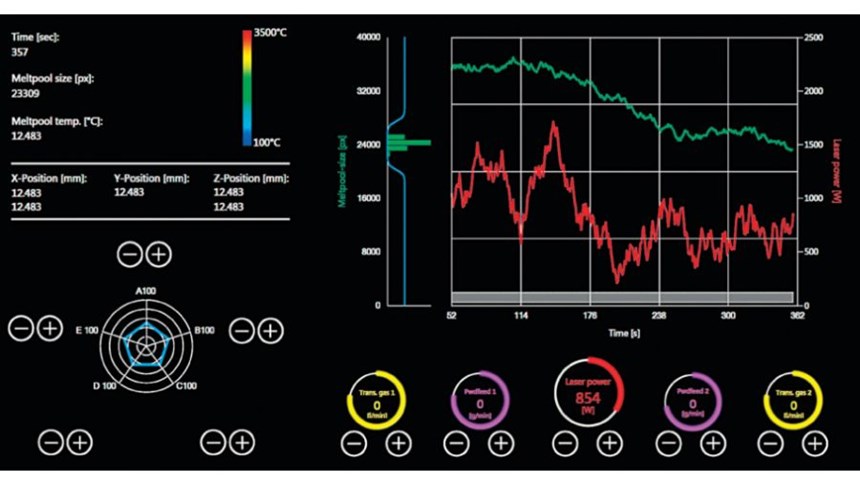

While the Lasertec 65 3D has been on the market for some time, DMG MORI emphasized several recent updates to the system during the event. Foremost among these is the addition of melt pool monitoring technology, making the machine a closed-loop system. The hybrid machine is now equipped with AMAnalyser, a system that tracks melt pool temperature and size, laser power, and argon levels, among other details, in real time. This information can be displayed on the control as shown in the second image above. But beyond simply recording this data, the system can also make adjustments to keep the build within specified tolerances. This capability makes it possible to run the machine unattended while maintaining required surface finish and porosity.

Other improvements to the machining center’s additive manufacturing capabilities include:

- Support for multiple materials. Dual hoppers enable switching the additive head between two different materials. Because the powder is blown into the laser beam (rather than held in a bed) no cleanup is required before such a change.

- Multiple nozzles. The machine is now available with a 1.6- or 3-mm powder spray nozzle. The width of the nozzle determines the minimum width of the path and wall thickness; offering two options provides greater flexibility.

- Programming capabilities. DMG MORI provides specialized CAD/CAM software to support hybrid manufacturing, including independent postprocessors for subtractive and additive manufacturing.

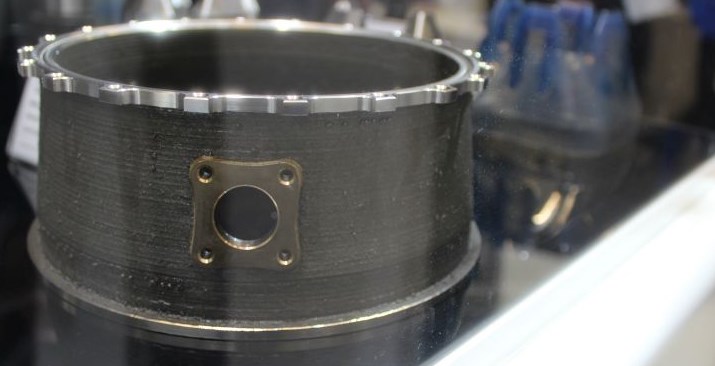

Uses for this machine include the manufacture of aerospace components, repair of damaged parts, and application of 3D coatings. One sample part on display was a scaled-down version of an aerospace turbine casing (see the third image above) that illustrates the machine’s capability to build in two different materials. The main body of the part was built up from Inconel 718 powder, but the flanges on the side were added in bronze afterward. Dual powder hoppers enabled automatically switching from one material to the next. The outer wall of the part is 5 mm thick and built via two passes of the 3-mm nozzle. The cycle time on this part was just under 7 hours.

Though not on display during the open house, DMG MORI is also developing a second hybrid machine. The forthcoming Lasertec 4300 3D is based on a turn-mill machine so that turning will be possible in addition to five-axis milling and additive manufacturing. The hybrid will be equipped with as many as five powder deposition heads, and is expected to premier later this year.

Related Content

-

UMaine’s FoF 1.0 Large-Scale 3D Printer Shatters Former Guinness World Record for Additive Manufacturing

The large-scale thermoplastic polymer printer offers new opportunities for eco-friendly and cost-effective manufacturing for numerous industries, including national security, affordable housing, bridge construction, ocean and wind energy technologies, and maritime vessel fabrication.

-

Nicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

-

Hybrid Additive Manufacturing Improves Debarking Knife Tip Strength and Production Efficiency

Nicholson Manufacturing chose the Mastercam APlus specialized add-on to unlock hybrid manufacturing for making its debarker knife tips, enabling it to add durable layers to the wear surfaces of the tips to make them more resilient while also making the production process more efficient.

.jpg;width=70;height=70;mode=crop)