When Sintavia founder and CEO Brian Neff first saw a 3D printer fusing powder into metal parts in 2011, the possibilities struck him almost immediately. The geometric complexity that this technology could achieve was clear, but what was perhaps most salient in that moment was how additive manufacturing (AM) represented a pivot away from forgings and castings, and the need to machine away large amounts of material to achieve a final part geometry. Additive manufacturing, Neff saw, would be a way to deliver small metal aerospace components more quickly and flexibly, and with far less waste. A business founded on AM, he posited, could be both commercially successful and less wasteful than conventional manufacturing.

In 2015 he launched Sintavia, an aerospace manufacturer that would be dedicated to producing complex metal components using only this technology. The company today has achieved something very close to that vision, operating nearly 30 metal powder bed fusion (PBF) 3D printers at a 55,000-square-foot facility in Hollywood, Florida. (The building itself offers an interesting look at how AM reshapes manufacturing facilities — more here.) Its goals and work have shifted somewhat in light of discovering the best applications of production AM, and so too has the thinking around sustainability evolved.

At the outset, “We felt what we were doing was less wasteful than traditional manufacturing,” Neff says, “but we didn’t have a good way to know that.” Now, the ways of knowing are becoming clearer. Sintavia has become more efficient at identifying when a particular application is a good fit for both sustainability and additive production, Neff says, but success at one adds challenge to the other. Reaching its current level of production with 3D printing is exposing the less obvious aspects of the additive process that will need to be addressed to achieve true — and scalable — sustainable manufacturing.

3D printing certainly looks less wasteful than conventional manufacturing processes, but is it really more sustainable? At a production scale like Sintavia’s, this question becomes an important one to answer. Photo Credit: Sintavia

Digging Deeper into Sustainable Manufacturing

At a glance the additive process does look less wasteful than conventional metalworking by virtue of applying material rather than taking it away. And most companies using metal PBF reuse the unmelted powder in future batches, another fact that suggests a less wasteful manufacturing process. But at a production scale like Sintavia's, other questions regarding the sustainability of AM start to emerge: How much energy are the machines consuming? What end product designs justify running that equipment? What is the best use for the small amount of waste the process does generate?

Sintavia is on its way to discovering the answers to these questions. In November of 2019, the company helped launch and became a founding member of the Additive Manufacturing Green Trade Association (AMGTA). Led by Sherry Handel, the organization is co-located in Sintavia’s South Florida facility and now has more than two dozen member companies.

The AMGTA is an independent nonprofit that doesn’t serve Sintavia alone, but parts of its research have been informed and supported by virtue of being so closely situated. The organization’s investigations so far have focused on the carbon footprint and cost potential of AM in aircraft systems; the state of knowledge on environmental impacts for metal AM; disposal procedures for powder condensate; and gas solutions for sustainable metal additive manufacturing.

No manufacturing method can be declared sustainable or not sustainable without considering the entire lifecycle assessment.

Underpinning its work, though, is the principle Neff has been concerned with since those early days: The fact that no manufacturing method can be declared sustainable or not sustainable without considering the entire lifecycle assessment. While it may be easy to say, We print with our unused powder, or Our parts go into energy efficient aircraft, these isolated statements at worst could be called greenwashing, and at best do not qualify a part or process as sustainable. Instead, as the leadership of Sintavia and AMGTA would argue, it is necessary to consider the full chain from material extraction and manufacturing through product lifecycle to accurately make such an assessment.

How does this play out, then, at an aerospace manufacturer? Sintavia has already learned and is putting into practice some lessons both to make its own business more sustainable and to support a greener world. Here are three:

1. Reconsider part design.

“The idea behind Sintavia was to print smaller commercial aerospace parts,” Neff says, but this turns out not to be the best-case scenario either for additive manufacturing or for sustainability. Instead, he says, the greatest wins in both cases come from the 3D printing of larger and more complex mechanical systems and components. Metal additive manufacturing cannot compete on cost for a simple bracket that could be easily machined, but it can if that bracket is part of a multi-piece assembly that can be consolidated into just one printed part. Similarly, changing production to 3D printing for a simple part is unlikely to result in significant weight savings or the efficiency gains that might make an aircraft more sustainable to operate, but redesigning a complete assembly offers these opportunities.

“Making spoons this way would be wasteful — there’s no way for additive manufacturing to win out over traditional stamping in terms of embodied energy,” Neff says. “But an entire rocket engine? That’s a better proposition. The more you go up the complexity curve, the better and more sustainable it is.”

2. Identify and learn to deal with waste streams.

Metal 3D printing via PBF is a more circular process than subtractive manufacturing, as much of the time unmelted powder can be reused as feedstock. And by virtue of working from near-net shape prints, the process generates less in the way of machining chips during postprocessing. Yet there are other sources of waste that only become obvious at production-scale AM. One is condensate, particles of metal that are evaporated during printing and then condense and get collected in a machine’s filters. Today this material must be inerted with sand or mineral oil and disposed of as hazardous waste. But at Sintavia’s scale, the condensate began to build up to the point that it became significant as a waste stream. The company has now developed a process by which some of this material can now be recycled, and has published a white paper on the topic in partnership with the AMGTA and Triumvirate Environmental.

3. Rethink end markets.

While conventional aircraft make up a large portion of the customers that Sintavia serves, the company is also thinking beyond this and producing parts for “New Space” applications and defense applications as well as next-generation aerospace. “Electric flight will be totally enabled by additive manufacturing. To fly electric aircraft commercially, you need 3D printing,” Neff says, pointing to complex parts such as small, perfectly aligned copper coils these aircraft will need. The geometries are difficult to manufacture conventionally, yet could be simple to achieve additively. Future lighter weight, electric or hybrid planes will mean a move away from the use of jet fuel and the emissions it creates, as well as aircraft that are more efficient to operate overall. These new products are the space where Sintavia and additive manufacturing can perhaps make the most impact, both in terms of real manufacturing change and sustainability.

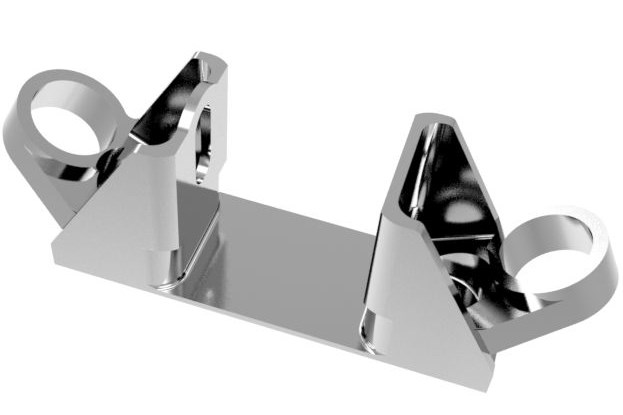

This last point — that what you make matters, not just how — is illustrated in a TEDx talk Neff delivered at the end of 2019. In the presentation he uses the example of a bracket found on the Boeing 767. Twelve such brackets are found on the back of each engine. Today, made conventionally, the parts carry too much material, with excess wall thickness and wide corners.

The original bracket made conventionally. Photo Credit: Sintavia

As a case study of what might be possible, Sintavia optimized the bracket design for light weight and 3D printability. The redesigned bracket is 50% more durable than the original and 20% lighter. In another application this weight savings might not have much impact on the overall function or efficiency of a system, but in aerospace it can bring significant advantages. The company found that by dropping just 30 grams from each of these parts, it would be possible to save 720 gallons of fuel per year on an aircraft equipped with the new design.

The redesigned, 3D printed bracket is 20% lighter, potentially translating into hundreds of gallons of fuel savings per aircraft per year. Photo Credit: Sintavia

Ultimately, Neff hopes to see the advantages of metal 3D printing applied not just to improve existing aircraft and systems, but as a way of enabling the new age of aerospace and beyond. Additive may not be a one-size-fits-all solution to sustainable manufacturing, but when applied in the context of a total lifecycle assessment, OEMs and their suppliers can be more certain about the status of whatever they are making and how they produce it.

“Additive manufacturing inspires and seizes people,” Neff says. With due diligence around the material, design, process and product, that inspiration can be founded in the certainty of driving toward a greener future both for manufacturing and the world at large.

Related Content

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreWith Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreRead Next

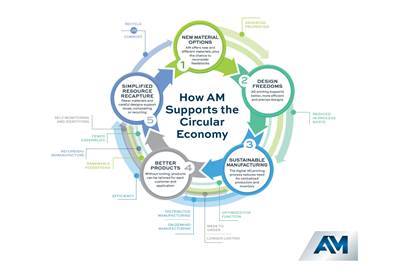

Infographic: How Additive Manufacturing Supports the Circular Economy

This downloadable infographic illustrates how 3D printing can be applied for more sustainable manufacturing through every stage: Material, Design, Manufacturing, Product and End-of-Life.

Read MoreAdditive Manufacturing Will Aid And Accelerate The Circular Economy

A circular economy links material, design, manufacturing, product and end-of-life in a continuous, sustainable loop. This special report illustrates the roles for 3D printing every step of the way.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More

.jpg;width=70;height=70;mode=crop)