Reimagining Implants

A medical-industry contract manufacturer that built its reputation on CNC machining is now helping its customers realize the advantages of additive manufacturing.

Share

Read Next

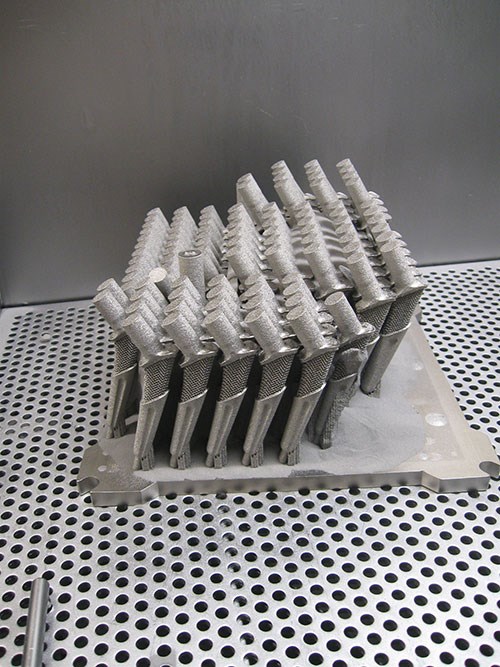

Ronald Dunn, vice president of medical-industry contract manufacturer DiSanto Technology, says the photo on this page illustrates the future of spinal cage implants.

The part shown is actually a scaled-up model DiSanto uses to illustrate this design to medical device companies. Surgeons and other medical-industry professionals who are knowledgeable about spinal surgery look at this model and immediately appreciate the benefit: bone ingrowth.

A spinal cage implant essentially serves as a spacer between adjacent vertebrae that are fused together during spinal surgery. The part is usually machined, whether from a plastic (PEEK) or from a titanium alloy. Because it is machined, the part is typically dense and solid.

This new design is self-evidently better, Dunn says. Because the part’s mesh allows the patient’s bone to grow into it, the body accepts this implant such that the fit improves over time. Few would contest the value of this ingrowth, he says. It’s just that machining has never offered a way to create this mesh geometry. The mesh seen here was possible because this part, instead of being machined, was produced through additive manufacturing. The part was grown in successive layers on an electron beam melting (EBM) machine from Arcam.

DiSanto now has two of these machines, along with one Arcam employee on-site, as part of a partnership with Arcam aimed at increasing both the demand and the capacity for additive manufacturing of medical parts in the United States. DiSanto sees so much potential in this method of manufacturing that the company is building an expansion so it can add four more Arcam machines.

Historically, DiSanto has been a machining business. About 55 CNC machine tools run at its Shelton, Conn., site. Dunn says additive manufacturing will expand the use of these machines. That’s because practically every additively produced medical part needs machining of critical features as a secondary step, he says. Plus, many implants produced additively need complementary machined components that are part of the surgery.

However, additive manufacturing will also change which parts the company machines, Dunn says. Certain components being machined today will be produced additively instead, after they are redesigned into more functional forms that can only be produced through additive manufacturing.

The spinal cage is an example. DiSanto has long made these cages through machining, and continues to do so, but company engineers saw how additive manufacturing could create a better design. The company produced the prototype at its own expense so it could pitch the idea to customers. Going forward, Dunn expects to win work for additive manufacturing by taking this same initiative with other parts that are currently made through machining. The company’s machine shop has thus become its prospecting field.

Supplier Challenges

The partnership with Arcam works this way, says Dunn: The additive machine maker gives DiSanto a measure of exclusivity in pioneering the market in the United States for manufacturing implants through EBM. Meanwhile, Arcam gets DiSanto’s commitment to the technology. From Arcam’s perspective, DiSanto is the ideal size, Dunn says. His company is big enough to be a player in implant manufacturing, but small enough that it was willing to reinvent itself in pursuit of the promise of additive production.

The opportunity to make this change came at the right time. DiSanto was facing challenges with multiple suppliers that additive manufacturing neatly addressed. One involved the porous surface for bone integration on implants. Historically, this surface has been added through plasma spray coating. DiSanto’s source for that coating had recently been purchased by a competitor.

Meanwhile, DiSanto’s supplier for castings had begun to demand aggressive 15-day payment terms. “Manufacturing is all about cash flow,” Dunn says.

Additive manufacturing provided welcome relief in both situations. The additive process makes plasma spray unnecessary, because the 3D printed part can have the porous layer just printed into the design. Also, additive manufacturing makes casting unnecessary, since this part-generating technology is essentially a foundry in a box.

Dunn says, “They say additive manufacturing machines are expensive, but I don’t see it. The cost of these machines is easy for us to balance against the supplier-related costs we no longer have to pay.”

The supreme example of this might be the elimination of forgings. An implanted titanium hip stem might come in 20 different sizes, requiring 20 different forging tools at more than $7,000 per tool. With additive manufacturing, all of that tooling expense is gone. In fact, representatives of the 20 different part numbers can all be built within the same cycle, as needed, simply by nesting the different parts within a single EBM build. The time savings in this are considerable. Owing to the need for forging tooling, a newly designed hip stem in the past would have required a lead time of at least eight weeks, but with additive manufacturing, that same newly designed hip stem can be manufactured within 48 hours.

Efficiencies such as these are sufficient to justify additive production, Dunn says. However, these savings are just the beginning. The still-greater benefit to DiSanto’s customers is the design freedom additive manufacturing gives them. They can now design their own precisely controlled bone integration geometry instead of just accepting the random surface geometry of a plasma spray. This is huge. Then there is the most important benefit of all: An additive-manufactured implant is likely to function better within the patient’s body.

The reason for this also relates to dimensional control. Plasma spray is such an imprecise process that bone reamers in surgery are oversized because of it, Dunn explains. The reamer produces an oversized cavity in the bone to accommodate the uncertain dimensions of the sprayed part. By contrast, with additive manufacturing providing control over geometry, the reamer can now be right-sized. The implant can therefore press-fit into the bone. Surface contact between implant and bone is extensive, rather than merely occurring at a few high points of the spray. As a result, the bone integrates with the implant that much more quickly.

Machining Changes

The savings in CNC machining are also significant, Dunn says. While it’s true that an EBM surgical implant almost always needs machining, that machining is slight because the part is near-net-shape—much nearer to net shape than casting or forging. As a result, all of the machining passes on an additive part are inherently finishing cuts. The costs related to roughing—including time, material and tooling—no longer have to be paid.

In addition, this finish machining tends to consist of relatively simple cuts. A part such as a hip stem has historically been produced through complex five-axis machining, but Dunn says he expects DiSanto to rely on five-axis machining much less in the future. Geometrically complex features can be produced more easily through EBM, he says, and additive manufacturing can also be used to give the part extra features that make the remaining machining easy. The hip stem might be generated with a boss for a vise to hold during milling, for example, with this sacrificial feature cut away when machining is done.

Yet in spite of these savings, the machining activity at DiSanto is likely to grow with additive manufacturing, he says. The reason is not just because additive parts need to be machined, but also because they create the need for other machined parts. An aspect of DiSanto’s machining activity that might be surprising to an outsider is the extent to which the shop machines plastic. Implants such as hip stems and knees are metal, but implants often come with plastic components that are part of the implant’s operation. Knee implants, for example, come with plastic liners that essentially serve as cartilage. Through various workholding and toolpath techniques, DiSanto has become proficient at quickly producing these non-metal parts. As additive manufacturing expands the number and variety of metal implants DiSanto produces, Dunn expects his company to have even more opportunity to apply its expertise at machining these related plastic components.

Related Content

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read More3D Printed PEEK Spine Implants in Production: The Cool Parts Show Bonus

Curiteva is using Fused Strand Deposition to produce two different lines of FDA-cleared spine implants. We visited the company’s Huntsville, Alabama, facility to learn more.

Read MoreMicro Robot Gripper 3D Printed All at Once, No Assembly Required: The Cool Parts Show #59

Fine control over laser powder bed fusion achieves precise spacing between adjoining moving surfaces. The Cool Parts Show looks at micro 3D printing of metal for moving components made in one piece.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More