“Attacks on data are a clear and present danger,” says Jim Regenor of VeriTX. “We have to approach it with our eyes wide open.”

Those attacks take many forms including the phishing and ransomware attacks most of us are aware of as we check our email each day. But more troubling are the less visible infiltrations: tactics like “steal now, decrypt later” where bad actors acquire information with plans to hack it later, or data manipulation where critical information is altered.

As a digital manufacturing process, additive manufacturing is vulnerable to these attacks. Part designs, in particular, are at risk of data manipulation. A few undetected tweaks to an STL file could result in catastrophic failure of a critical component like the propeller of a drone — or a component of a craft carrying people.

But digital data can also be protected through digital means. That’s what VeriTX is now offering by virtue of its Fortis product, a “data assurance as a service” platform that uses blockchain technology to ensure data integrity, whether that data is kept in house or sent across the world for manufacturing.

Data Assurance for STLs and More

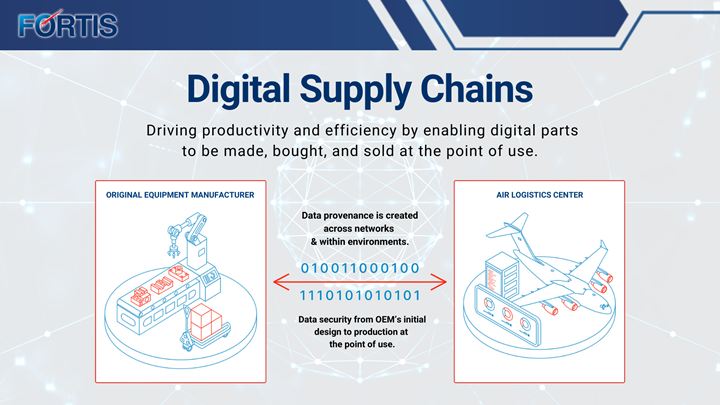

Fortis grew from the initial idea of a digital marketplace (which we covered in 2020), in which OEMs could tap into a network of potential manufacturing partners without exposing their IP to theft or manipulation. Such a marketplace could still be in the cards, but in the meantime VeriTX has found that establishing the trust necessary to make it work required stepping back up the supply chain. Before OEMs can be expected to participate in an exchange of data, they must first become habituated to protecting their data in a way that would make this possible.

Under Fortis, the focus is now on data assurance which Regenor defines as “the practice of proving data is unmanipulated, and remains in its intended state.” Compared to cybersecurity measures that focus on establishing perimeters and protections around processes and procedures, Fortis protects individual files from theft or tampering. “Cybersecurity alone is like a chainlink fence — it’ll keep out the big stuff,” Regenor says. “Data assurance deals with little things. It’s the ones and zeroes.”

Through Fortis, OEMs can protect their original designs even while sharing them with manufacturers or service providers. Image Credit: VeriTX

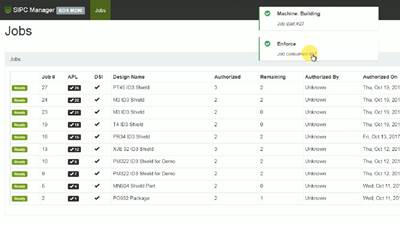

The Fortis platform offers two modes: Data Monitoring and Data Transfer, “for data at rest and data in motion,” respectively, Regenor says. In both cases the service encrypts the contents of an STL (or other) file in binary and secures it with a blockchain ledger, a recordkeeping device that travels with the data the same way that blockchain is used to protect cryptocurrency and NFTs. The ledger serves as a record of both the file’s provenance and any changes that might occur within it. And the ledger is sensitive to those changes — a tweak as small as changing the hue of a single pixel in an image file (which would change its encrypted code) would be detected with this system. The sensitivity is an obvious advantage against nefarious alterations, but it also has benefits for detecting non-malicious changes like an accidental edit to a design, or alerting a user they are working with an old file version.

For file transfer applications, both parties will be notified of any change; users can offer explanations for intentional changes, or if not intended, be alerted that the file has been altered and avoid using it. Recipients also always have the right to refuse files; anything that is unexpected or seems suspicious can be cordoned off in a quarantine.

In both cases, users need a digital ID to access the files and have to be designated within the prescribed workflow for the part. While the focus currently is on protecting the intended production files, VeriTX sees future opportunities to incorporate other types of information about parts, such as inspection data. In-printer telemetry could be used to tie quality information from the build back to the blockchain, even making it possible to skip a separate inspection step after printing.

VeriTX has three early Fortis users still to be announced, but the cross-section highlights the market segments the company hopes to serve initially. One is a provider of 3D scans that needs to both protect an existing library of scans and securely send data to partners that provide 3D printing services. Another is an advanced manufacturer serving governmental agencies, and the third is a 3D printer supplier. Although the product is aimed at additive manufacturing applications currently, Fortis could also be applied to other methods of production. Any digital information could be encrypted and protected with the system.

Microeconomic Impacts

Oftentimes measures surrounding data security can seem reactionary, a defensive measure to be taken against potential attacks. Data assurance tools are indeed a preemptive defense mechanism, but Regenor sees hopeful possibilities in their expanding adoption, too.

One of those possibilities is easing the process of auditing. Certified suppliers for industries such as aerospace and defense must invest time and money into ongoing audits to maintain that certification. Implementing data assurance tools can help OEMs have better insight into what suppliers are producing and how, potentially leading to a less onerous auditing process. “There are microeconomic savings that can be realized by reducing the time and money needed to establish that trust,” Regenor says.

Logistics is another potential area of benefit. With a secure way to protect and move information, it may become easier and more attractive for OEMs to shift spare parts to digital inventory that a supplier can manufacture on demand.

“You can push the cost of production downstream,” Regenor says, which could ultimately improve the margins on many such replacement products. Manufacturers that might initially take advantage of data assurance measures for the cost benefits of replacement part production might then be motivated to adopt such measures more broadly. “If you create value, you may get people to modify their behavior.”

Related Content

How Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreRead Next

Will Control Over Part Data Expand and Simplify AM Supply Chains?

Digital rights management for manufactured part files will enable OEMs to enforce manufacturing requirements at a distance, potentially providing an alternative to closely held relationships with suppliers of critical AM parts.

Read MoreWhere Blockchain and 3D Printing Converge, Distributed Manufacturing Can Thrive

Decentralizing production through additive manufacturing can bring numerous benefits, but these can only be realized through trust. VeriTX is building a platform to secure a trusted digital supply chain for aerospace and beyond.

Read MoreHow Additive Manufacturing Can Benefit from Blockchain: AM Radio #15B

Blockchain technology isn’t only suitable for protecting cryptocurrency and NFTs. This week’s episode of the AM Radio podcast looks at how blockchain is being applied to 3D printable files today, and how far this pairing could go.

Read More

.jpg;width=70;height=70;mode=crop)