Optimizing the Additive Manufacturing Workflow with PLM

Product lifecycle management (PLM) plays an essential role when adopting additive manufacturing within mainstream production.

Share

Read Next

When asked what type of assistance best fits their additive manufacturing (AM) needs, half of the attendees polled during a recent webinar answered that they need help with product lifecycle management (PLM). What does this have to do with AM? Plenty, especially as the focus on designing for AM and bringing AM into the production environment continues.

When AM was primarily used for producing models, prototypes and one-off parts made of nonproduction-ready materials, governance of enterprise solutions like PLM was not necessary. But with advances in materials, machines and software for AM, along with demand for parts in lower volumes, AM is becoming a production process. To fully implement an AM part and process, information must be integrated with the digital thread, and that means managing data.

The digital thread can be understood as a high-level description of what PLM does, connecting all the digital information (files, meta data, documents, etc.) throughout the product’s lifecycle, from ideation, simulation, optimization and validation, all the way through to printing, cooling and postprocessing. James White, CIMdata’s director of AM Practice, says that “unfortunately, many companies involved in AM do not consider this. Instead, they see an AM machine as just a piece of production equipment, like a molding machine, meaning they see it as an isolated silo.”

This approach is risky. Few companies are even considering PLM to manage AM data and its workflows. While some respondents to a live poll said they use Windows folders, most reported using nothing to manage their AM part data today—not PLM, not product data management (PDM) and not enterprise resource planning (ERP).

“Remember, PLM is a business strategy, not a software tool, and design for additive manufacturing (DFAM) falls under PLM.”

A Department of Homeland Security assessment shows that manufacturing made up a sizeable portion of the cyber incidents that the Industrial Control Systems Cyber Emergency Response Team responded to in 2016.

“AM digital information is at risk,” White says. “You must have secure enterprise governance and IT support, and PLM can help with this. Remember, PLM is a business strategy, not a software tool, and design for additive manufacturing (DFAM) falls under PLM.”

Currently, the workflow for DFAM is flawed, as the mix of human, generative, simulation and optimization stages is not seamlessly connected, which leads to out-of-control issues, lost time and an increased risk for error. At the same time, PLM templates and forms don’t consider AM. PLM templates are designed for traditional manufacturing.

“Basically, PLM exists to manage product information of traditionally made products,” White says. “Now we introduce either an AM part mixed into a traditional part or a wholly AM part, and all the corporate standards that are in place for traditionally made parts in PLM—forms, search, workflows, bill of materials (BOM) structures, release processes, integrations to other applications such as ERP and change management—are not expecting an AM part with its unique characteristics.”

AM As a Workstream of PLM

So, how do we implement PLM to manage AM parts and processes? Let’s take a closer look at AM as a workstream of PLM because, in the end, the AM product needs to meet all the same corporate standards of cost/time, quality, stock keeping, unit numbering and so on as a traditional one to be shipped to customers. “For example, if a single AM part in a car, plane, iPhone, etc. is not meeting all governance standards, it might jeopardize the entire product. Think of the Space Shuttle Challenger, Prius, Tesla and Samsung Galaxy,” White says.

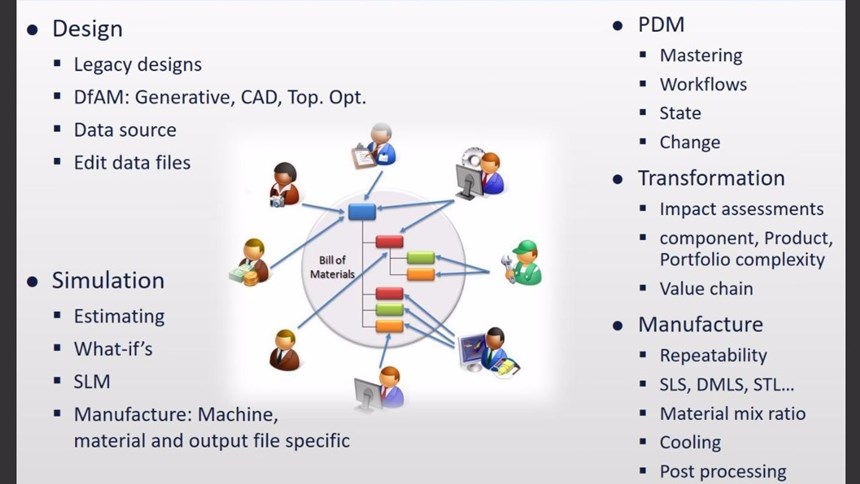

PLM provides governance over the planning, conceptualization, design, validation, production and service of the manufacturing process, while AM touches various departments, disciplines, workflows and systems across an entire enterprise—for example, file editing, material management, controlled cooling, trials, production and postprocessing. This implementation requires flexibility and business transformation.

“AM intersects with design, simulation, topology optimization, PDM and manufacturing, and when fully embraced, it requires business transformation. Because there are things we can stop doing by adopting AM, but there are new things we must start doing. So, we must consider the business impact,” White says.

At the center of this workstream is the BOM, which includes DFAM and everything else downstream of design. Here is how White explains the product information flows through a company in an AM enterprise and how PLM manages the digital data as it progresses: Product structures start as requirements, which become features in a BOM that move through the workflow (engineering to manufacturing, etc.) collecting more data as they go along. All parts must adhere to defined quality, cost and time metrics to ensure the final product can be shipped. AM presents different challenges compared to traditionally manufactured products, as AM engineers need the ability to print or manufacture parts throughout the product’s lifecycle. PLM must embrace and support AM processes to enable a company to scale AM into production.

The DFAM Pyramid

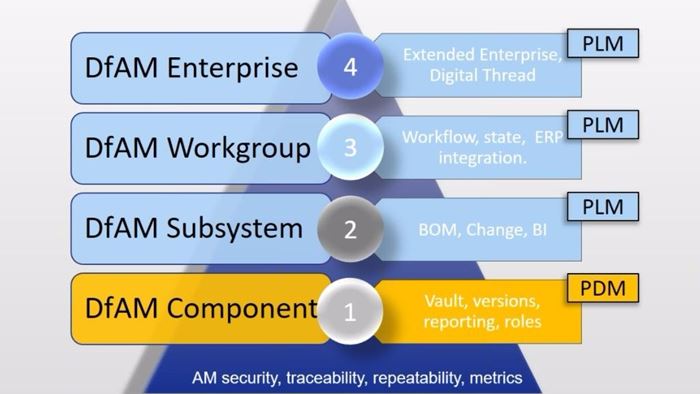

CIMdata has developed a four-tier approach to implement PLM for managing AM parts and processes called the DFAM Pyramid (see Figure 1 above). A foundation of AM security, traceability, repeatability and metrics supports the four DFAM tiers: component, subsystem, workgroup and enterprise. The component tier represents single parts; the subsystem tier represents a collection of parts; and the workgroup and enterprise tiers introduce the organizational aspects of making components and subsystems, representing how a company functions.

Here are the data management capabilities required at each of the tiers, which illustrate the digital thread that connects all the AM information throughout the product’s lifecycle:

| Pyramid Tier | Required Data Management | |

| 1 | DFAM Component | plan, data, approach and management, requiring PDM as a basic management tool |

| 2 | DFAM Subsystem | BOM, change and business intelligence, requiring PLM |

| 3 | DFAM Workgroup | workflow, state and ERP integration, requiring PLM |

| 4 | DFAM Enterprise | extended enterprise and digital thread, requiring PLM |

To implement DFAM one must consider the AM workgroup (the work activity closely coupled with the machine) and its workflow (powder management, CAD/CAE, PDM, printing, cooling, unpacking and postprocessing), as well as the enterprise (all the other departments and tools outside of that AM workgroup that are involved).

“The AM workgroup wants autonomy and is treated like a production machine, when in reality, each side must share data and keep each other in sync when changes occur,” White says. Exploring the interaction between the two sides helps reconcile the flexibility demands of the AM workgroup with the governance requirements of PLM.

How can companies achieve needed governance using PLM to keep track of the AM workgroup workflow? The ideal workgroup interaction requires striking the right balance between PLM and AM and keeping everything traceable and repeatable. This includes:

- AM workgroup members using PLM to manage the specific AM workflow for simulation lifecycle management, PDM, AM production, quality, machine/material characteristics and postprocessing.

- The engineering department executing quality tasks or changes to geometry and structure using PLM with automated version/revision control.

- AM workgroup members accessing PLM using specific AM templates, search fields and forms, linked to a PLM database.

- AM workgroup members linking AM workgroup software solutions and PLM, so that business intelligence dashboards show the state of all AM components against defined key performance indicators such as time, material and cost.

Related Content

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreTwo 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More