Optimizing Metal Powders for Additive Manufacturing

What makes a good metal powder for additive manufacturing? Case study data highlights the value of particle size and shape, powder flowability, and bulk density.

Additive manufacturing offers specific advantages relative to alternative powder metallurgy methods, ranging from design flexibility to the potential for high material use efficiency. To fully exploit these potential benefits, manufacturers need to understand the process, the properties of material inputs and interactions between the two, so as to exert effective control.

There are a number of alternative technologies used within AM machines—including powder-bed fusion, electron beam melting (EBM), binder jetting and directed energy deposition (DED)—each of which subjects a metal powder to different flow, stress and processing regimes. Matching powder characteristics to any specific application/machine is crucial, as is identifying analytical tools that can be used to reliably set specifications for AM metal powders to validate quality and manage their use.

This article reviews the characteristics of metal powders suitable for additive manufacturing applications. Case study data from the National Centre for Additive Manufacturing, part of the UK’s Manufacturing Technology Centre (MTC), highlights the value of particle size and shape, powder flowability, and bulk density measurements in the selection, optimization and management of AM powders.

What Makes a Good AM Metal Powder?

AM processes are typically operated with “fixed” parameters for a specific application, with current machines offering little opportunity for any form of responsive control. This means that inconsistent input material properties will translate directly into inconsistent finished component properties. Poor powder quality can produce defects in the end part including pores, cracks, inclusions, residual stresses and suboptimal surface roughness, as well as compromising throughput. Understanding the correlations between material properties, processing performance and end component properties is therefore essential, both to select the best powder for an application and to ensure the consistency of that powder—from build-to-build and layer-to-layer, as well as through recycling. This raises the question of which properties are important in terms of defining a robust powder specification.

Chemistry is paramount. A powder needs to comply with the alloy composition of the material specified, and grade must be carefully selected so as to control the interstitial elements present—such as oxygen or nitrogen—which can impact the properties of the finished part. In addition, AM powders must be free from foreign particulate contamination, such as from other material batches at the powder production plant or the AM facility, or debris in processing/recycling equipment. Contaminant levels of just a few parts per million can be significant in terms of component quality.

Beyond chemistry, the physical characteristics of a metal powder define AM performance. These characteristics include both bulk properties of the powder and properties of the individual metal particles. Key bulk properties are packing density and flowability. Powders that pack consistently well to give a high density are associated with the production of components with fewer flaws and consistent quality. Flowability, on the other hand, is arguably more closely associated with process efficiency. The ability to spread evenly and smoothly across a bed, and to form a uniform layer with no air voids is essential for powder-bed fusion processes, for example, while consistent flowability under very different conditions, as an aerated powder stream, is required for directed energy deposition. These requirements intensify as processing speeds are increased.

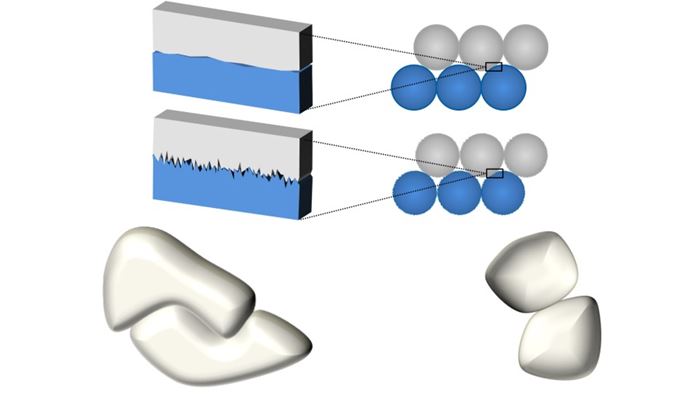

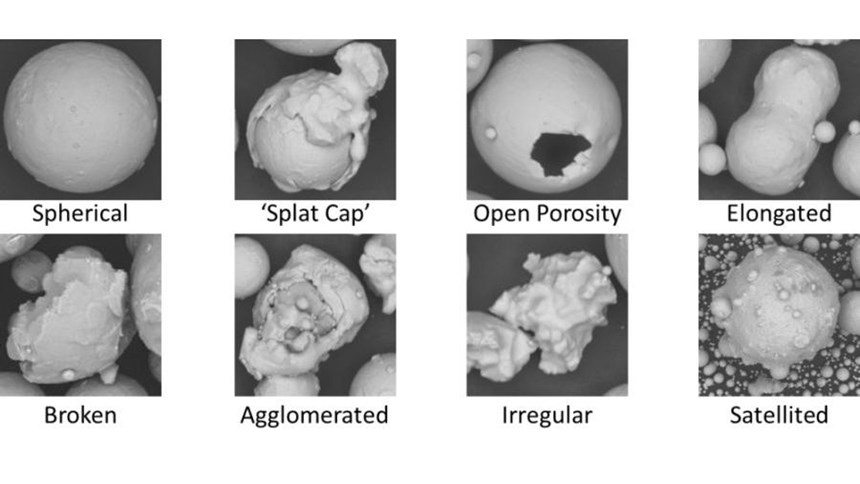

Both bulk density and flowability are directly, though not exclusively, influenced by particle size and shape. The range of particle characteristics known to influence flowability, for example, includes stiffness, porosity, surface texture, density and electrostatic charge. Figure 1 illustrates the relationship between aspects of particle shape and powder flowability. Generally speaking, smooth, regular-shaped particles flow more easily than those with a rough surface and/or irregular shape. Rougher surfaces result in increased interparticular friction while irregularly shaped particles are more prone to mechanical interlocking; both of these effects decrease flowability.

Similarly, spherical particles tend to pack more efficiently than those that are irregular giving rise to higher bulk densities. The bulk powder property requirements for AM therefore suggest that sphericity is likely to be highly prized, a conclusion widely recognized within the industry.

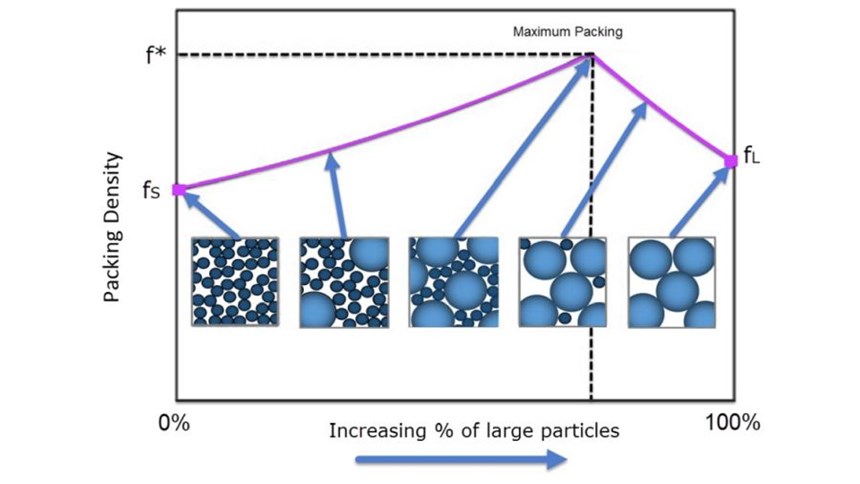

When it comes to particle size, AM metal powders are necessarily fine to, for example, meet the requirement to form a powder bed just tens of microns thick. However, fines can be problematic from a health and safety perspective, and in terms of flowability. Because the forces of attraction between particles increase with decreasing particle size, finer powders are usually less free-flowing than coarser analogues, though optimizing particle shape can help to mitigate this effect. In terms of packing, Figure 2 shows how both particle size and particle size distribution are influential. Maximum packing density is achieved with a distribution that includes both coarse and fine particles, with finer particles increasing density by filling the interstices left by larger ones.

Making Metal Powders

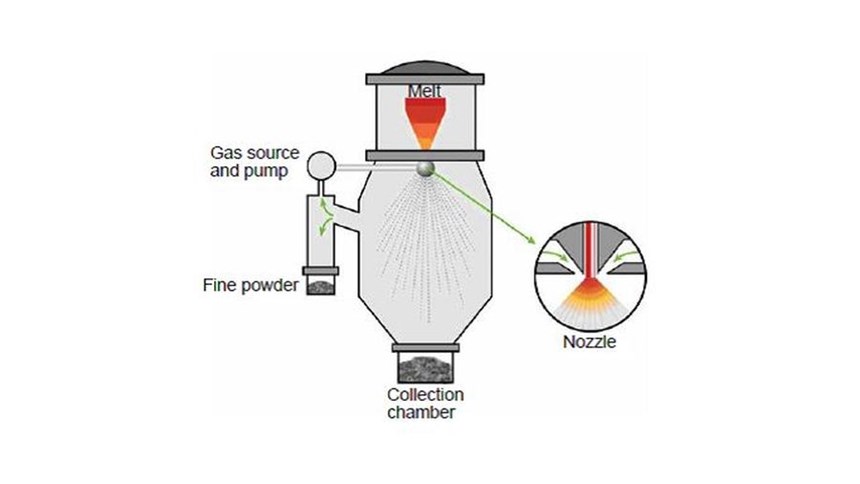

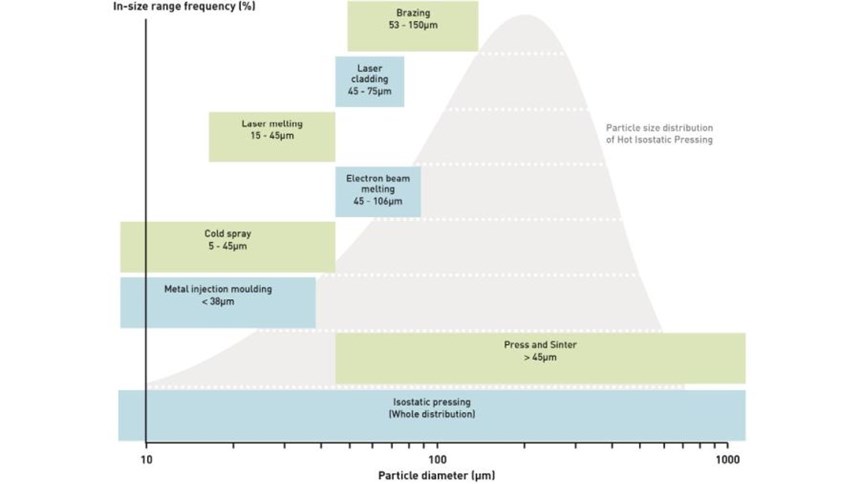

Metal powder manufacture predates AM and many chemically consistent products are available. The majority of metal powders used in AM are produced by gas atomization, depicted in Figure 3. In this process, a feedstock is melted in a crucible and then ejected through a nozzle into a high-pressure gas stream (usually argon or nitrogen), breaking the molten stream into droplets.

The size of particles produced by gas atomization can be controlled by varying process parameters such as: gas pressure; melt properties; nozzle design, and gas-to-metal ratio. However, the resulting product is not ideal for AM processes, which optimally require a narrower particle size distribution as shown in Figure 4. Various post atomization processes including “scalping” to remove the oversize particles followed by either air classification or sieving are applied to obtain the required size fraction. The lower atomization yields that result from the narrow size distributions required for AM is one of the factors that increases the cost of AM powders.

With regards to shape, gas atomized particles are relatively spherical but may exhibit any of the features shown in Figure 5. In particular, satellited particles are a problem—not only for flowability and packing, but because the satellite particles are so small (usually 1 to 10 microns), that if detached, can become an airborne health and safety risk. More spherical particles can be produced by plasma atomization or the Plasma Rotating Electrode Process (PREP), but at a higher price. Measuring powders and particles so as to determine exactly what is required for a given process is the key to achieving beneficial performance at a competitive cost.

Evaluating Metal Powder Supplies for AM Applications

Researchers at MTC assessed three chemically identical Ti6/4 metal powder samples from different suppliers to assess their suitability for AM applications. All three powders met a specification for EBM with a nominal particle size distribution of 45 to 106 microns; two were produced via the same process but supplied by different vendors, while the third was produced using a different process. Details of the manufacturing processes applied were not supplied.

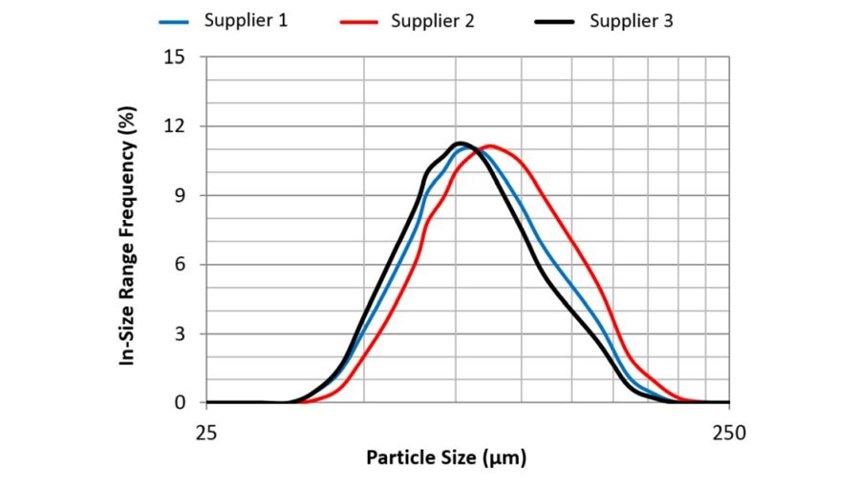

Particle size distribution data were measured for each of the powders with laser diffraction using a Mastersizer 3000 from Malvern Instruments. The results are shown in Figure 6 and indicate that all three have a desirable monomodal particle size distribution. However, there are clear differences in the Dv50 (the particle size below which 50 percent of the particles lie, on the basis of volume) most significantly in the coarser end of the distribution. The material from supplier 2 has a higher level of coarse material than either of the other two, suggesting that the process used to narrow down the particle size distribution of the powder has been less successful.

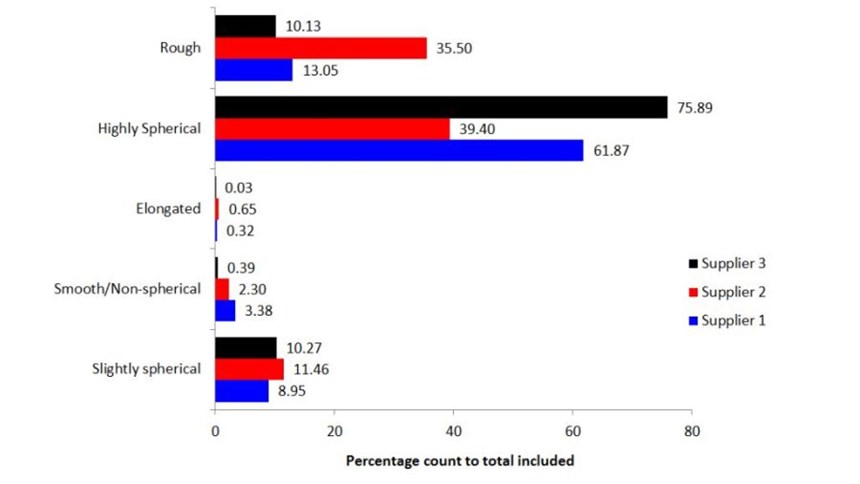

Samples of each supply were subsequently characterized using a Morphologi G3 fully automated image analysis system from Malvern Instruments. The system captures particle images that can be used to generate statistically valid size and shape distributions to characterize particle morphology. Using well-defined parameters, such as elongation and circularity, which define overall shape, and convexity, which quantifies the regularity of the outline of the particle, the particles in each sample were classified according to the following descriptions: rough particles; highly spherical particles; elongated particles; smooth non-spherical particles; and slightly spherical (see Figure 7).

The identified differences in the particle morphology of the three supplies suggest that the powder from supplier 1 will perform most effectively in AM processes. However, to understand securely the potential impact of these differences, and/or detect further differences that may influence process performance, it was necessary to measure relevant bulk powder properties—flowability and bulk density.

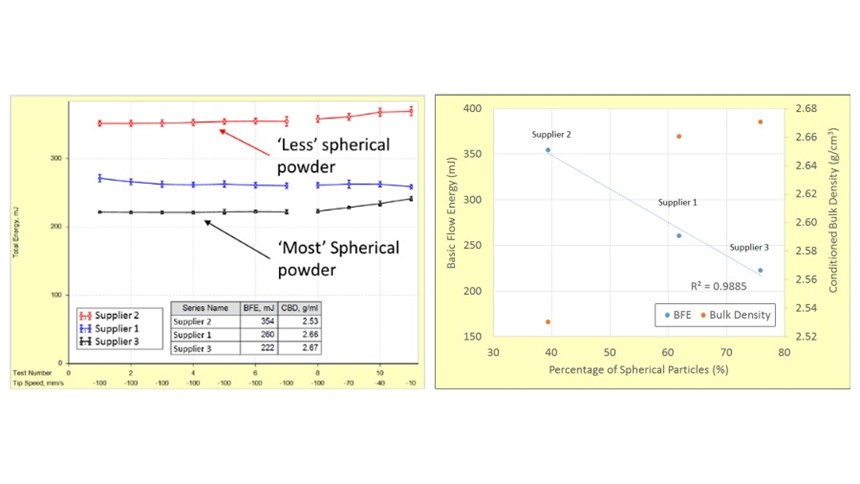

Dynamic powder flow measurements were made for all three powders. This type of testing measures powders in motion, rather than in a static state, generating flow energy values from precise measurements of the axial and rotational forces acting on a blade as it is precisely rotated through a powder sample. Basic Flow Energy (BFE), a primary dynamic property, has been shown to be highly relevant to the performance of metal powders in AM processes.

Figure 8 shows BFE measurements for the each of the powders. There is a strong correlation between dynamic flowability and the percentage of spherical particles in the sample. Powders that contained a greater quantity of spherical particles exhibited less resistance to flow than those with fewer. For these powders, the correlation between particle morphology and flow appears to be largely independent of minor differences in particle. The bulk density of the samples was also measured using the FT4 Powder Rheometer in order to assess packing density. The correlation with shape is less robust, possibly due to the influence of other factors, such as particle size, but there remains a clear trend associating greater spherical particle content with enhanced packing efficiency.

These results show that chemical consistency is no guarantee that physical properties, and consequently AM performance, will be identical, and illustrate the value of applying size, shape and flowability measurement to assess the performance of an AM process. Particle size and shape are the parameters that are most easily specified and controlled in the production of metal powders, while flowability and bulk density assessments provide a sensitive, process-relevant interpretation of the impact that changes in these variables may have on performance in an AM process. In this instance, these techniques combine to identify the powder from supplier 1 as being the best choice of the three for AM applications.

The extent to which AM becomes a mainstream manufacturing option depends equally on the development of AM technology, and the identification of powders that will work efficiently with it, to produce high-quality components. Using complementary techniques, such as advanced automated image analysis and dynamic powder flow measurement, helps manufacturers to identify and specify suitable powders, optimize AM processes, monitor batch consistency, implement effective powder recycling strategies and achieve consistently high-quality parts. These same technologies can also help powder suppliers to optimize their processes to meet the requirements associated with supplying growing and lucrative AM markets. Ensuring a supply chain of consistent and appropriate quality is an essential step towards fully exploiting the considerable potential of AM across all the industries where it can bring benefit and commercial value.

Related Content

This Year I Have Seen a Lot of AM for the Military — What Is Going On?

Audience members have similar questions. What is the Department of Defense’s interest in making hardware via 3D printing over conventional methods? Here are three manufacturing concerns that are particular to the military.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreRead Next

Computer Vision System Automates Characterization of Metal Powder

A computer vision system that has learned to classify metal powders could speed material qualification and advance machine learning in additive manufacturing.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More