MT Community Reconnects at IMTS 2022

We’re back, better and implementing digital technology.

As people met each other with smiles, hugs and handshakes, the connectedness of the manufacturing community was the literal showstopper at IMTS 2022, which achieved a total registration of 86,307 and 1,211,206 million square feet of exhibit space representing 1,815 exhibitors.

“While the excitement and electricity were evident in every aisle of the show, what was most gratifying for the industry — and frankly, the country — was the scope of commerce taking place,” says Douglas K. Woods, president of AMT – The Association For Manufacturing Technology, which owns and produces IMTS. “Visitors sought out and found key technologies and productivity solutions to move their businesses forward.”

The manufacturing community achieved something that hasn’t been done since World War II: it brought our industry back together after a worldwide disruption. We proved our resiliency, but we achieved much more. The digital technologies and other new products at this show aren’t just advanced: they are accessible, inclusive and ready to be implemented by small and medium businesses regardless of their workforce composition.

AM - Expansive Presence at IMTS 2022

IMTS first broadly exposed AM technology to manufacturing audiences in 2014 with the AMT Emerging Technology Center (ETC), which highlights disruptive technologies.

Recognizing that additive processes would join subtractive as a core manufacturing technology, IMTS created the Additive Manufacturing Pavilion in 2016. That first AM Pavilion featured 20 exhibitors and occupied 15,900 square feet. By IMTS 2018, demand for AM space nearly doubled to accommodate 44 exhibitors and expand the pavilion to 29,500 square feet.

Melanie Lang, Formalloy co-founder and CEO, displays a large metal part made from the company’s direct energy deposition machine.

In the ensuing four years, demand for space and the number of exhibitors nearly doubled again as the AM Pavilion at IMTS 2022 featured nearly 100 exhibitors and occupied 50,725 square feet. In addition, exhibitors throughout McCormick Place showcased AM-specific technologies.

The AM technology on display solves mainstream industrial challenges in ways unimaginable just a few years ago. Additive and other digital manufacturing technologies are also the most efficient way to create lean supply chains, and IMTS showcases the most complete breadth and depth of digital technologies available.

IMTS 2022 provided multiple resources for manufacturers at all levels of AM knowledge. The event featured exhibits, demonstrations, conference speakers, expert panels and workshops showcasing AM hardware and software solutions that help deliver parts and products to a wide range of industries —from aerospace and automotive to construction and medical.

AM Beyond the AM Pavilion

AM technologies could be found in all four event buildings — not just in the Additive Manufacturing Pavilion where nearly 100 exhibitors exhibited the latest solutions in AM technologies, materials, hardware and software. Another nearly 200 exhibitors with equipment and software related to AM were spread throughout McCormick Place. Additional software providers were in the Controls & CAD/CAM Pavilion. The Metal Removal Pavilion featured exhibitors with hybrid solutions (subtractive manufacturing machines with additive processes). Inspection solutions were in the Quality Assurance Pavilion.

Alex Kingsbury, industry consultant at Additive Economics, moderates the panel “3D Technologies, The Good, The Not-So-Good, and Stuff You Need to Know” on the AM4U stage, presented by Formnext.

In its debut, the AM4U Area, presented by Formnext, featured well-attended daily presentations such as a panel of nine AM experts discussing the benefits and drawbacks of various AM technologies. AMT, Gardner Business Media and the organizers of Formnext announced they are planning three new AM events — Formnext Forum Austin (Aug. 28-30, 2023), Formnext Forum co-located at IMTS 2024 and Formnext Chicago (April 8-10, 2025) at McCormick Place.

AM’s Impact on Space Exploration

Visitors to the AMT Emerging Technology Center (ETC) walked into a scaled, 3D printed section of the Rosenberg Space Habitat. They saw live demonstrations of the robotic 3D printing technology used to make the lunar structure thanks to the collaboration of IMTS exhibitors Siemens and Ingersoll Machine Tools Inc. “Space explorers can’t bring everything necessary to colonize space. This demands that we develop a space manufacturing economy,” says Ingersoll CEO Dr. Jeffrey Ahrstrom. “As you walk around the show, the presence of additive manufacturing is significant. No longer the stuff of research labs, it is mainstream and driving active change throughout the capital equipment industry.”

AM-Focused Conferences and Events

IMTS 2022 was the home of two AM conference events sponsored by Gardner Business Media. The AM Conference featured quality technical content our attendees have come to expect and it served as a perfect launching point as the AM Conference evolves into Formnext Forum Austin in August. Modern Machine Shop brought its Top Shops program to IMTS. The 3D Printing Workshop for Job Shops seminar demonstrated ways 3D printing can complement CNC machining and make machining operations, systems and workflow more effective.

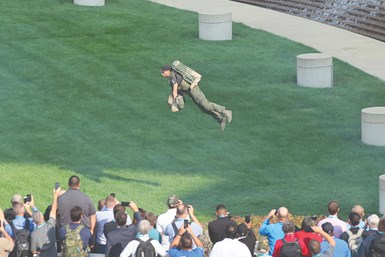

New Frontier in Human Flight

In the future, we were promised Jet Suits, and Richard Browning (manufacturer, technologist and founder of Gravity Industries) delivered. Browning made three flights in his patented Jet Suit in front of McCormick Place. The suit uses many 3D printed components, yet Browning remains impressed with the 3D printed exotic alloy components in the AM Pavilion, as well as scaling of large additive components, as demonstrated in the ETC.

Investment in Advanced Manufacturing

Keynote speaker Barbara Humpton, CEO of Siemens USA, and Tim Shinbara, AMT CTO, discussed the recent government investment in the semiconductor industry, its implications for the private sector and its connection to the IMTS Investor Forum.

Barbara Humpton, Siemens USA CEO, and Tim Shinbara, AMT CTO, explored recent government investment in the semiconductor industry, its implications for the private sector and its connection to the IMTS Investor Forum.

“I’m delighted to see the investment community stepping up to the plate,” Humpton says. “Because — while we face disruption in Europe due to energy and while we face disruption in Asia due to the pandemic — we in the U.S. have relative health [… and] energy security. Now is a time when builders in America can get going. We’ve got makers all across the country ready to bring manufacturing back close to the source of demand, and we [Siemens] stand ready with the technology to do it.”

The inaugural IMTS Investor Forum, powered by AMT, featured curated tours on AM, digital technology, machining and automation, and was designed to help the investment community understand the opportunities in manufacturing.

“With the number of innovative products hitting the market now — cutting across the entire swath of automation and digital technologies that change the way we manufacture parts — we’re in a period of time that will not be paralleled again for decades,” says presenter David Burns, a principal and founder at Global Business Advisory Services. Burns points out that manufacturing technology orders per sale continued to increase from 2019 through 2022 and that they will continue to accelerate as companies use technology to compensate for a smaller labor force.

Automation

Automated technologies could be found in every hall with solutions for high-mix, low-volume applications to help job shops address their workforce and productivity issues. “The automation systems at IMTS focused on ease-of-deployment, iPhone-level programming simplicity and affordability for small and medium businesses,” Shinbara says.

Motivating Technical Education and Careers

Working closely with exhibitor partners, the Smartforce Student Summit at IMTS 2022 presented 24,000 square feet of interactive experiences and attracted 11,715 students. “We showed students choices in the education-to-a-career pathway that they might not have considered,” says Greg Jones, AMT vice president, Smartforce Development.

One of those students was Saylor White, who wanted to visit IMTS with her father Todd White for a very special 10th birthday. Todd White operates Todd White Metal Works, a small shop in Glendale, Arizona.

“My favorite part of the show was the student area,” Saylor says. “You can only look at machines on the show floor, but here in the Student Summit, you can actually touch them. That can bring more kids into machining.”

(left to right) Andrew Crowe, founder, New American Renaissance Tour, and Onome Scott-Emuakpor, aerospace engineer at the USAF Research Laboratory, discuss “The Struggle and The Progress of Minority Business Founders.” Watch on IMTS+ at gbm.media/IMTSplus-minoritybiz

The opportunity in manufacturing is for all of us, according to Andrew Crowe, founder of the New American Manufacturing Renaissance. “The collaborations have been crazy positive. This show is historic, and people are going to point to IMTS 2022 as a catalyst,” Crowe says.

When the MT community connects and collaborates with friends to solve problems, what can we say but, “Dang, we’re better together!”

Related Content

AM Workshop at IMTS: Succeeding With Powder Bed Fusion

A half-day event at the International Manufacturing Technology Show focuses on tactics for success for machine shops and other manufacturers preparing to embrace production 3D printing via powder bed fusion.

Read MoreInnovation is Revving Up: ‘Manufacturing Explorers’ Season 3

Buckle up and join Max and Travis as they talk about the thrills of visiting innovative automotive companies in the premiere of their third and final season of “Manufacturing Explorers,” an IMTS+ original series.

Read MoreHeron AM Offers Robotic LFAM for Composite Pellet Extrusion

The integrated Heron AM system opens up new opportunities for manufacturers seeking to drive new applications more efficiently and sustainably.

Read MoreVideo: Laser Powder Bed Fusion Platform Designed for Safety, Ease of Use

One Click Metal’s compact metal 3D printing platform offers powder handling features to make this affordable system accessible and safe for many types of facilities. See one application in this video, filmed at IMTS 2024.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More