Four Tips for Moving to Additive Production

Sponsored ContentFollow these steps to develop a coherent strategy for entering the world of additive manufacturing.

Share

More and more companies are recognizing the potential of additive manufacturing (AM) as the technology is becoming a viable production process. However, not every company has the knowledge and experience to launch into AM production, and it can be daunting to invest in it when you lack experience.

One way to ease your business into adopting AM is to put a plan together. Looking at how companies have found success in AM production, a clear pattern emerges that you can use to set up your own additive operation. Here are four tips for finding success in AM.

Step 1: Develop a Clear Goal

By 3D printing this pump impeller out of plastic instead of making it out of metal, we were able to eliminate the potential points of failure that result from welding.

There are numerous benefits to AM, but it is vital that businesses decide what benefits are most important to them before leaping into the water. According to John Nanry – who oversees all engineering, manufacturing and operations at Fast Radius as the company's Co-founder and Chief Fulfillment Officer – “When you have a clear, identifiable goal, you can use that to guide your approach to AM, and your company can use it to evaluate your success.” The benefits of AM tend to fall into three categories: product improvements, operational efficiency and sustainability.

- Product improvements are direct enhancements to the product you produce, such as shapes that are impossible using other processes, resulting in parts that are much more efficient than was previously possible. Other improvements include using iterative design to quickly produce and test prototype parts, making it easier to improve on a design, as well as mass customization to rapidly produce custom parts.

- Operational efficiency refers to improvements to the production process that would either be impossible or prohibitively difficult without AM. This can include avoiding the cost of tooling for low-volume parts, or even producing parts while the tooling is being manufactured. Additionally, shops can store digital files of available parts, making it easier for customers to peruse and buy from your store.

- Sustainability refers to AM’s capacity to decrease the need for resources, reducing the environmental impact of manufacturing. AM reduces the amount of material used, as well as material waste. Additionally, the reduced transportation costs for material and from producing parts closer to their destinations reduces your carbon footprint.

It is also important to prepare your business for an iterative design process. Rapid prototyping through AM tends to create an overlap between the design and production phases of making parts. “The technology that you use to create prototypes is the same you use to make parts,” says Nanry. “This means there’s no need for extra work to develop a manufacturing method.” Additionally, the ability to test and refine a part blends the design and production processes, which enables you to both improve upon and accelerate the product development cycle.

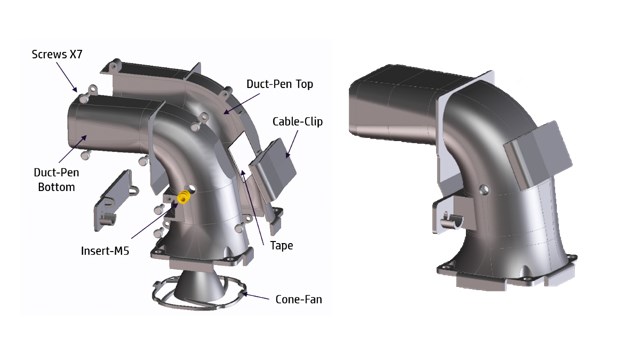

AM provides numerous examples of potential improvements. For example, Fast Radius manufactures the cooling duct in the HP 500/300 printer series using HP MJF. By consolidating eight parts (primarily metal) into one, HP was able to simplify their supply chain and lower the component cost by 30%.

Step 2: Identify the Technology and Personnel Needed

Once you know why you want to enter AM and have a part in mind, the next step is to figure out which technologies will best serve your goals. “There is a wide range of AM technologies on the market, and more materials are being developed all the time,” says Nanry. “It can be challenging to figure out which one is best for you.”

Material needs narrow down the possible technologies a shop can use. For example, the HP 300/500 can produce parts in a wide variety of thermoplastic materials, but not metal.

One good starting point is to form a short list of feasible materials, considering all part requirements. Nanry says,“Each printer can only work with a certain selection of materials.” This means your functional requirements will narrow down the combination of printing technology and materials that can achieve the desired performance.

Once you have the technology in mind, it is important to have stakeholders invested in the success of the AM process. This can be a combination of both internal and external personnel, and it should include people with AM expertise as well as engineers experienced in design and quality management.

Step 3: Design for Additive

Once you have the people and technology, it is time to design your product. Designing for additive is an iterative process that requires a specialized skill set. The design, testing, and production of a part overlap much more than in traditional manufacturing, and it is important to account for that. Generally, the AM design cycle occurs in three stages: identify potential improvements, evaluate the part, then iterate on that design.

These landing gear pads by Satair are critical components in an assembly used during main landing gear maintenance events for Airbus planes. Fast Radius used topology optimization techniques to redesign the pads for additive manufacturing, improving manufacturing yield, reducing post-processing time, and cutting material usage by 60%.

The initial stage is perfectly simple: identify areas of improvement. “AM offers a lot of options for improvement,” Nanry says. “Would it benefit from an extra cooling channel? Can you reduce weight without affecting strength?” Once you identify areas of improvement, it is time to evaluate your design. Does its shape require support structures? Will it require post-processing? These are all important considerations to make ahead of printing. Doing so will prevent design failures and shorten the prototyping process. Once this evaluation is done, you can look for further cost savings. Optimizing material use and part orientation, for example, can provide excellent cost savings.

The final part of the design cycle is iterating the design. “With AM, you can rapidly test, evaluate and redesign the part,” Nanry says. “Instead of spending months perfecting a single, expensive mold, you can print a part in hours or days and test it immediately.” This makes it possible to test the part in real conditions, identify failures, and improve on the design in less time than it can take to manufacture a single mold.

Step 4: Manufacturing the Part In-House or with a Partner?

The final phase of the manufacturing cycle for AM is making the part. One of the major questions to answer at this stage is whether to make the part in-house or partner with an experienced AM manufacturer.

Fast Radius has the resources to assist your business in developing numerous approaches to AM. This ranges from iterative prototyping to full production-capable machines like the Stratasys F900.

According to Nanry, the question is rarely clear cut. “Producing AM parts yourself means making major investments in both infrastructure and personnel.” These investments include facilities, printers and software, in addition to personnel familiar with additive and equipment for post-processing.

Staring down the barrel of these investments can make partnering with an AM manufacturer very appealing. Companies like Fast Radius are experienced in working with businesses to develop parts and produce them in high volumes. According to Nanry, evaluating your partner is as important as every other step in the process. “A good partner will have an engineering staff with experience creating repeatable, reliable parts,” he says. Fast Radius in particular has experience in a wide range of industries and offers both consulting and manufacturing services.

If you’re interested in learning more, Fast Radius created a playbook for converting parts to additive, which you can download here. You can also contact them for more information.