Experts Compile Skills, Attributes Necessary for AM Engineers

Additive engineer demand has begun outpacing the supply of qualified workers in the industry. Penn State University banded together a team of experts and implemented focus groups, interviews, location observations and surveys in order to find out what makes a good additive manufacturing (AM) engineer.

Interest in additive manufacturing (AM) continues to grow in many industries. The high demand for jobs in AM design, engineering and production has outpaced the supply of workers, particularly for engineers with AM experience. Companies are desperate to identify AM engineers who are knowledgeable and can immediately contribute to their AM team and initiatives; unfortunately, we know little about what attributes make an AM engineer successful.

While anyone can buy a 3D printer and start printing, the qualities that make a skilled AM engineer remain unclear. Are the attributes for AM engineering success the same as those for good engineers in general or does the AM engineer require new skills and capabilities? Companies—and educators—have years of experience to draw on when teaching engineers about traditional manufacturing methods (machining, casting, forging, etc.), but they need insight to identify a good AM engineer given the nascent and rapidly evolving state of AM technology. Our recent research explores the traits of successful AM engineers and offers some conclusions.

What We Did

Given the emerging trends and increasing interest in industry, it is important to identify specific characteristics of engineers who can help companies realize the competitive advantage that AM offers. To that end, an interdisciplinary team was created, combining an engineering professor at the leading edge of AM and its application in industry and a team of industrial-organizational psychologists with expertise in strategic job analysis and organizational research methods. The team gathered data on what makes an engineer successful when working with AM.

The team followed a multi-step process and accepted protocols to perform a strategic job analysis by: conducting observation at two AM sites (one academic, one industrial) to familiarize the team with AM facilities, technology, roles and responsibilities; convening focus groups and interviews with eight AM experts in academia and industry to learn what they thought were the key knowledge, skills, abilities and traits to perform well; and analyzing survey responses from 124 practicing AM engineers in a range of industries (e.g., aerospace, automotive, consumer goods, medical, space) recruited from AM workshops and professional contacts, rating the importance of those knowledge, skills, abilities and traits.

Results and Key Findings

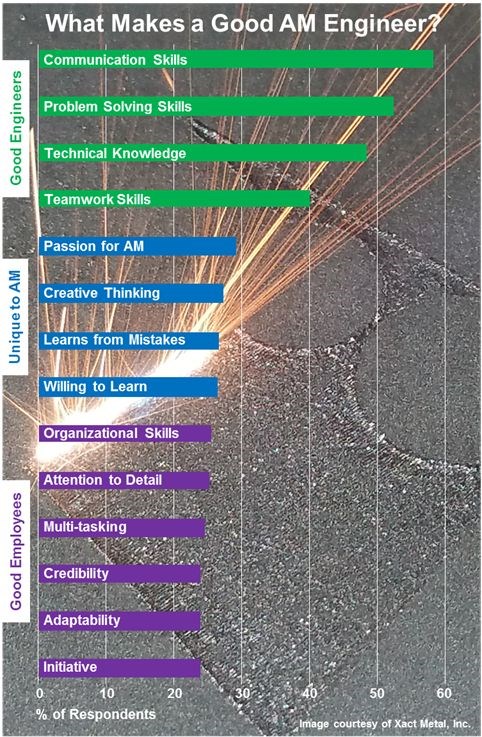

A common set of attributes emerged repeatedly as the team synthesized data across the three sources. Key findings include:

- The top four attributes—communication skills, problem-solving skills, technical knowledge and teamwork skills—are the same as those considered important by the Accreditation Board for Engineering and Technology (ABET), suggesting that the attributes of traditional engineering are still important for AM. This is good news for educators, namely because it eliminates the necessity of revamping the entire engineering curriculum for AM.

- The next four attributes—passion for AM, creative thinking, learning from mistakes and willingness to learn—are unique to AM and reflect the emergent state of the technology. These skills are likely important when working with any new technology, not just AM.

- The last six attributes that emerged—organizational skills, attention to detail, multi-tasking, credibility, adaptability and initiative—are skills a company would look for in any good employee. These skills are particularly important for AM given the current state of the technology and how quickly it is changing.

- Follow-up analyses confirmed that the attributes did not vary by industry, a person’s tenure in his/her position or leadership position with one exception: supervisors rated credibility, organizational skills, multitasking and attention to detail significantly higher than non-supervisors.

Implications and Next Steps

Given the consistency of the results across all respondents, companies moving into AM should consider adding these AM-specific attributes into their job posting(s) if they have not already done so. We are currently gathering validation evidence from supervisors and employees to determine whether these qualities also predict the performance of AM engineers working in industry. If so, then assessing the qualities of job applicants during the selection process will be important when hiring AM engineers.

Meanwhile, engineering educators need to continue stressing the importance of ABET’s top skills and find ways to cultivate a passion for AM, practice creative thinking and nurture an open mindset that is willing to learn from mistakes and learn new things in the classroom. If engineering educators can do that, then students will have no problem finding good jobs and helping companies on their AM journey.

Related Content

Lessons in Personalized Production From the 3D Systems Surgical Guide Process

Tailor-made manufacturing is one of AM’s richest possibilities, but the success factors inevitably draw on more than AM.

Read MoreSpatter, Surrogate Modeling and More Advanced Manufacturing Research Happening at Carnegie Mellon University: AM Radio #53

In this trip report, we discuss research at the Manufacturing Futures Institute and Next Manufacturing Center, both under CMU’s umbrella, to advance industry with robotics, AI and additive manufacturing.

Read MoreSiemens’ Engineering HEEDS AI Simulation Predictor Optimizes Additive Manufacturing

The HEEDS AI Simulation Predictor empowers organizations to take full advantage of the digital twin to optimize products through advanced state-of-the-art artificial intelligence with built-in accuracy awareness.

Read MoreVixiv Developing AI Alternative to Generative Design

Newly opened Ohio facility is where geometric cells are made and tested to inform the machine learning system that will “know,” without computation, what 3D printed form satisfies a given set of needs.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More