Exclusive Insights From Formnext Forum Austin

AMT — The Association for Manufacturing has partnered with Additive Manufacturing Media, Gardner Business Media and Mesago Messe Frankfurt to bring new Formnext events to North America.

Featured in the ORNL display in the AMT ETC are a 3D printed wind blade and the world’s first 3D printed excavator and wind blade.

The Formnext brand needs no introduction in the additive manufacturing (AM) community. Mesago Messe Frankfurt has produced Formnext for years, growing the show to be the largest industrial AM event in the world. Now, with the help of AMT - The Association For Manufacturing Technology and Gardner Business Media, the event has a presence in the United States:

- AM Sector, Accelerated by Formnext, at IMTS 2024 — Sept. 9-14, 2024

- Formnext Chicago — April 8-10, 2025.

To kick off the new partnership, the organizations hosted Formnext Forum Austin in August. More than 1,000 attendees joined the AM community for this three-day event featuring keynotes from EOS and Seurat, sessions on different technologies, and exhibits from dozens of companies and organizations.

If you attended, you would have listened to a presentation from EOS and the U.S. Navy detailing the use of AM to advance supply chain resiliency in submarine manufacturing and development. You might have seen a custom heat exchanger for testing the pre-burners on Launcher’s E-1 rocket engines, made using NASA’s new GRCop-42 alloy. You could have learned about the next generation of medical devices, powered by design for additive manufacturing (DfAM). But summaries about those and other presentations are available online.

Here are some things you missed that you could only appreciate by being there:

- Facility Tours — On the first day of the event, participants toured the state-of-the-art factory floors of Cumberland Additive and EOS, getting a view of AM in action. (If you’ve never seen a laser powder bed fusion machine operating in real life, it doesn’t compare to the videos!)

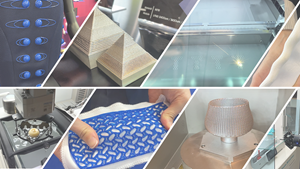

- AMT Emerging Technology Center (ETC) — Offering a glimpse into the possibilities of industrial 3D printing, the ETC featured innovations from the U.S. Department of Energy’s Manufacturing Development Facility at Oak Ridge National Laboratory, displaying real-life examples of advanced AM applications, including the world’s first 3D printed excavator coming in at 12,000 pounds; and a wind blade whose core is printed from foam PLA and the skin is made from thermoset resin and fiberglass.

- Print-A-Drink — The AMT ETC featured “Print-A-Drink,” the world’s first 3D printing technology for drinkable liquids. The process uses a high-end industrial robot to accurately inject microliter drops of edible liquid into a cocktail.

- Insider Access — The forum had a full schedule of breakout sessions, from qualifications and standards to new 3D printers. A highlight for me was a presentation about DMG Mori’s new Lasertec 30 SLM machine and asking questions about their new noncontact recoater and adaptive beam control technologies.

- Stories — Sometimes you just had to be there. The amount of experience and knowledge held by the people at Formnext events is unparalleled, and nearly everyone is willing to share. Elementum 3D gave a talk about how they’ve improved their process for developing new 3D printable materials. One of the main lessons was being willing to experiment, backed by a story about trying to 3D print thermite on one of their machines.

- Making Connections — With a focus on the individual, Formnext Forum Austin stands out as an event that gave every attendee a chance to contribute as we shape the AM industrial community or the “Formnext fAMily,” as the event touts.

Related Content

Assonic Develops Automated System for Processing Reactive Metal Powders Without Gas Loss

Formnext 2024: The Assonic SPC 500 system features a closed circuit for conveying both powder and gas to eliminate gas loss while processing reactive metal powders in additive manufacturing.

Read MoreMeet The Cool Parts Showcase Winners

The Cool Parts Showcase winners for 2023 were announced at Formnext Forum Austin. Watch the award presentation here.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read More10 Video Reports From Formnext 2023

Our Formnext video playlist: Stephanie Hendrixson and Peter Zelinski report on various technologies seen at Formnext 2023 in brief videos they filmed at the show.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More