Creating Designs That 3D Printing Experts Love

3D printing can create virtually any shape imaginable, but that doesn’t mean it will be easy to print. How to design parts that are printable as well as functional.

3D printing technology has the somewhat deserved reputation of being able to create virtually any shape a designer’s mind can conjure up. That’s sort of correct, but not entirely. The hard part is coming up with aesthetically beautiful designs that also are functional for the application, structurally sound to achieve longevity, and are modeled to address the limitations of the medium. That takes some forethought and requires knowledge of how various materials work under different conditions. It’s possible to do a lot with 3D printing, and if you take these eight factors into consideration, you’re on course to create designs that 3D printing experts love to see.

1. Holes and Channels: New Shapes for Negative Space

3D printing has been around in concept since 1945, and functionally since 1971. Usable CNC machining arrived in the 1940s, and to go super-historical, the drill has been around for centuries. Why does all that matter? Because when designers include channels in their parts, they often forget that these features don’t have to be bound to the shape of a simple round hole. With 3D printing, holes and channels can be any shape that provides proper support for the build.

Think of Roman architecture and the need for a keystone to hold up an arch to help avoid the pull of gravity. Keeping this in mind, would a round channel be better served by a cross section shaped like a diamond (a square on its end), a circular hole with a vertical rib for smaller diameter channels, a teardrop, or even an upside-down heart? These are all functional, strong design shapes possible with 3D printing.

2. The Importance of Interior Radii

Parts that look sharp shouldn’t necessarily have sharp edges. In fact, with 3D printed parts, it’s better to look smooth. Whenever possible, use interior radii for edges and corners. That smooth contour not only has a great look, but it has the benefit of relieving the stresses that build up during the printing process. Aim to include organic curves in designs for 3D printing. Also, avoid sudden changes in part thickness which may result in parts that have shift lines.

3. Support for 3D Printed Parts

Gravity is good. It keeps us plastered to the Earth so we don’t lose our place in grocery store lines. But gravity is a definite factor when it comes to 3D printed parts. A thick part that includes a bend will not print well with a downfacing surface that is less than 45 degrees (in other words, flatter — less vertical). The lower the angle, the more aggressive and undesirable stair-stepping will be. In these situations, it’s more likely that the downfacing surface will require support structure to prevent sag and/or collapse. So, remember the 45-degree rule and the manufacturer will know you know what you’re doing.

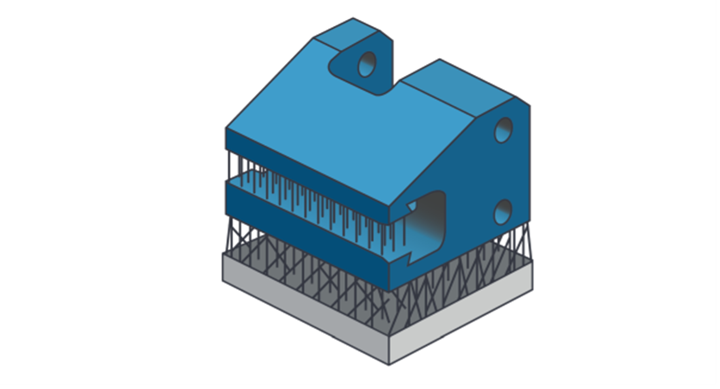

Downfacing surfaces less than 45 degrees most likely require support structures that will need to be removed later. Supports might also be added under the part to raise it off the build platform as seen here.

4. Simplify the Assembly

One of the coolest things about 3D printing is that it is only limited by engineering/design knowledge, the material, and the printing process chosen (Protolabs offers six of them). Rather than using hardware or other techniques to merge multiple small parts into an assembly, rethink the design as a single, large 3D printed part. The key to making this work is not to take 10 designs and crush them together into one CAD file. Instead, treat the new fused assembly as a single, novel part and rethink which features are valuable, and which aren’t.

A key here is working with a manufacturer with the capability and capacity to print large-format parts. For example, we have several GE X Line 2000R printers that have a maximum print volume of 800 by 400 by 500 mm (31.5 by 16 by 20 inches) and print in aluminum and Inconel. It’s amazing to watch these monster machines print one massive part that was once designed as a group of small ones.

Single large parts that include nice transitions between what used to be individual parts show that the designer did the homework in considering additive manufacturing processes — and often looks great.

5. Small Parts with Tiny Features

On the other side of the spectrum are small parts. There are certain 3D printing processes and materials that simply can’t handle extremely fine details, so designing parts with the understanding of those limitations is ultra-important. Stereolithography (SLA) is a notable exception and with a high-resolution thermoset resin like MicroFine, you can incorporate features as small as 0.0025" (0.0635 mm). Again, this requires advanced planning and willingness to accept limitations in size and color.

6. Bridging Distances

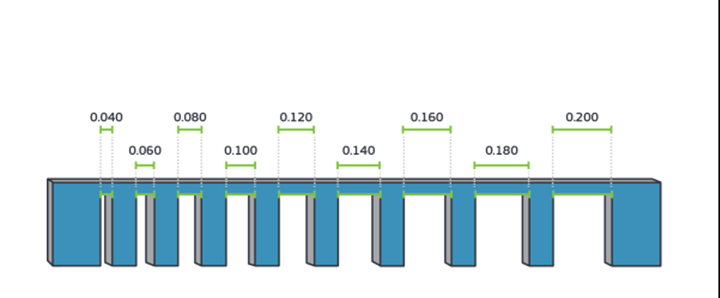

Like relationship longevity, the stronger and closer the support system, the longer lasting the part. If a 3D printed part has a long horizontal component to it, it needs to be designed with the structure to support it. Breakups are less likely when the space between pillars is designed to keep the part structurally sound. With direct metal laser sintering (DMLS), keep spaces 0.079 inch (2 mm) or less apart.

The space between pillars has a role in a part’s longevity. For the direct metal laser sintering process, keep bridges to less than 0.079 inch (2 mm).

7. The Dangers of Designing Thin Walls

As mentioned before, in design thin often looks cool, sleek and streamlined. But thin walls look awful when they crack off during end-use. If thin walls are needed for DMLS parts, use the 40:1 rule of height-to-wall thickness. If a wall is 0.1 inch (2.54 mm) thick, then the wall height shouldn’t be more than 4 inches (101.6 mm) to ensure structural integrity. However, that 40:1 rule can be stretched a bit if the wall is more naturally self-stabilizing, like the wall of cylinder.

8. Keeping the Customer Satisfied

Let’s face it. Every company’s primary goal is to please its customers. It’s during the design phase that many of the fundamental decisions that will delight a customer are made. Parts that are poorly designed for 3D printing won’t get the love (and financial support) you crave from your customers.

About the Author

Eric Utley

Eric Utley is an applications engineer at Protolabs with more than five years of experience in rapid prototyping and additive manufacturing. His focus is on stereolithography, selective laser sintering and direct metal laser sintering technologies, and he provides guidance to engineers on designing for manufacturability. Utley regularly consults with product development professionals from a range of industries including medical, consumer products, aerospace and automotive. He graduated from North Carolina State University with a Bachelor of Science degree.

Related Content

3D Printed Spacer Grids for Nuclear Power: The Cool Parts Show #79

Westinghouse Electric Company is exploring laser powder bed fusion as a means of manufacturing spacer grids, critical parts of the fuel rod assemblies used in pressurized water reactors.

Read MoreMicro Robot Gripper 3D Printed All at Once, No Assembly Required: The Cool Parts Show #59

Fine control over laser powder bed fusion achieves precise spacing between adjoining moving surfaces. The Cool Parts Show looks at micro 3D printing of metal for moving components made in one piece.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MorePreassembled Turbojet Engine, 3D Printed in One Build: The Cool Parts Show #75

Turbojet engines typically consist of hundreds or thousands of parts, but this engine — 2023 winner of The Cool Parts Showcase for Best Proof of Concept — was 3D printed as just two pieces, with the monolithic rotor embedded inside the stationary engine shell.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More