Co-Innovating the Future of Industrial Additive Manufacturing

Siemens’ recent additive manufacturing (AM) influencer tour to Hannover Messe in Germany not only highlighted how the company’s software solution provides capabilities to industrialize AM in a single integrated system, but also demonstrated that it needs a global AM network to co-innovate the future.

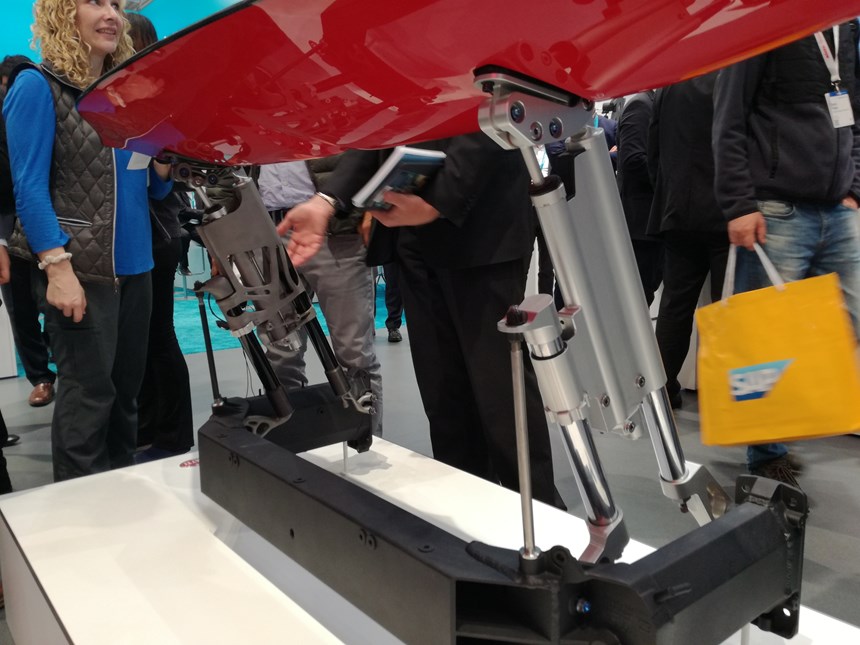

Why show a rear wing of a Bugatti supercar at the Siemens PLM booth at the world’s biggest industrial show, Hannover Messe? One would assume that one of the world’s fastest and most expensive road cars is already perfectly designed—considering it is powered by a roaring 1,500 hp and reaches speeds as fast as 450 km/hr. while at the same time staying on the ground (for comparison, a Boeing 747 takes off at 280 km/hr.). Consequently, the aerodynamics control system has to be very sophisticated and efficient. And it is. The rear wing adjusts its height and angle depending on the speed and makes sure the car is decelerated from its high speeds with a force of 0.4 G, resulting in forces ranging to 600 kg acting on the wing and the components carrying it.

But even a working system can always be further optimized to increase overall performance, which is what Siemens together with its project partners Bugatti, Fraunhofer, East-4D and Vogt Engineering were illustrating by showcasing reimagination using additive technologies, additive design and additive thinking.

If You Can Dream, It You Can Print It

The engineers have created what they say is the world’s largest hybrid functional assembly, based on bionic 3D-printed hollow and thin-walled titanium metal components and wound ceramic-coated, high-modulus carbon-fiber tubes (see Figure 5). The bionic structure reduces aerodynamic drag and is 50 percent lighter than the original design. And the complete process, from engineering, design and simulation to postprocessing and validation was done in one system, Siemens NX. Highlighting what Siemens calls the “One Integrated Solution” is what the presentation of Bugatti’s aerodynamic control system at the Hannover fair was all about.

...an uncontrolled workflow...is the biggest barrier today to industrialize AM.

While in the past, designers and engineers had to use several software systems to design, simulate and then postprocess and prepare the part for 3D printing, Siemens NX supports the full AM process-thread, using one data format for CAD/CAE/CAM and one user interface. According to Andreas Saar, additive manufacturing initiative leader at Siemens PLM, an uncontrolled workflow, where design software, simulation software and print preparation software, through to the AM process, heat treatment, finishing, inspection and the end-use part form a disconnected process chain, is the biggest barrier today to industrialize AM. Multiple file conversions and an uncontrolled workflow do not ensure the traceability and reproducibility we need to industrialize 3D printing, he pointed out during a presentation in Hannover. “The goal has to be the automation and digitalization of the entire end-to-end process,” he says. “Today we are using a high-technology laser metal melting process, for instance, and then fall back to low-tech hammer and chisel manual removal of support structures.”

And this is where the Bugatti comes into play again: Surely these parts exhibited at the show will not go into series production (who can afford a $1.5 million car?), but the clever bionic design of these 3D-printed component illustrates what is possible today, and possible to create using just one system, which will surely help to accelerate the industrialization of 3D printing. “We have to inspire engineers of what’s possible,” Prof. Claus Emmelmann, CEO of Fraunhofer IAPT, said during his presentation in Hannover. ”The IP is not in the production, it is in the design and the materials.”

Vision: One Integrated End-To-End System

Siemens’ vision is an integrated end-to-end system where every process step is connected by a digital thread, driven by digital twins, connected to data management and the shop floor as well as to production software, MES systems and ERP.

Fully operational serial production utilizing a digital end-to-end software chain has already proven that industrialization of AM works. Siemens says it was an early adopter of selective laser melting (SLM) AM technology and has successfully scaled its production.

“The conventional design was made of 13 parts and 18 welds and the lead time was 26 weeks. Now we have one integrated part and three weeks’ lead time.”

In the small town of Finspang, Sweden, for instance, Siemens produces industrial gas turbines with outputs of up to 54 mW. Components for these are and will increasingly be 3D-printed in this shop, where more than 20 AM machines are connected in fully operational serial production, producing end-use parts including a water pump impeller which is already in use at the nuclear power plant in Krsko, Slovenia, as well as SGT-700/SGT-800 burner fronts, which will be in serial production and commercial operation in 2018. "Burner manufacturing by means of SLM offers flexibility, completely new designs, shorter lead times and an improved life time," Vladimir Navrotsky, CTO, Siemens Distributed Generation Service Business Unit, explains. "The conventional design was made of 13 parts and 18 welds and the lead time was 26 weeks. Now we have one integrated part and three weeks’ lead time."

The team has also developed an optimal lattice structure for creating a mixture of natural gas and hydrogen in the burner. "For some Siemens customers, hydrogen is a cheap alternative to natural gas because it’s produced as a byproduct of chemical processes," Navrotsky explains, “which prompted us to modify the SGT-800 burner." Now it’s possible to use up to 60 percent hydrogen, resulting in annual savings of more than 3 million euros compared with running the turbine on natural gas. There are specific design solutions for other fuels as well.

In Worcester, UK, Siemens has invested 27 million euros in a new state-of-the-art production facility to support the industrialization of AM. The Siemens Business, Materials Solutions, currently runs 17 EOS machines producing prototypes and small series parts made of “difficult-to-weld” nickel superalloys and other alloys. The company is currently working on a new building with a capacity to host 60 machines and plans to expand into the United States.

In Germany, Toolcraft is running Trumpf, EOS and Concept Laser machines and has realized a digital process chain that is consistent and traceable for all process steps, which is very important as the company manufactures aerospace parts and is NADCAP certified for nondestructive testing (NDT). “Introducing one software, Siemens NX, enabled us to get rid of isolated 3D printers and four different software packages with numerous interfaces and formats,” says CEO Christoph Hauck. “We work closely together with our partners including Siemens, which is paramount for our success.”

Speeding Up Leveraging the Potential of AM

All companies involved in the Siemens tour were clear about one thing: Without a global partner ecosystem it is not possible to industrialize AM.

Software developers, technology providers, consultants and end users need to collectively grow the market and not necessarily compete. Growing the pie together ensures that everyone gets a decent piece of the pie, says Güngor Kara from EOS. “The market is at a point where there are going to be a lot of winners and losers over the next 5 to 10 years. We want to grow the market and even sell our products like our materials to competitors and help companies to get into AM production through consultancy.”

Siemens aims to do the same and has initiated an AM network strategy to make additive manufacturing globally accessible. “We are developing a network which is open for everyone, connecting machine vendors, part buyers, material vendors, print shops, engineering consulting companies and software vendors,” explains Robert Meshel, strategy director, head of the AM network initiative at Siemens PLM. “Users can search for and connect with AM suppliers around the world, search for materials and experts such as application consultants, material experts or production engineers, and explore what applications are available such as an AM scheduler, cost calculator, labeling, parts nesting and much more.”

Related Content

Implicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreUser-Friendly Mass Spectrometry Tool to Enable AM

The Massbox is a technology designed to simplify mass spectrometry by bypassing the need to send samples to the lab for characterization and testing purposes. Exum Instruments’ debut tool is suitable for AM as it can assist with quality assurance, material characterization and failure analysis.

Read MoreCarnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.

Read MoreRobot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

Read MoreRead Next

Video: Industrializing Additive Manufacturing for Automotive

A number of components for the Bugatti Chiron sports car spoiler were reimagined for additive manufacturing, unleashing several performance improvements.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More