When to Use Additive Manufacturing? One Part Begins the Path

Identifying the right part to begin your AM path can demonstrate and validate the AM workflow, provide a benchmark for future work and more.

I can’t believe I am writing this column given what I wrote last month.

In case you missed it, I argued that reproducing an existing part “as is” with additive manufacturing (AM) generates very little upside. Rather, it will invariably cost you more to get the same performance out of AM, a tough sell to any boss. Granted, such a process substitution, or direct part substitution as it is often called in the AM community, may give you a speed advantage, but if you can’t convert that into a lead-time advantage of some sort, then the schedule benefit is moot as you’ve already designed, analyzed, tested, and produced the part. There is no upside to shortening the product development cycle for a part that already exists! Nonetheless, this is often where established firms start their AM journey, and I wanted to provide some guidance if/when you are forced to do the same.

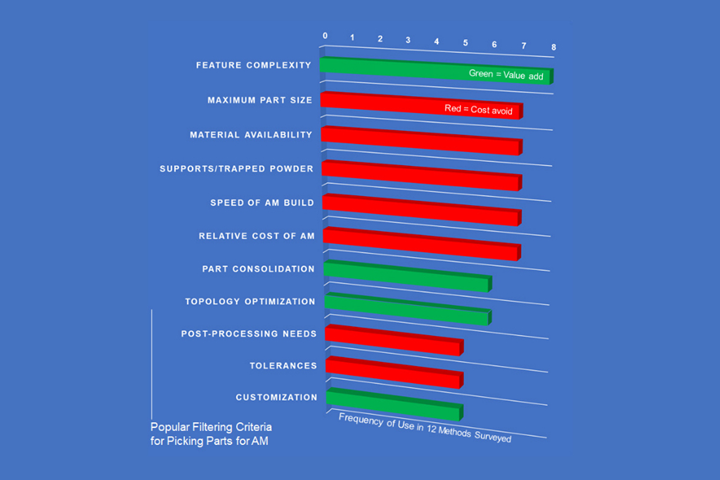

Most frequently used criteria for picking parts for AM based on a recent review of a dozen AM part filtering/screening methods. Photo Credit: Tim Simpson and Jen Bracken, Penn State

Part Geometry

Based on a recent review of a dozen methods for picking parts for AM, it turns out that the most common criterion for selecting parts for AM is part complexity, specifically, geometric features that make it difficult or challenging to fabricate a part via conventional means.

This should come as no surprise as the complex molds and tooling, multiple set-ups and fixtures, complicated cores and patterns, etc. will drive costs up and make the part expensive to provide using “traditional” methods. Given the potential to make more complex features more easily with AM means this is often a good place to start looking, but it by no means guarantees success. More complex geometries often translates into more support structures and post-processing when working with metal AM processes, and this drives costs up even further.

While complexity does not guarantee a good part for AM, I will say that the converse is always true. If the part is relatively simple, easy to produce by other means, requires few set-ups, and does not need any specialized tooling or fixturing, then you automatically know that it is NOT a good part for AM. You will not be able to make it cheaper with AM, and you will never beat the price of standardized and common-off-the-shelf components, metal or plastic, with AM given the technology available today. Granted, cost isn’t the only driver to consider, and sometimes learning or validating the AM workflow is worth the investment.

Materials

The next thing to keep in mind is that AM still remains limited in terms of (1) the commercially available materials that can be processed with AM and (2) the size of the parts that can be made by AM machines in the market. So, not surprisingly, material and part size are the second two most frequently used criteria when picking parts for AM.

While countless new materials are in development for AM, there are still only about 50 polymers and roughly 20 metallic alloys that are readily available for AM. Everyone is actively trying to change that, but the fact remains that commercially available materials remain limited for AM. If you don’t believe me, then I invite you to search the Senvol Database, which is free and updated regularly.

Build Envelope

Similar to limited materials, the build envelope — the volume that can be 3D printed — is still constrained to roughly 1 ft3 on the vast majority of laser powder fusion systems, for instance. Companies like 3D Systems, Additive Industries, Big Metal Additive, GE Additive, Relativity Space, SLM Solutions, and Velo3D, among others are pushing the build envelope for metal AM technologies, but you will pay a premium for these systems. On the polymer side, Cincinnati’s Big Area Additive Manufacturing (BAAM) system still leads the size race as hardly anyone can compete with their 20 ft x 7.5 ft x 6 ft build volume and 80lb/hr deposition rate that their system offers.

So if the part is relatively complex, fits on an AM machine, and is made from an available material, have you found your part to find your path and launch your AM journey? Maybe, but now is when you start considering things like the cost of AM, the build speed, the need for supports, trapped powder — the next set of criteria that are most frequently used for screening parts for AM. After that, people often consider part consolidation and topology optimization next, after which post-processing, tolerances, and customization are factored into the decision.

That rounds out the top 10 criteria for picking an AM part (ok, 11 for you Spinal Tap fans out there), but you can see why this does not guarantee success. Only four of these criteria (feature complexity, part consolidation, topology optimization, and customization) fall into the value-add category when designing for AM, but if you are constrained to make the part “as is”, then this value can’t be captured. To make matters worse, you may not even have the freedom to apply any cost-avoidance measures at the start of your AM journey — a double whammy right out of the gate.

Luckily, there are a few situations where you can turn this to your advantage as we will discuss next month. In situations where you can’t, finding a reasonable “pathfinder” part can still be beneficial. It can help you demonstrate or validate the AM workflow internally or with external suppliers, it can provide a benchmark or baseline for your future redesign efforts, and it can start to help de-risk the technology and gain the necessary insight into an AM process to achieve the performance and productivity gains that drive AM’s hype. More importantly, it can help people overcome their fears (e.g., are AM parts strong enough?) and even get them excited about AM technology, which puts you on the path to do more with your next AM part.

Read Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More