Are AM Parts as Strong as Those Made Conventionally?

An additively manufactured flight-critical helicopter part indicates that they are.

The last few months, I have been focusing on several of the safety concerns related to using metallic powder feedstocks in additive manufacturing (AM), including inhalation risks, safe powder handling and pyrophoric hazards. While these concerns may have scared off some of you, it is important that everyone understand all aspects of AM as it gains industry acceptance. Too many stories just focus on the power and potential of AM, creating unrealistic expectations and fairytale scenarios.

This month, however, I want to return to discussing the benefits of AM and share a case study we have been involved with in the Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D) at Penn State. As the co-director of CIMP-3D, I help give tours to the more than 1,000 people that visit each year to see firsthand our powder-bed fusion, directed energy deposition, hybrid manufacturing and computed tomography (CT) scanning capabilities. We field a lot of questions during those tours, and the most frequently asked one is: Are AM parts as strong as the same part made using a conventional manufacturing process?

For years, we had to reference data, studies and experiments comparing properties of AM-made parts with traditionally made parts. Now, we simply hold up a link and bracket assembly additively built from titanium and explain how these two parts helped secure the engines on a helicopter—and not just any helicopter, but one of the Navy’s MV-22B Ospreys.

The MV-22B Osprey link and fitting assembly is one of CIMP-3D’s recent manufacturing demonstration projects, and it could be considered one of the more significant projects in the AM industry, because it was the first flight-critical component manufactured additively to be used on a military airframe. (Read more about its first flight.)

My colleague, Dr. Edward (Ted) Reutzel, led the CIMP-3D team on this project, working closely with the Naval Air Systems Command (NAVAIR) headquarters in Patuxent River, Maryland, the Naval Air Warfare Center (Lakehurst, New Jersey) and other NAVAIR organizations. Ted and his team helped perform build-orientation and layout studies for the components, characterize distortion and build quality, and support final build design for production. The effort also included comprehensive powder characterization, post-build material characterization, thermomechanical build simulation of components and builds, and evaluation of dimensional measurements through various stages of postprocessing (such as before and after heat treatment, and part removal).

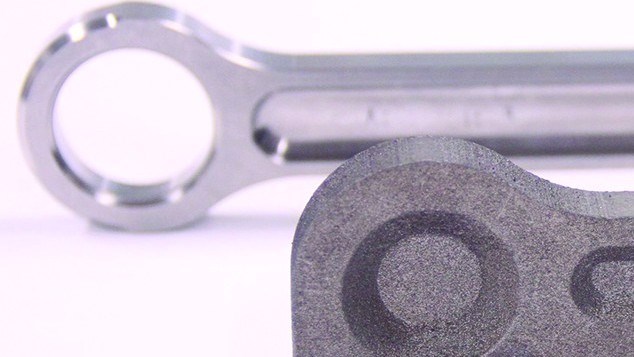

You often don’t get to the see the before and after shots of an AM part, but I have included images of the parts on the build plate (Figure 1) and of the link “as built” (Figure 2). These images should help you better appreciate the complexity of the build (multiple links, fittings, witness coupons and other test specimens on a single plate), the amount of powder that needs to be removed, and the extent of the machining and finishing that needs to occur to create an exact replica of the original, traditionally built parts.

(Those interested in reading more about the postprocessing and the testing that the AM parts underwent to ensure they were as good as the original can check out the recent paper by NAVAIR’s J.M. Kasprzak, A.B. Lass and C.E. Miller titled “Development, Test, and Evaluation of Additively Manufactured Flight Critical Aircraft Components.”)

So an additively built part can be as strong as a conventionally built part. But why choose AM? In this case, it was not about cost or performance so much as validation that an AM part could be approved as a direct replacement for a conventionally made part for flight demonstration—a first for the Navy. Given that, the potential benefit is speed, as AM shows promise in providing the ability to source parts quicker or make replacement parts in the field instead of waiting for them to be delivered. In this way, AM can improve logistics by providing spares and repairs more quickly than with a direct part replacement.

Finally, I want to express how incredibly proud we are of the work performed by Ted and his team, which spanned about 18 months. As you can imagine, it was a very stressful project, and I often joke that, while I’m glad CIMP-3D was involved, I’m also glad that I wasn’t on Ted’s team. My team and I were working on a much less stressful project with a broader timeline to improve the design of a piston crown. More on that next month.

This article originally appeared in Additive Insights, a monthly column in Modern Machine Shop magazine.

Related Content

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read More“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More