3D Printing for Aerospace

Already the aerospace industry has adopted additive manufacturing (AM) for training devices and end-use parts. AM enables lighter weight, more fuel efficient and easier-to-manufacture parts for aircraft and spacecraft. Stay competitive in the evolving space market — CW Tech Days: New Space Applications by sister brand CompositesWorld addresses manufacturing for space, with special emphasis on composite materials. Be a part of it on November 13, 2024.

ESSENTIAL READING

VIEW ALLMission Critical: An AM Breakthrough in Commercial Aviation

The GE9X is the first commercial aircraft engine to reach production with significant additive content. The story of GE’s accomplishment and why it matters.

Read MoreVideo: Safety Is No. 1 in Metal AM

John Murray of Concept Laser discusses safety, quality and automation as they relate to additive manufacturing for production metal parts.

WatchSlideshow: Inside the New Honeywell AM Facility for Reactive Metals

Seven machines currently committed to aluminum expand the company’s capacity to 3D print both tooling and parts. One of the photos illustrates a safety measure addressing reactive metals.

Read MoreVideo: Step by Step AM for Aerospace

A short video from Pratt & Whitney outlines the steps necessary to take a metal AM part from design to installation.

WatchHear UL’s Recorded Webinar about Training and Certification in Additive Manufacturing

Personnel development will be an important prerequisite for the advance of AM. Christopher Krampitz discusses the skills and knowledge necessary in this webinar.

Read MoreVideo: The Additive Nozzle’s Origin Story

The LEAP engine fuel nozzle is likely additive’s greatest success in part production so far, but it wasn’t always clear that the nozzle could be made this way. This video from GE Aviation tells the story.

WatchLatest Aerospace News And Updates

JuggerBot 3D Chooses Research Partners for Air Force Large-Format Hybrid Additive Manufacturing Project

Oak Ridge National Laboratory and Mississippi State University’s Advanced Composite Institute have been selected to assist in the research and technical development of production workflows using thermoplastic and thermoset deposition.

Read MoreEndeavor 3D Earns International Traffic in Arms Registration

Endeavor 3D strengthens its technology capabilities and operational systems to better support the U.S. defense industrial base as well as energy and supply chain manufacturing services.

Read MoreAirtech and Ascent Aerospace Collaborate to Promote Additive Manufacturing Tooling in Aerospace, Defense

By combining Airtech’s high-performance materials and Ascent’s production capabilities, the companies aim to support the adoption of polymer composite additive tooling to some of the most demanding applications and customers in the world.

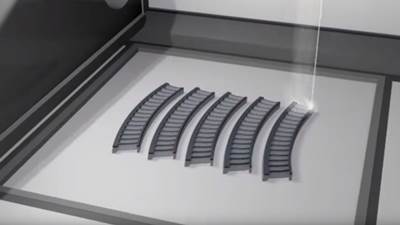

Read MoreAM Materials Consortium Selects Partners for LPBF Fabrication and Testing

The consortium is developing open LPBF parameter sets to streamline machine, material and process qualification, with the goal of expediting customers’ process development leading to serial production.

Read MoreAmerica Makes Names 2024 Ambassador Award Winners

The Ambassador Award Program recognizes individuals who have continually demonstrated outstanding dedication to advancing America Makes and its mission to innovate and accelerate additive manufacturing to increase the nation’s global manufacturing competitiveness.

Read MoreSupernova Creates Defense and Space Business Unit to Develop 3D Printing of Military-Grade Energetic Materials

Target applications for the new business unit include solid rocket motors which are critical components for the next-generation hypersonic platforms.

Read MoreFeatured Posts

Video: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

WatchAdditive Manufacturing at NASA (Part 2): AM Radio #52

In this follow-up podcast episode on additive manufacturing at NASA, Dr. Tim Simpson joins us to discuss how the organization thinks about AM overall, and its role in advancing additive alongside and in service of commercial industry.

ListenAdditive Manufacturing at NASA (Part 1): AM Radio #51

In this first episode of a two-part special on additive manufacturing at NASA, we discuss three specific 3D printed parts for upcoming missions and share observations about the organization’s approach to AM.

ListenFeatured Media

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

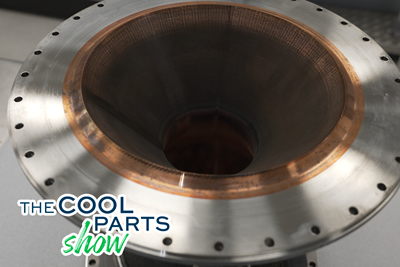

Watch3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

WatchCryogenic Tanks for Space Refueling: The Cool Parts Show All Access

NASA's Paul Gradl describes an important application of AM beyond the spacecraft itself: refueling the spacecraft. Directed energy deposition offers the most practical way to produce aluminum tanks to keep fuel supercool.

WatchFAQ: Aerospace

Why is additive manufacturing an ideal option for aerospace training devices?

High-fidelity trainers need to be as close to the actual aircraft as possible, so they’re often made using salvaged aircraft parts. There is currently a low useable inventory of salvaged parts. These are low-volume, one-off parts, which is a strength of additive manufacturing. Read more here.

How can additive manufacturing benefit space exploration?

Because additive manufacturing is continuously progressing in material adoption and end-use application, its benefits to almost every industry, including space exploration, are potentially endless. Here are two examples:

AM can assist with getting vehicles to space by providing weight reduction and improved performance to complex parts such as thrusters and engines.

Printing spare parts in space is another benefit, alleviating supply chain and inventory challenges.

Click here for more benefits and to see a part that was 3D printed on the International Space Station.

What are examples of AM impacting the aerospace supply chain?

- An airline used 3D printed molds to cast covers for aircraft engines while the planes were docked during the height of the Covid pandemic and engine covers were difficult to source.

- Metal AM is used to provide fast turnaround, customization and complexity to aircraft repair parts, including integrally built rotors or “blisks.”