A Spin on Additive Manufacturing

A DMLS system from EOS enables Kappius Components to make design changes to their bike hub while experiencing reduced lead time and improved material strength.

One barrier to entrepreneurial success is finding an efficient and cost-effective route from idea to physical product. After designing a bike hub/assembly, Russ Kappius, developer at Kappius Components, needed a way to make design changes while getting new parts to customers quickly. Direct laser metal sintering (DMLS) technology from EOS improved design freedom, reduced lead time and increased material strength.

Kappius Components (Littleton, Colorado) began in 2008 when Mr. Kappius, a mountain-bike enthusiast, decided he could get more speed and responsiveness from bicycle hubs. He began working out a design for a novel oversized hub and high-performance drive assembly that would transfer more power from pedal to chain to wheel. After securing a patent, he began looking for a way to fabricate the parts.

He first knocked on the door of a fabricator that offered waterjet cutting. While waterjet could cut extremely hard metals, the process was limited in its capacity to produce dimensionally accurate and complex parts, Mr. Kappius says. Next, he tried wire EDM because it could cut intricate shapes in hardened steel. This method produced parts that met specifications, but it had a fairly long turnaround time and could fabricate only 2.5D geometries—a constraint to his components’ shapes. Yet, with no better option available at the time, he settled for this technique.

For 2 years, Mr. Kappius and his son, Brady, field-tested versions of their hub and tweaked its design. “Because we’re a startup, we quickly learned that we needed to make design changes and get new parts out to our customers fast,” the elder Mr. Kappius says. “We had to leverage our time to market to stay competitive.”

In late 2011, Mr. Kappius discovered DMLS, an additive manufacturing technology that met rapid turnaround needs and enabled the company to produce parts to exacting specifications. It also allowed for additional design complexity. He also located Harbec—an Ontario, New York-based DMLS provider—and sent them a CAD file that included the latest round of design refinements.

About 30 days later, the father-son team received the new parts. Within the first week of field testing, the elder Kappius won a race using the latest hub assembly. “We went from concept to bike-ready components in about a month,” he says. “I’ve never been able to move that quickly before.”

DMLS technology has accelerated the speed of improvements—a key benefit, given the fact that the hubs have been through a half-dozen design iterations since Kappius Components opened its doors. The elder Mr. Kappius says that DMLS provides the flexibility to make changes at any time. “It allows me to make small design changes and almost immediately test them on the bike. That’s the beauty of the technology,” he says.

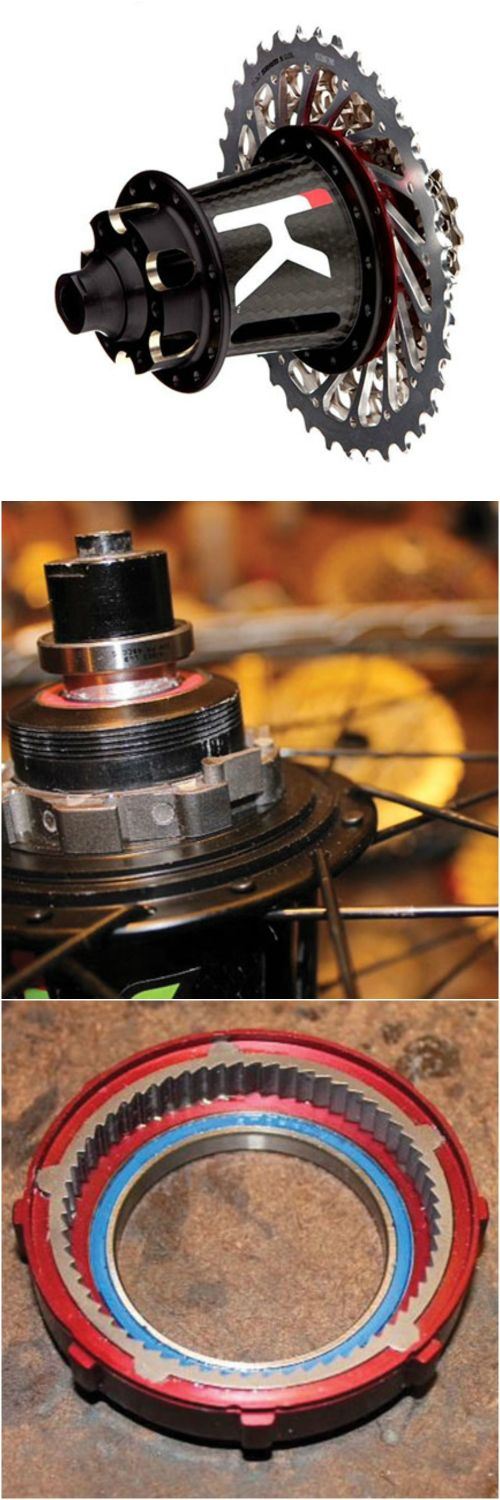

The beauty of the lightweight, yet durable hub, on the other hand, comes from the sleek carbon-fiber shell (handmade by the younger Mr. Kappius), as well as the drive assembly housed inside it. The assembly is made of three major parts: an outer drive ring, an inner ring with 60 teeth, and eight pawls (or flippers), which engage in pairs with teeth on the inner ring. This setup functions like a ratchet, allowing forward motion while preventing backward motion. The large size and additional points of engagement compared to standard designs are the key features that provide the heart of the hub’s intellectual property and allow a cyclist to translate the act of pedaling into increased drive force.

When he first geared up for business, Mr. Kappius bought ready-made pawls and engineered the rest of his system around them. Once he discovered laser sintering, he was able to redesign the pawl itself and add a 1-mm cylindrical basal extension, which positioned them better when they engaged.

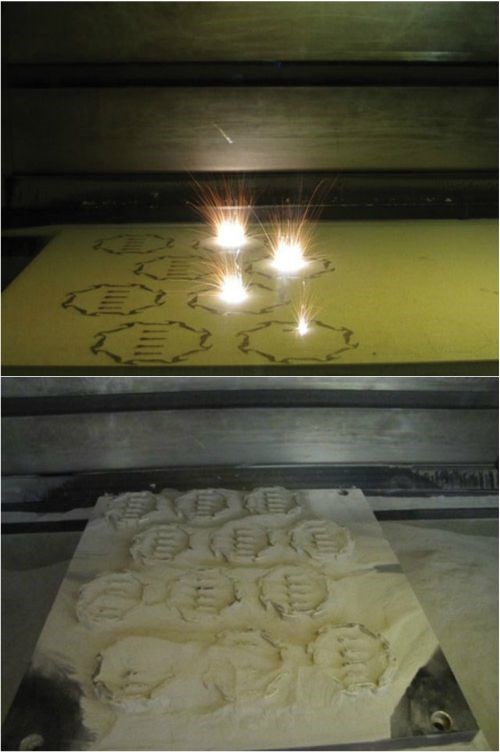

Laser sintering’s advantage over other fabrication methods is the ease with which it can manufacture cylindrical and other irregularly shaped parts, like the pawls, Mr. Kappius says. As an additive rather than subtractive process, the technology “grows” parts layer by layer using powdered materials, such as metals, polymers and foundry sands, which are heated and melted by a laser. The laser beam follows the outlines and contours of a series of cross-sectional slices taken from a 3D digital model.

“There is no way we could have improved our pawl design using wire EDM because that method cuts parts out of flat pieces of metal,” Mr. Kappius says. “DMLS has freed us to make improvements on all of the elements in the system.”

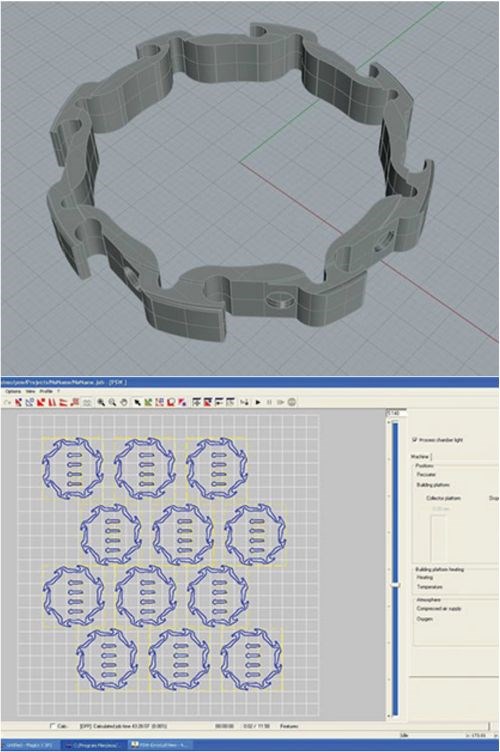

At subcontractor Harbec, where Kappius components are manufactured, Keith Schneider and Jeremiah Wackerman are in charge of the laser-sintering operation. A typical order of 10 drivetrain assemblies requires two builds on Harbec’s EOSINT M 270 from EOS (Novi, Michigan). Experienced operators working with manufacturing software arrange the components on the machine’s build platform to maximize output. The job consists of 10 outer rings, 10 inner rings, and 80 pawls (eight for each assembly), plus a few extras.

Because durability was a prime concern for the application, Mr. Kappius selected maraging steel—a heat-treatable metal with excellent hardness and strength—from the available materials. Run time is around 25 hours per plate, or 50 hours total for the 10 assemblies.

Following the run, the parts are removed from the laser-sintering unit, machined and heat-treated—all in-house. On a CNC mill, the manufacturing support structures are removed and an extra 0.020 of material, which was added to the back side of the part during manufacturing, is planed down to create a machined finish. “We use this approach when parts have moving interfaces, such as in this hub or with bearings and bushings,” Mr. Wackerman says. “It gives us a really clean surface without imperfections.” The components are then moved to Harbec’s kiln and hardened to 52 HRc. “The tool steel is super strong,” Mr. Kappius says. “I haven’t had a single hub failure.”

Harbec supplies the parts on an as-needed basis, and the father-son team assembles the components in their home shop to be shipped around the world. Production is accelerating fast for the young company—it sold about 100 hub assemblies this past year and is projecting sales of 500 in 2014.

Related Content

How Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreQuadrus: Powder Management Tactics for Tungsten Rhenium and Other AM Alloys

The expert in additive manufacturing of high-value parts for the Defense Department often must change from one exotic material to another in its powder bed machines. Cleaning is a core competency. Here are lessons of this company’s system for working with an ever-changing mix of 3D printed alloys.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More