Reshoring, Tooling, Sustainability and More: Top 10 Stories of 2021: AM Radio Episode #9B

Reviewing our most-viewed stories of the year revealed some of the topics that have been top-of-mind for additive manufacturers. Read or listen to the countdown.

Share

Despite the setbacks of the COVID-19 pandemic, restrictions on travel, supply chain disruptions and more, additive manufacturing (AM) continued to advance throughout 2021. While these challenges hindered additive users and technology providers in some ways, they also highlighted for OEMs, business leaders, governments and others the potential good that 3D printing technology can bring — for rapid and bridge production, for reshoring, for more sustainable manufacturing.

At the end of 2021, we’ve decided to look back at our top 10 most-viewed stories published this year. The full list (with links) is published below; I also discussed each one with Julia Hider in a recent episode of the AM Radio podcast, which you can find embedded below as well. In reviewing this list, we found evidence of some of the trends above, the ones you might expect, like applications geared toward circular economy goals and reshoring stories. But we also discovered a few surprises, like the ongoing and compelling use of 3D printing for tooling applications. Read on or listen for more.

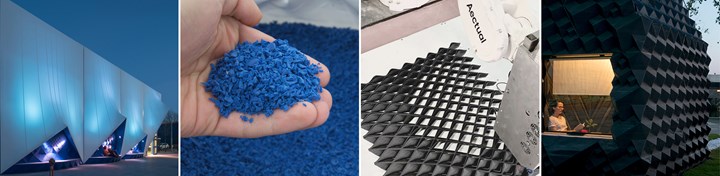

10. For Sustainable 3D Printed Architecture Think Renewable, Not Permanent

The design choices of today won’t be the trends of tomorrow. Dutch company Aectual chooses to embrace changing tastes by making it easy to procure and recycle 3D printed architectural elements.

Why it matters: We saw increased interest in 3D printing as a means of achieving sustainability and circularity goals, plus more use of this technology in the building, construction and architecture spaces.

Recycling on a large scale: The facade for a temporary EU building in Amsterdam was created by Aectual’s parent Dus Architects. When no longer needed, the facade was ground into pellets, mixed, colored and 3D printed by Aectual into new products including the “tiny house” seen on the far right. Photo Credit: Aectual

9. 3D Printed Battery Electrodes Could Drive Electric Vehicles Forward

Precise control of battery electrode architecture through photopolymerization opens the door to new cell geometries and lighter battery packs for EVs and more, Photocentric says.

Why it matters: Better battery manufacturing is one way 3D printing is enabling more energy efficient next-generation transportation technology.

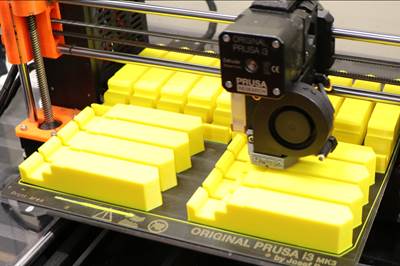

8. 10 Examples of 3D-Printed Tooling

Additive manufacturing can aid conventional manufacturing through the production of tooling. This article showcases 10 clever uses of 3D-printed tooling.

Why it matters: Tooling (anything used to form, hold or assist in manufacturing some end-use component) continues to be an important application for 3D printing, and one that spans an impressive range of industries and businesses.

7. Lightweight Combustion Chamber for 3D Printed Rocket Engine: The Cool Parts Show #30

An engine for repeated trips to the moon is 3D printed in just three pieces from a metal matrix composite combining aluminum for weight saving with ceramic for high-temperature performance.

Why it matters: Assembly consolidation and new material possibilities advance the places where additive makes sense, and AM parts are proving critical to various space flights and missions.

Masten’s combustion chamber for the Broadsword engine is indicative of other trends in space technology — lightweighting, fuel efficiency, and reusable spacecraft. We featured this part on The Cool Parts Show.

6. How 3D Printing Will Change Composites Manufacturing

Peter Zelinski conducts a Q&A with Jeff Sloan, editor-in-chief of CompositesWorld, to explore tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Why it matters: 3D printing is bringing new possibilities for material layup, composite molds and much more, and making it feasible for composite parts to replace those that have been machined from metal or made in some other conventional way.

5. More Than Meets the Eye to Cobra’s 3D Printed Putter

Cobra Golf drew attention in November 2020 with the launch of a limited-edition putter with metal 3D printed head. The club has something to say about product development, reshoring manufacturing and the future of consumer goods.

Why it matters: The supply chain disruptions that affected business in 2020 did not stop in 2021 and show signs of continuing. 3D printing offers a potential solution for production that can be done closer to home.

4. How Flowable Metal Paste Could Deliver on 3D Printing's Promise for Mold Tooling

A new 3D printing process that shapes extruded metal paste before sintering can produce fine detail and surface finish suitable for injection mold cores and cavities with limited or no additional postprocessing.

Why it matters: A process that consolidates the steps to arrive at a finished metal part promises faster leadtimes for mold tooling — but also a potential avenue to other kinds of metal parts.

This mold for a medical device made with the TrueShape process required no surface finishing before being used for production injection molding. Photo Credit: Mantle

3. Establishing a Process for 3D Printing Carbide

Using its experience making pressed and sintered carbide parts, Hyperion Materials & Technologies developed a new material, printing processes and sintering cycles for 3D printed carbide.

Why it matters: Additive manufacturing forms the material at the same time as the part, which opens new opportunities to process materials like carbide that have otherwise been difficult to work with.

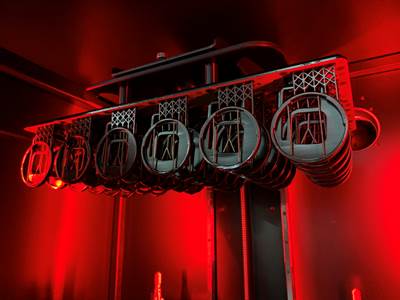

2. After Years in China, 3D Printing Lets Vacuum Accessory Maker Develop U.S. Production

The costs of injection molding had Dustless Technologies making tooling and many parts offshore. Additive manufacturing promises an alternative, as in the case of the company's newest product, which is entirely U.S.-made.

Why it matters: A move toward 3D printing allows for a shift away from mold tooling and all the restrictions it places on manufacturing. Bringing AM in house offers freedoms in terms of reduced time to market, new geometric possibilities and rapid iteration — plus new sources of revenue (see below).

Implementing AM is allowing Dustless Technologies to reshore manufacturing of production components — and also make parts like this for external customers, through a new arm called Merit3D.

1. Ford is Saving Millions through 3D Printing (But Maybe Not How You Think)

Two longtime workers at Ford’s Sharonville Transmission Plant near Cincinnati grew tired of experiencing the delays and downtime resulting from expensive and hard-to-get replacement parts. The solution? Learn additive manufacturing and save the company time and money.

Why it matters: 3D printed tooling fills niches that otherwise would be occupied by “close enough” solutions or no tool at all. The ability to rapidly develop and produce just the right tool has potentially huge implications for an OEM’s bottom line.

Listen to the podcast above for our conversation on these top 10 stories!

Related Content

-

Castor Publishes Sustainability in Additive Manufacturing Trends Report

New research from Castor indicates manufacturers can reduce tons of carbon emissions with 3D printing.

-

OnAdditive Offers Aftermarket Upgrade for 3ntr A2, A4 3D Printers

The enhanced capabilities include a new control system that gives the printers increased printing speeds, improved quality, automatic bed leveling and various other user-centric improvements.

-

Siemens’ Partnerships Work to Accelerate Scaling of Additive Manufacturing Technologies

Formnext 2024: Siemens is focusing on collaborations that emphasize the importance of innovation and open, interoperable technologies to facilitate the integration of additive manufacturing into conventional manufacturing technologies.

Related Content

Castor Publishes Sustainability in Additive Manufacturing Trends Report

New research from Castor indicates manufacturers can reduce tons of carbon emissions with 3D printing.

Read MoreOnAdditive Offers Aftermarket Upgrade for 3ntr A2, A4 3D Printers

The enhanced capabilities include a new control system that gives the printers increased printing speeds, improved quality, automatic bed leveling and various other user-centric improvements.

Read MoreSiemens’ Partnerships Work to Accelerate Scaling of Additive Manufacturing Technologies

Formnext 2024: Siemens is focusing on collaborations that emphasize the importance of innovation and open, interoperable technologies to facilitate the integration of additive manufacturing into conventional manufacturing technologies.

Read MoreSustainable Metal Powder Company Addresses Next Piece of Road Map: Renewable Energy

Continuum Powders, the material production arm of small-scale foundry technology company MolyWorks, has announced new partnerships aimed at further reducing the environmental impact of its metal powder production.

Read MoreRead Next

After Years in China, 3D Printing Lets Vacuum Accessory Maker Develop U.S. Production

The costs of injection molding had Dustless Technologies making tooling and many parts offshore. Additive manufacturing promises an alternative, as in the case of the company's newest product, which is entirely U.S.-made.

Read MoreFord is Saving Millions through 3D Printing (But Maybe Not How You Think)

Two longtime workers at Ford’s Sharonville Transmission Plant near Cincinnati grew tired of experiencing the delays and downtime resulting from expensive and hard-to-get replacement parts. The solution? Learn additive manufacturing and save the company time and money.

Read More10 Examples of 3D Printed Tooling

Additive manufacturing can aid conventional manufacturing through the production of tooling. This article showcases 10 clever uses of 3D printed tooling.

Read More

.jpg;width=70;height=70;mode=crop)