Materials

MC Machinery’s Wire-Laser Metal 3D Printer for Efficient, Versatile Processing

The printer applications include rapid prototyping, mold and die, one-offs, short runs, mass manufacturing, maintenance, repair, tooling and more.

Read MoreSustainability in Additive Manufacturing Is a Moving Target: AM Radio #37

Assessing 3D printing as a sustainable manufacturing method is a complex problem. Dr. Tim Simpson and Stephanie Hendrixson discuss current research and future opportunities on AM Radio.

Listen3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

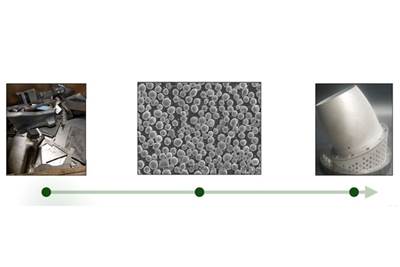

WatchPowderCleanse Concept Delivers In Situ Powder Analysis for Metal 3D Printing

A collaborative project developed a prototype solution for measuring particle size distribution on the production floor, as part of the sieving step typical to additive manufacturing processes using metal powders.

Read MoreNexa3D QLS 820 High-Throughput Laser Sintering Platform

This high-throughput thermoplastic production system combines ultrafast printing with open materials and cloud-based software platform to deliver production volumes much greater than other powder-bed solutions on the market.

Read MoreZeda Collaborates With AddUp for Aerospace, Medical Additive Manufacturing

The first of eight AddUp FormUp 350 powder bed fusion machines deployed has been installed at Zeda to support its growth in the aerospace and medical sectors.

Read MoreVolkmann’s PowTReX Rolls to 3D Printers for Easy Installation, Movement

The metal powder transfer and recovery system now features a mobility package as standard, making it easier for companies to automate the powder transfer, extraction and sieving processes at multiple printers without investing in multiple machines.

Read MoreSenvol Commercializes Siemens Energy’s Material Databases

Databases for Ti64, Inconel 625 and Inconel 718 were generated by Siemens Energy on its laser powder bed fusion machines. Although the data was initially intended exclusively for internal use, the company recently decided to make the data commercially available.

Read MoreNexa3D Expands Resin Portfolio With Ceramic, Flexible, Clear Materials

Nexa3D worked with material experts at BASF and Henkel to validate custom formulations for its ultrafast fleet of industrial and desktop 3D printers.

Read More8 Transformations 3D Printing Is Making Possible

Additive manufacturing changes every space it touches; progress can be tracked by looking for moments of transformation. Here are 8 places where 3D printing is enabling transformative change.

Watch