Vericut’s Version 9.2 Features More Optimization Options

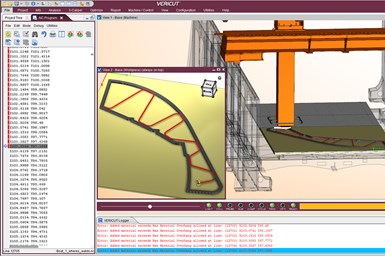

RAPID 2021: Simulation software verifies key additive functions and makes it easy to identify errors, excessive material overhangs, voids and misplaced material.

Thermwood overhang error

CGTech’s Vericut version 9.2 includes enhancements to collision checking and overall performance, more options for optimization on subtractive machining operations, enhancements to reports and more, the company says.

Vericut can simulate both additive and traditional machining (milling or turning) capabilities of new hybrid CNC machines. The simulation is said to verify key additive functions (power settings, material feed versus machine feed rates and more), and makes it easy to identify errors, excessive material overhangs, voids and misplaced material.

Vericut’s additive module also works with Force for additive NC simulation, verification and optimization on hybrid machines for metal additive manufacturing (AM) and machined parts. The software gives users the freedom to arrange additive and machining operations in any order, checking that all setups and holding fixtures work while verifying that the finished part matches the intended design.

The company says that giving the additive simulation software increased simulation and collision checking speed is designed to protect CNC AM equipment. It is said this enables customers to build parts in new and creative ways, and make critical determinations about when those new additive methods will succeed or fail, and thereby give them savings in both time and materials.

Related Content

-

Semiconductors, Tungsten, AM Affordability and More from Formnext 2024: AM Radio #56

The trade show included increased applications for the semiconductor market, machine launches and technology advances aimed at cost cutting, plenty of LFAM and more. Listen to our conversation on Formnext 2024.

-

The Top 10 Additive Manufacturing Stories of 2024

Defense, space exploration, thermal management — these are some of the topics that captured the Additive Manufacturing audience’s interest in 2024. But there’s also an overarching theme: Don't wait for additive manufacturing to be perfect. Instead, leverage the applications perfect for AM.

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.