Ultimaker 5.0 Cura Enables Finer, Faster Prints

The software’s enhanced slicing engine is said to enable thinner walls and finer details in additive manufacturing.

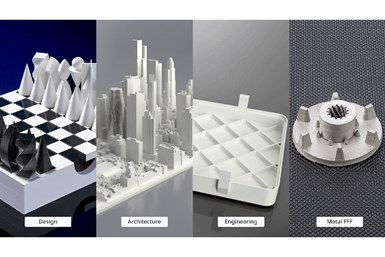

Ultimaker Cura 5.0 software’s enhanced slicing engine is said to enable thinner walls and finer details in additive manufacturing, enabling new applications. Photo Credit: Ultimaker

Ultimaker has launched beta testing for Ultimaker Cura 5.0, the latest version of its free, open source, slicing software which is said to enable unique applications in design, architecture, engineering and metal 3D printing.

The software is said to include an enhanced slicing engine that sets a threshold for finer and faster 3D prints. The newly developed variable line width capability of this slicing engine is said to improve its ability to print thin walls and fine details, and parts printed with this engine will also be stronger. Other improvements include faster print profiles for owners of Ultimaker printers, support for Apple M1 chips, and more.

The slicing engine in the software enables the use of variable line width when slicing a 3D model. Previously, the line width used when slicing a file was decided by the diameter of the nozzle and the line width settings used. Once chosen and sliced, the line width would be consistent throughout the part. This means that if part of a print was two-and-a-half lines thick, two lines would be used, and a small gap would be left between them. Small details of less than one line thick would not be printed at all.

This has been a common shortfall for fused filament fabrication (FFF) 3D printing in general and Ultimaker Cura 5.0 is said to solve that. With the new, improved slicing engine, the width of lines are instead increased and decreased to create the most efficient tool patch and to most accurately print fine details. It is said the result is fewer gaps on the inside of parts and better quality when printing thin walls and fine details.

The variable line width capabilities of the new slicing engine in Ultimaker Cura 5.0 also result in fewer gaps on the inside of printed parts. This means parts are more solid and, therefore, stronger. The biggest improvement in strength will be seen when printing thin walls where fixed line width would previously have resulted in walls with internal gaps and, in some cases, walls that would not print correctly at all.

It is said the improved printing of thin walls brings parts printed with the software closer than ever to the strength and quality of those produced using injection molding.

In addition, print profiles available to users of Ultimaker printers have been updated to make use of the improved capabilities of the software, resulting in print time reductions of up to 20%.

Related Content

-

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

-

7 Things We Saw at Formnext 2024 — Video Playlist

There were countless processes, applications and announcements at Formnext 2024. Here are seven standouts Peter Zelinski and Stephanie Hendrixson caught on film.

-

Carnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.