Smart Layer Software Automates Visual Monitoring for Additive Manufacturing

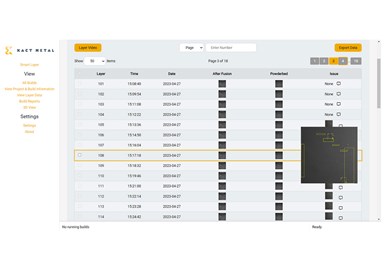

Smart Layer software conducts a layer-by-layer analysis using computer vision algorithms and convolutional neural networks, then provides anomaly detection in real-time.

Xact Metal’s Smart Layer software solution provides automated visual monitoring and real-time analysis of laser metal powder bed printers. The Smart Layer software is an intelligent monitoring solution designed for metal additive manufacturing (AM).

The software conducts a layer-by-layer analysis using computer vision algorithms and convolutional neural networks, then provides anomaly detection in real-time. Smart Layer immediately notifies the operator upon issue detection time to prevent print failures.

Xact Metal partnered with Addiguru to build the foundation of Smart Layer. Addiguru provides in-situ monitoring technology for AM processes. Part anomalies can occur during the printing process that are difficult for the operator to detect manually and, when uncaught, may necessitate costly post-build inspection and repair. Addiguru says it recognizes and is committed to fulfilling the need for a robust real-time defect detection tool for the rapidly growing 3D printing market.

“We are excited to introduce Smart Layer monitoring,” says Juan Mario Gomez, CEO of Xact Metal. “Addiguru’s open policy has allowed us to easily integrate our technologies to provide even more value to the end user. Our focus at Xact Metal is not only to make metal additive manufacturing affordable but also easy to use. Smart Layer complements this mission by using intelligent tools to verify the integrity of each print, one layer at a time.”

Addiguru is pleased with the work on the Smart Layer solution. “Using advanced imaging technology, Smart Layer identifies typical issues such as part swelling, streaks, hops and spatter on the print bed,” says Shuchi “SK” Khurana, president and CEO of Addiguru. “Since their foundation six years ago, Xact Metal has focused on increasing the adoption of metal 3D printing technology and we are glad that Smart Layer can support abundant printing experiences and this mission.”

- Learn about Xact Metal’s XM300G 3D printers for large quantities and large parts. The series comes in single-, dual- or quad-independent laser system models with 100% overlapping print zones that are said to offer industrial speed and performance.

- Read about Xact Metal’s high-performing dental solution. The complete dental solution includes Xact Metal’s XM200G printer, a full software workflow in partnership with Materialise’s Pre-Print Dental Module, and certified dental powder from Bego Medical.

Related Content

-

How Avid Product Development Creates Efficiencies in High-Mix, Low-Volume Additive Manufacturing

Contract manufacturer Avid Product Development (a Lubrizol company) has developed strategies to streamline part production through 3D printing so its engineering team can focus on development, design, assembly and other services.

-

Video: 3D Printed Tooling Eases Cobot Integration

At NPE 2024, Universal Robots and EMI Corporation highlighted how 3D printed end effectors, fixtures and more enable adoption of collaborative robots.

-

UltiMaker Targets Light Industrial Applications With 3D Printer Designed for the Factory Floor

The company’s Factor 4 3D printer introduced this week is designed to complement conventional manufacturing equipment including CNC machining and automation.