Materialise Software Module Optimizes Data and Build Preparation for Metal LPBF

The e-Stage for Metal+ software uses physics-based modeling to improve automated support structure generation for laser powder bed fusion.

Share

Read Next

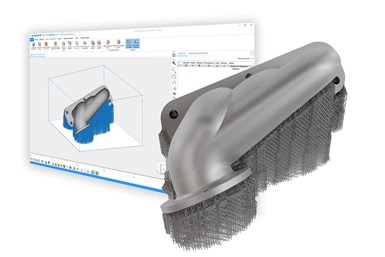

By automating support structure generation with Materialise’s software, additive manufacturers can streamline the 3D printing process. Source: Materialise

Materialise’s e-Stage for Metal+ software optimizes data and build preparation for laser powder bed fusion (LPBF) systems using physics-based modeling to automate the support structure generation. The solution is designed to help make metal additive manufacturing (AM) more economically viable.

LPBF is one of the leading segments for AM and may also be one of the most complex technologies to use, the company says. According to an independent survey commissioned by Materialise, two main factors holding companies back from adopting 3D printing are a lack of knowledge and the cost associated with the production process. Both challenges play a central role during build preparation for LPBF.

“By automating support structure generation with Materialise’s software, you can streamline your 3D printing process,” says Mirco Schöpf, EOS product line manager software. “It simplifies support removal, reduces support volume up to 80%, eases powder extraction and decreases build plate machining after an effortless part removal. We look forward to exploring e-Stage for Metal+ and discovering additional benefits.”

The software utilizes physics-based modeling to calculate where deformations during the 3D printing process will occur and automatically generates needle-thin and cone supports where needed. Combining the two support types optimizes stability and heat distribution during the 3D printing process, helping to avoid part deformation while reducing postprocessing efforts. This is said to eliminate the compromise between part quality and overall production costs, making the AM process more economically viable and straightforward to adopt. Automated tools such as e-Stage for Metal+ lower the learning curve, enabling users to connect the software to any machine and quickly optimize support generation.

“Metal AM users tend to overload parts with support structures during manual data preparation,” says Ian O'Loughlin, metal practice lead at Materialise. “They want to avoid defects and the costs associated with reprinting the parts. That’s why intelligent tools like e-Stage for Metal+ are crucial. Automating support structure generation at the sweet spot of printability and required supports saves time, material and postprocessing costs.”

The e-Stage for Metal+ software is a module for Magics, Materialise’s data and build preparation software, and core element of its 3D Print Suite. Magics is a technology-neutral software offering compatibility with nearly all import file formats and connectivity to all major 3D printing technologies. It provides users with advanced control and automation for their workflows.

“We are continuously enhancing our software solutions to support AM users in their daily business,” says Lieve Boeykens, solution strategist at Materialise. “Automation can support AM users in bridging knowledge gaps to adopt the technology faster, accelerating return-on-investment and helping them lower the overall production cost. Materialise’s e-Stage for Metal+ helps companies achieve economic viability.”

Related Content

-

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

-

Decentralized Manufacturing Network Aims to Make 3D Printers a Shared Global Resource

The 3DOS additive manufacturing network will let OEMs and creators take advantage of open 3D printer capacity anywhere in the world.

-

Hybrid Additive Manufacturing Improves Debarking Knife Tip Strength and Production Efficiency

Nicholson Manufacturing chose the Mastercam APlus specialized add-on to unlock hybrid manufacturing for making its debarker knife tips, enabling it to add durable layers to the wear surfaces of the tips to make them more resilient while also making the production process more efficient.