Markforged’s Performance Advisor Accelerates, Simplifies Part Simulation

Markforged’s Performance Advisor technology is use-case independent while being able to fully automate and optimize the performance of a part.

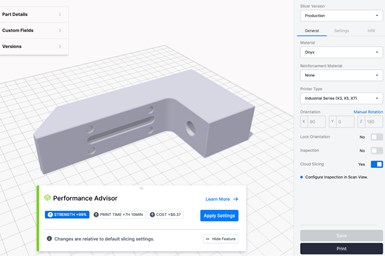

Performance Advisor offers a physics-based analysis method that addresses the challenge of doing structural analysis without a use case. Source: Markforged

Markforged has added a Performance Advisor feature to its Eiger software, giving users a faster, simpler way to automatically simulate parts to make them stronger. The feature enables users to create stronger, more robust parts while maintaining a balance with material and print time efficiency — automatically and without any user input. The company says the feature builds on Markforged’s Simulation tool to take the guesswork out of 3D printing.

Simulation usually requires a known use case — how the part will be loaded and how it interacts with other objects when it is in service — which is often unknown. To address this challenge, Markforged’s technology is use-case independent while being able to fully automate and optimize the performance of a part.

Unlike traditional tools that might need specialized expertise and time-consuming analysis, this technology is powered by machine learning and operates with the click of a button. It’s a method of analyzing part performance to recommend print settings that result in a strong part that is manufactured efficiently — a part that balances strength improvements with minimal increases in cost and print time

The company says that manufacturers who don’t know CAD can use it, and it reduces the stress of having to be a structural analyst or go through trial-and-error. Customers can use the Simulation tool to explore how changes in print settings impact part performance, and optimize for cost and print time.

The process is fully automated. No user input is needed to generate the results. After users save a part in Eiger, Performance Advisor will automatically analyze the part and recommend print settings that, relative to the default settings, improve the strength while keeping material cost and print time low. Users can then decide if the performance improvement is worth the added cost and print time. Users can apply the recommended settings with one-click or ignore them and proceed with the Eiger workflow.

This physics-based analysis method addresses the challenge of doing structural analysis without a use case. In lieu of defining a use case, the shapes in which a part naturally vibrates (the eigenmodes) of the part geometry are used to explore the impact of print settings on part performance.

Computing the lowest energy eigenmode is the first step. The second step is to run a machine learning driven optimization procedure that scores print settings using three variables — strength, material cost and print time. Print settings that score high in strength and low in cost and print time are considered optimal. These configurations are what Performance Advisor aims to recommend.

The company says the capabilities of Performance Advisor will grow over time. For the initial release, important limitations are:

- Onyx is the only supported material.

- Wall Layers and Roof and Floor Layers are the only print settings adjusted.

- The Fill Pattern is Triangular and the default Fill Density is held constant.

- Performance Advisor may not be able to analyze parts with extremely complex STL meshes.

Related Content

7 Things We Saw at Formnext 2024 — Video Playlist

There were countless processes, applications and announcements at Formnext 2024. Here are seven standouts Peter Zelinski and Stephanie Hendrixson caught on film.

Read MoreCarnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.

Read MoreOvercoming the Bottleneck to Customized Manufacturing: Quoting

Spokbee’s software-as-a-service platform is shaving months off of the quoting and pricing process for 3D printed and other types of configurable products.

Read More3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More