Incus Hammer Lab35 Offers Economic Protoyping, Small-Scale Production

Metal 3D printer has potential to increase performance and reduce costs for small and mid-scale production, as well as manufacture parts featuring complex geometries.

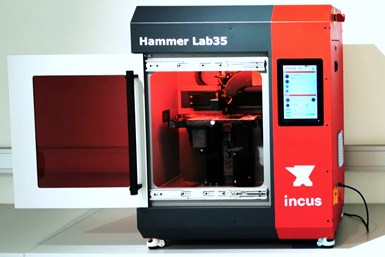

Hammer Lab35 3D metal printer

The Incus Hammer Lab35 metal 3D printer is capable of printing intricate geometries for functional prototypes and pre-series manufacturing. It utilizes the lithography-based metal manufacturing (LMM) process developed by Incus to provide economic prototyping and small-scale production using metal injection molding (MIM).

According to the company, the Incus LMM process technology and its flagship series machine, Hammer Lab35, give manufacturers superior feature resolution, surface aesthetics and mechanical properties for part sizes <200 g —a combination achieved for the first time in metal AM. With a print speed of up to 100 cm3/hr. and a lateral resolution of 35 µm, the Hammer Lab35 printing solution is designed to deliver the best quality parts. The company says the process can be easily integrated into existing MIM production lines or research and development departments as an option for small-scale production and prototyping.

Two Hammer Lab35 machines are in operation at the Institute for Precious and Technology Metals at Pforzheim University and its spin-off company, Metshape. With this collaboration, the process and system are reviewed and tested, and new materials and applications are being developed. This valuable feedback helps Incus to adapt the machine and the feedstocks to the needs of the manufacturing industry, increasing performance and reducing costs for small and mid-scale production, as well as manufacturing parts featuring complex geometries.

Related Content

-

How Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

-

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

-

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.