Henkel Expands Loctite Range of Photopolymer Resins

Formnext 2023: The company provides a wide range of high-performance engineering-grade resins specifically designed for industrial applications, rapid prototyping to end-part production.

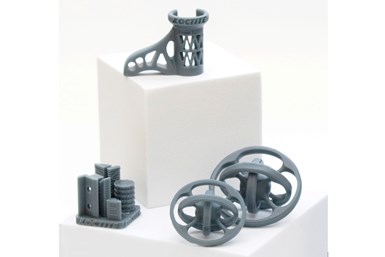

Henkel has expanded its portfolio of photopolymer resins for 3D Printing with four Loctite materials, offering performance and versatility. From rapid prototyping to end-part production, these products are designed to support a diverse range of applications.

The tough, industrial photopolymer resins include unique high impact-resistant 3D printing materials for durable, functional and production parts. The specialized resins are characterized by distinct and unique properties tailored to specific industrial or commercial applications.

Loctite 3D PRO9274 is a durable dark gray resin that enables fast printing of highly detailed parts. Designed to seamlessly print on various types of digital light processing (DLP)/liquid crystal display (LCD) printers, the material enables users to produce a broad range of products all at a cost-effective price point.

Loctite 3D IND3380 is a specialty resin with electrostatic dissipative (ESD) properties and a high heat deflection temperature (HDT) of 190°C that offers excellent stiffness, precision and versatility.

Loctite 3D IND5714 is a gray elastomer resin with high rebound properties and excellent repetitive strain resistance. A low shore hardness combined with excellent compression set, good tear resistance and strength makes this material well suited for use in industrial elastomeric, safe touch applications.

Loctite 3D MED9851 is a high-performance medical material with excellent tensile and flexural physical properties. Stiffness combined with toughness and its transparent appearance make this material well suited for an extensive variety of impact-resistant medical device applications.

“We are excited to introduce these additions to our product lineup,” says Dr. Daniel Adams, vice president at Henkel Loctite 3D Printing. “The new products represent an extension of every one of our product lines and thereby enable our customers to manufacture parts for an even wider range of industries, applications and use cases.”

The company provides a wide range of high-performance engineering-grade resins specifically designed for industrial applications. Designed for various DLP and LCD platforms, Loctite resins have the mechanical properties to support aerospace, automotive and transportation, industrial and manufacturing, medical and consumer goods applications. The Loctite line can support additive manufacturing at a production scale with a broad material portfolio, including properties such as high-impact, high-temperature resistance and even elastomeric.

- Read about Nexa3D working with material experts at BASF and Henkel to validate custom formulations for its ultrafast fleet of industrial and desktop 3D printers. Nexa3D expanded its resin portfolio with ceramic, flexible, clear materials.

- Learn about Henkel validating Loctite formulations on a Desktop Metal Xtreme 8K Machine. The workflow validations are said to provide complete specifications for printing, curing and cleaning parts printed with Loctite materials.

Related Content

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreConcept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More