Fabrisonic Smart Baseplate Measures Stress in PBF Builds

The baseplate with embedded sensors is designed to measure loads and monitor quality during PBF builds.

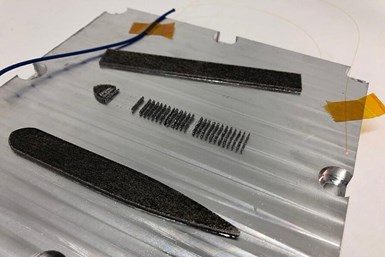

Fabrisonic Smart Baseplate. Photo Credit: Fabrisonic

Fabrisonic teamed with EWI — known for powder bed fusion (PBF) research — and Luna Innovations (fiber optic sensors) to design and build an instrumented PBF smart buildplate for the Defense Logistics Agency (DLA) under a Phase I STTR. The baseplate with embedded sensors is designed to measure loads and monitor quality during PBF builds.

The Smart Baseplate was developed to address issues such as parts debonding or delaminating from the buildplate during printing, which can be difficult to detect because the part is buried in powder.

Fabrisonic’s low-temperature Ultrasonic Additive Manufacturing (UAM) process utilizes ultrasonic welding to 3D print metal parts, including parts with embedded sensors. Fabrisonic used its solid-state 3D process to print a plate with a single, embedded fiber-optic sensor. The fiber optic was embedded with a specific undulating pattern that enables resolving the strain across the entire buildplate. The team put the smart baseplate in EWI’s PBF machine and attempted a build that included problematic features.

From the initial build, the team says it found the device picked up significantly more information than just bulk stress state. According to the team, resolution and scan rate were high enough to actually discern the scan strategy of each layer; defects showed up as large compressive strains forming early in the build at localized points; and slow delamination of a specific feature could be seen in the data although the recoater blade never hit the build.

Based on preliminary results, the team feels this approach could be used to monitor quality during PBF builds. For series production, data can be compared between a known good baseline and subsequent serial numbers. For low volume, build flaws can be identified as they happen, thereby enabling the operator to do a full abort, saving powder and machine time. And, for multipart builds, build flaws in a single part can be seen which enables the operator to abort that feature before it affects others.

Related Content

-

Formlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

-

The Robot Craftsman: Force Sensing and Vision Help Realize Automated AM Postprocessing (Includes Video)

Automated production via additive manufacturing will need automated postprocessing. This UK startup is equipping robots with the capabilities needed for critical, fine-detail finishing of metal 3D printed parts.

-

Video: 3D Printed Tooling Eases Cobot Integration

At NPE 2024, Universal Robots and EMI Corporation highlighted how 3D printed end effectors, fixtures and more enable adoption of collaborative robots.