EOS Integrates 1000 Kelvin’s AMAIZE AI Co-Pilot Into Software Suite to Accelerate Productivity and Engineering Speed for Additive Manufacturing

The AMAIZE AI “co-pilot” platform is designed to harness cutting-edge AI to streamline design processes, slash engineering costs and accelerate the introduction of new additive manufacturing products.

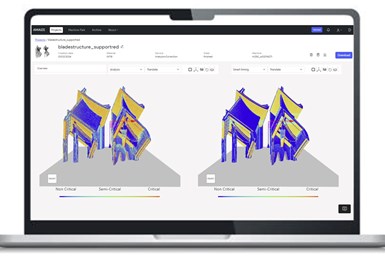

The AMAIZE AI software can predict near real-time print issues, perform corrections and generate an industrial-grade, ready-to-use print file specific to the user’s machine. Source: 1000 Kelvin

1000 Kelvin is working with EOS to integrate 1000 Kelvin’s AMAIZE AI co-pilot platform for additive manufacturing into the EOS software suite, helping to expedite production workflows and enhance the engineering process for customers worldwide.

With this integration, 1000 Kelvin empowers customers in industries such as aerospace, energy and contract manufacturing to harness cutting-edge AI, streamlining their design processes, slashing engineering costs by up to 80% and accelerating the introduction of new additive manufacturing (AM) products.

FKM, an additive manufacturing (AM) contract manufacturer in Europe and an early adopter of the integrated solution, reports marked improvements in engineering speed and product quality, achieving new heights in manufacturing excellence. “1000Kelvin's AMAIZE aligns perfectly with our commitment to digital excellence in manufacturing,” says Matthias Henkel, FKM CEO. “It allows our engineers to predictively navigate complex components’ quality and consistency requirements.”

AMAIZE’s AI predictive capabilities enable a shift from physical to digital iteration. “This is an important step forward to the industrialization of additive manufacturing,” says Martin Steuer, EOS’ SVP Software Division. “Coupled with its robust cybersecurity, AMAIZE represents a significant advancement in cloud-based solutions for the industry. We're pleased that EOS customers now have access to this value-added service within our open ecosystem platform and our EOS Developer Network Partner 1000 Kelvin.”

The integration with EOS software demonstrates the open architecture of EOS products and the extensive resources of the EOS Developer Network (EDN). “These factors have allowed us to seamlessly incorporate the EOSPRINT APIs into our platform, ensuring that our customers can effortlessly benefit from the combined strengths of our technologies,” says Omar Fergani, 1000 Kelvin CEO.

The AMAIZE software is the “AI co-pilot” for engineers, using AI models to predict print issues, perform corrections and generate print files specific to a machine. With AMAIZE, 1000 Kelvins says users can get prints right the first time. EOS users will be able to access AMAIZE directly by contacting 1000 Kelvin.

Related Content

-

Inspection Method to Increase Confidence in Laser Powder Bed Fusion

Researchers developed a machine learning framework for identifying flaws in 3D printed products using sensor data gathered simultaneously with production, saving time and money while maintaining comparable accuracy to traditional post-inspection. The approach, developed in partnership with aerospace and defense company RTX, utilizes a machine learning algorithm trained on CT scans to identify flaws in printed products.

-

NCDMM Enhances CORE Platform, Debuts Roadmapper 2.0 Data Tool

The CORE online platform helps members identify, access and utilize intellectual capital assets that align with the group’s Technology Development Roadmap, while Roadmapper 2.0 complements CORE, enabling the sharing of interactive, digital road maps.

-

Carnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.