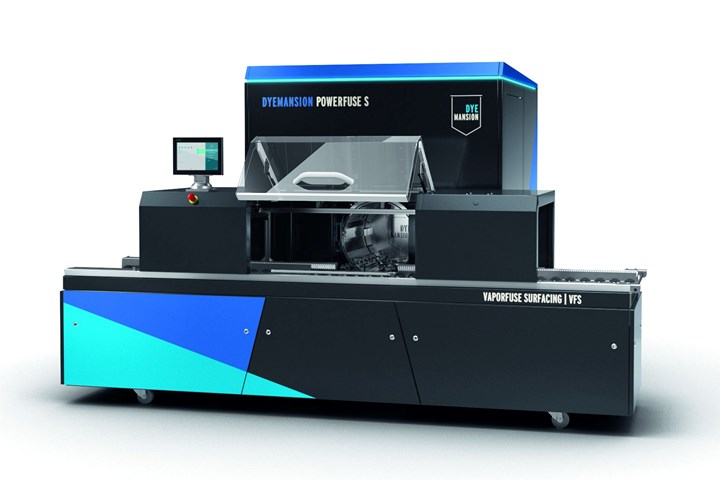

DyeMansion Powerfuse S Enables Improved Print-to-Product Workflow

RAPID 2020: DyeMansion’s Powerfuse S is Industry 4.0 ready and offers fully automatic loading, connectivity and batch tracking features.

Share

Read Next

DyeMansion PowerFuse S.

DyeMansion’s Powerfuse S, the system behind DyeMansion’s brand-new VaporFuse Surfacing process, is Industry 4.0 ready and offers fully automatic loading, connectivity and batch tracking features.

Operating the Powerfuse S does not require protective clothing against chemical hazards. Validated and specially developed programs for all common materials are available and ready to use. All process parameters can be adapted individually for other materials. This ensures flexibility and a seamless integration with existing production processes such as the DyeMansion Print-to-Product workflow.

VaporFuse Surfacing (VFS) delivers sealed and washable parts with injection molding like surfaces. The surface roughness is reduced to a minimum. The entire process chamber is flooded with vapor while undergoing vacuum, this ensures a reproducible processing of complex geometries and internal surfaces. VFS works for all common plastics and particularly for flexible polymers such as TPU. VFS enables a sustainable process without chemical waste.