Arburg Validates Mechnano’s Polycarbonate ESD

Mechnano’s PC ESD pellets can enable Arburg printer owners to fabricate static-dissipative parts with advanced properties.

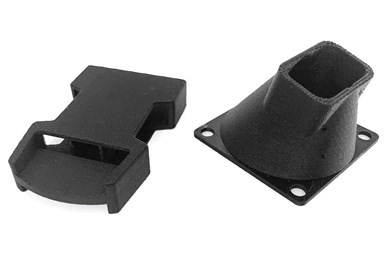

Arburg, a manufacturer of plastic processing machines, has successfully printed Mechnano’s Polycarbonate Thermoplastic pellets with static dissipative properties (PC ESD) on its Freeformer line of pellet extrusion additive manufacturing (AM) printers.

Through its discrete, dispersed and functionalized carbon nanotube technology, D’Func, Mechnano’s PC ESD pellets will enable Arburg printer owners to fabricate static-dissipative parts with advanced properties. This can open new doors for additive manufacturing, particularly in industries where ESD is of extreme importance in either the production process or final product.

“Mechnano is excited to simultaneously announce our release of PC ESD and its qualification on Arburg’s Freeformer printers. With Arburg’s global reach, PC ESD will be accessible to a wide user base,” says Bryce Keeler, Mechnano president. “The ability to additively produce functional components with ESD properties will create substantial advancements in the electronics manufacturing market, giving Arburg printer owners a competitive edge in prototyping and production speed.”

Mechnano’s proprietary technology, D’Func, detangles, separates and functionalizes carbon nanotubes (CNTs), then disperses them into the polycarbonate thermoplastic which is then pelletized to work on the Freeformer. Unlike other CNT-enhanced materials, Mechnano’s PC ESD pellets are unique in ensuring homogeneous electrical properties. Mechnano’s nano-engineered dispersions eliminate CNT agglomerations that yield inconsistent static dissipation, enabling 100% ESD coverage with precise ESD values (versus ranges) being achieved.

- Read this article to learn about Mechnano’s nano-uniform ESD, high-temperature 3D-printable resin. The resin for quick-turn soldering processes can help electronic manufacturing service providers reduce cycle time, increase throughput and ensure nano-uniform ESD protection.

- Here’s an article about Mechnano’s ESD photopolymer resin which offers enhanced impact resistance. The resin is well suited for parts that undergo a higher level of abuse where breakage would occur with more rigid solutions.

- Check out this product post about Arburg’s Freeformer 750-3X 3D which features more space inside the build chamber for larger components.

- Learn more about Arburg’s Freeformer Machines which produce complex, functional parts. The machines feature an open system enabling the properties of the additively manufactured parts to be specifically adapted.

Related Content

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

-

3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.