University of Maine Composites Center's 3D Printer Named World's Largest

The university now holds world records for the largest prototype polymer 3D printer, largest solid 3D-printed object and largest 3D-printed boat.

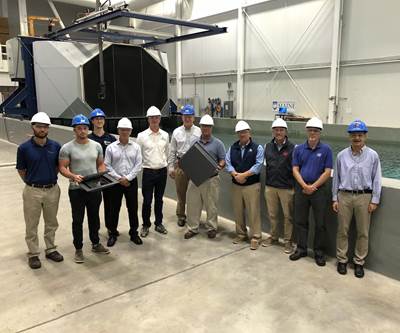

Photo Credit: the University of Maine’s Advanced Structures and Composites Center

The University of Maine’s Advanced Structures and Composites Center has been awarded three Guinness World Records for the world’s largest prototype polymer 3D printer, largest solid 3D-printed object and largest 3D-printed boat.

The event culminated with the world’s largest 25-foot, 5,000-pound 3D-printed boat, named 3Dirigo, being tested in the Alfond W2 Ocean Engineering Laboratory, an offshore model testing facility equipped with a high-performance wind machine over a multidirectional wave basin.

The new 3D printer is designed to print objects as long as 100 feet by 22 feet wide by 10 feet high, and can print at 500 pounds per hour. The university reports that the printer will support several initiatives, including development of bio-based feedstocks using cellulose derived from wood resources, and rapid prototyping of civilian, defense and infrastructure applications.

A $20 million research collaboration with Oak Ridge National Laboratory will support fundamental research in key technical areas in large-scale, bio-based additive manufacturing, UMaine says. The research will focus on cellulose nanofiber (CNF) production, drying, functionalization and compounding with thermoplastics, building on UMaine’s leadership in CNF technology and extrusion research. By placing CNF from wood into thermoplastics, bio-derived recyclable material systems can be developed with properties that may rival traditional materials, possibly even metals, the university says.

The 3Drigo 3D-printed boat, tested in the Alfond W2 Ocean Engineering Laboratory during the Oct. 10 event.

Bio-based feedstocks are recyclable and economical, providing competitive advantages for Maine’s manufacturing industries, including boatbuilding. In 2018, the UMaine Composites Center received $500,000 from the Maine Technology Institute (MTI) to form a technology cluster to help Maine boatbuilders explore how large-scale 3D printing using economical, wood-filled plastics can provide the industry with a competitive advantage. The cluster brings together the expertise of UMaine researchers and marine industry leaders to further develop and commercialize 3D printing to benefit boatbuilders in the state. By 3D printing plastics with 50% wood, boat molds and parts can be produced much faster and are more economical than today’s traditional methods, UMaine says.

Photo Credit: UMaine

To demonstrate the new printer’s capabilities, UMaine 3D printed a 25-foot patrol boat with a hull form developed by Navatek, a leader in ship design and a UMaine Composites Center industrial partner. The 5,000-pound boat was printed in 72 hours — from Thursday, September 19 to Sunday, September 22. The printer, with both additive and subtractive manufacturing capabilities, enables rapid prototyping for both defense and civilian applications. UMaine also showcased a 3D-printed, 12-foot-long U.S. Army communications shelter. The new printer will support programs with the U.S. Army Combat Capabilities Development Command (CCDC) Soldier Center and its mission to develop rapidly deployable shelter systems for soldiers. Other use areas include concealment applications, structural shelters and high-temperature fire retardant materials for vehicle-mounted shelters.

Working with the U.S. Army Corps of Engineers, UMaine plants to use the 3D printer to produce deployable, low-logistics infrastructure systems, including a 5,000-pound, 21-foot-long 3D-printed mold for a new 76-foot-long composites bridge girder. The girder has been licensed to a UMaine spinoff company, Advanced Infrastructure Technology, that is in the process of fabricating girders for a bridge to be constructed in Hampden, Maine in summer 2020. In addition, rapid production of stay-in-place concrete formwork is reportedly a potential solution for both infrastructure and coastal resiliency construction applications.

“The U.S. Army Corps of Engineers Engineer Research and Development Center (ERDC) is proud of the accomplishments achieved in the long-standing collaboration with University of Maine in military engineering,” says David Horner, director of the ERDC Information Technology Laboratory. “The large 3D printer capability will greatly support research in applications to both military engineering and national civil works infrastructure. This unique facility, along with applications of high-performance computing, will help advance the rapid-prototyping and additive manufacturing capability of DoD.”

“This 3D printer is an outgrowth of research we have been doing for 15 years in combining cellulosic nano and micro fibers with thermoplastic materials,” says Habib Dagher, executive director of UMaine’s Advanced Structures and Composites Center. “Our goal is to print with 50% wood products at 500 pounds per hour, and achieve properties similar to aluminum. We thank our congressional delegation for their support.”

Among the October 10 ceremony attendees were U.S. Sens. Susan Collins and Angus King, U.S. Rep. Jared Golden, officials from the Maine Governor’s Office, and leaders at the U.S. Army Combat Capabilities Development Command Soldier Center, U.S. Army Corps of Engineers, U.S. Department of Energy Advanced Manufacturing Office, Oak Ridge National Laboratory, the University of Maine and University of Maine System.

Related Content

PowderCleanse Concept Delivers In Situ Powder Analysis for Metal 3D Printing

A collaborative project developed a prototype solution for measuring particle size distribution on the production floor, as part of the sieving step typical to additive manufacturing processes using metal powders.

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read MoreRead Next

UMaine Composites Center receives $500,000 to help boat builders incorporate 3D printing technology

Technology cluster will help Maine boatbuilders explore how large-scale 3D printing with wood plastic composites can provide a competitive advantage.

Read MoreNew research collaboration to advance efforts to 3D print with wood products

The ORNL and UMaine research team will work with the forest products industry to produce new bio-based materials that will be conducive to 3D printing a variety of products.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More

.jpg;width=70;height=70;mode=crop)