MT Aerospace Expands Services With AddUp PBF Technology

MT Aerospace says its FormUp 350 machines have proven their ability to produce highly complex parts, such as heat exchangers, with an unrivalled surface finish.

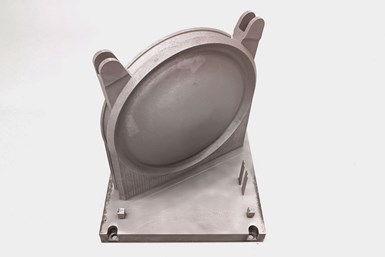

Baffle for DED-PBF hybrid satellite tank component manufactured by MT Aerospace on a FormUp 350 machine. Source: AddUp

MT Aerospace and AddUp have been partners since 2020, working to industrialize metal additive manufacturing (AM) in Europe. Now, with the addition of two FormUp 350 PBF machines loaded with titanium and aluminum powder, MT Aerospace further extends the range of services it can offer to industrial customers, especially in the aerospace, space, defense, automotive and energy sectors.

These two PBF machines join the two Modulo 400 DED machines already operated by MT Aerospace for development and qualification of satellite fuel tanks, in collaboration with the European Space Agency.

“MT Aerospace's FormUp 350 machines have proved their ability to produce highly complex parts, for example heat exchangers, with an unrivalled surface finish,” says Markus Axtner, MT Aerospace’s senior vice president, additive manufacturing program management. “This is made possible not only by using a roller coating system but also by the precise positioning of every laser on the entire FormUp 350 platform.”

The combination of minimal amount of substrate, reduced post-printing work and a build rate 15% higher than other machines has resulted in improved lead time and reduced overall part costs for MT Aerospace’s customers. The AddUp systems are fully integrated in MT Aerospace’s offering, which covers the entire development and production chain.

“Having our machines installed in the industrial setting of MT Aerospace in Augsburg (Bavaria) makes our technologies accessible to European manufacturers in a lot of different industries,” says Frédéric Le Moullec, AddUp sales director. “MT Aerospace's cutting-edge expertise in the design, manufacturing and certification of high-tech components is highly complementary to that of AddUp, and enables us to develop optimized additive manufacturing solutions for our customers together.”

In addition to these machine acquisitions, MT Aerospace and AddUp are also engaged in a partnership to support industrial customers in their AM journey by combining both their expertise. AddUp’s legacy, inherited from Michelin and Fives, to make industrial AM machines and its track record of developing parts such as implants, Formula 1 engine components, satellite antennas and aircraft flight equipment works well with MT Aerospace’s experience manufacturing Ariane rocket parts.

MT Aerospace says these machines and the partnership with AddUp will play a key role in its growth plan. “As an end-to-end AM contract manufacturer for high-quality products, we rely on a high performance machine park,” says Thomas Weitlaner, senior vice president, AM Sales. “The two FormUp 350 systems are well suited to further strengthen this machine park. This gives us the possibility to grow further with our customers in various industries — from space and aerospace, to defense, automotive and energy — and offer them final, high-quality products in serial production.”

Related Content

-

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

-

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

-

3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.