HP Partners With INDO-MIM to Expand Metal Additive Manufacturing

Formnext: INDO-MIM has initially invested in three HP Metal Jet S100 printers as part of this collaboration and is in the process of becoming a certified partner of HP’s Digital Manufacturing Network (DMN) of leading manufacturers serving international markets across the globe.

The Metal Jet S100 is not a single printer but a full suite of equipment for metal part production. It includes (left to right): mobile build units, the Powder Management system, the Metal Jet 3D printer, the Curing Station and the Powder Removal system. Photo Credit: HP

HP Inc. is partnering with INDO-MIM (Indo-MIM Private Ltd.), one of the world’s largest players in the metal injection molding (MIM) industry and an emerging player in the additive manufacturing (AM) powder industry. The partners say this collaboration marks a significant step toward advancing metal AM technology and expanding its applications in various industries. INDO-MIM has initially invested in three HP Metal Jet S100 printers as part of this collaboration, strengthening their commitment to advancing additive manufacturing (AM) globally.

INDO-MIM is in the process of becoming a certified partner of HP’s Digital Manufacturing Network (DMN) of leading manufacturers serving international markets across the globe. Two of three printers will be stationed at INDO-MIM's Bangalore, India, facility. One of them will focus on new material development, while the other will be driving application development and cater to customers in the Middle East, India and the rest of the Asia-Pacific region. The third unit will be based in Texas, reinforcing INDO-MIM’s commitment to providing localized support for North American clients and expanding their production capabilities.

“We are proud to partner with INDO-MIM to create new possibilities for their customers leveraging our S100 solution and metals additive manufacturing capabilities,” says Savi Baveja, HP president of personalization and 3D printing, and chief incubation officer. “We are thrilled to work with INDO-MIM to drive new metals applications, expand material possibilities, and increase precision and productivity. We share a common purpose to accelerate innovation, grow adoption and scale breakthrough applications.”

Indo-MIM is also expressed his enthusiastic about the collaboration. “Our partnership with HP signifies a milestone in our journey to provide cutting-edge, production-ready 3D metal binder jet solutions to our customers,” says Krishna Chivukula Jr., Indo-MIM CEO. “The acquisition of HP’s Metal Jet S100 printers equips us with the latest technology, enabling us to meet the growing demands of our customers with efficiency and precision, as well as expand the library of materials qualified on the HP printer platform.”

HP and INDO-MIM are not only expanding their AM capabilities but are working together to qualify new HP Metal Jet materials like M2 tool steel and others that will unlock a broad array of capabilities, including improved properties and dimensional tolerances.

Additionally, INDO-MIM will leverage HP’s Process Development software to deliver innovative solutions for speed, scalability and adaptability. “The HP Process Development software is very impressive for managing application development workflows, while the newly released Digital Sintering software will help INDO-MIM simulate and speed up the process to reach production quality parts in fewer iterations,” says Mukund Nagaraj, head of additive manufacturing.

Both HP and INDO-MIM are committed to advancing innovative technology and sustainable manufacturing. Together, these companies are well-positioned to unleash the full potential of metal additive manufacturing, helping transform markets including aerospace, automotive, consumer electronics, health care, industrial and more.

- Read about HP expanding automation solutions for advancing 3D printing path to production. HP’s Jet Fusion automation solutions are designed to simplify workflows and reduce costs for high-volume 3D production. The company has also expanded its materials, HP Digital Production Suite and HP Digital Production Services for polymer and metal customers.

- Learn more about HP printing solutions for accelerating production applications. HP’s commercial Jet Fusion 5400 Series and Metal Jet S100 solutions accelerate additive manufacturing production applications.

Related Content

Freeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

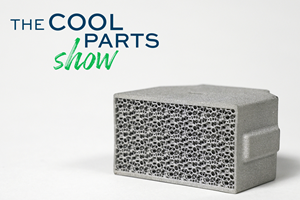

Read More3D Printed Metal Filters Protect Circuit Breakers from Explosion: The Cool Parts Show #57

New high-voltage circuit breakers from Schneider Electric make use of 3D printed metal filters to protect people and equipment in the event of an overload. Binder jetting provided both the geometric complexity and price point needed for these parts.

Read MoreVideo: Binder Jetting Production Workflow at Freeform Technologies

Additive manufacturing via binder jetting includes a sequence of downstream steps. During a visit to the Pennsylvania metal 3D printing part producer, I had the chance to walk through this process.

Read MoreAMGTA Research Demonstrates Sustainable Benefits of Binder Jet 3D Printing

Research from the Yale School of the Environment shows substantial reduction in GHG over traditional casting methods.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More