Generative Design Improves Micromobility FUV: The Cool Parts Show #19

Arcimoto’s lightweight “Fun Utility Vehicle” gets even lighter thanks to parts that could only come from additive manufacturing. On this episode of The Cool Parts Show, some of the craziest automotive parts you have seen.

Share

The Fun Utility Vehicle (FUV) from Arcimoto is a car designed with an eye to micromobility and environmental sustainability. The lightweight, low-cost electric car, which came to market last year, was designed for the kinds of typical short trips involving one or two people that match the vast majority of car trips drivers take. What the company did not see is the way its non-traditional car was still subject to the limitations of conventional manufacturing. An encounter between Arcimoto founder Mark Frohnmayer and Avi Reichental, co-founder of ParaMatters, allowed the latter to observe how a variety of the car’s components could be redesigned for lighter weight through the combination of generative design and additive manufacturing (AM).

On this episode, we look at FUV parts before and after their redesign for AM. We show replacement parts made additively that may look crazy, but perform the same function as their conventional counterparts with less weight and perhaps considerably fewer manufacturing steps. | Season 3 of The Cool Parts Show brought to you by Carpenter Additive.

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related resources

- Our original article on the FUV and the opportunity for AM

- A GM bracket redesigned using generative design

- A Ford part now made through 3D printing — The Cool Parts Show S2E1

- The link between additive manufacturing and the circular economy

Transcript

Peter Zelinski, Additive Manufacturing

Does your car fit the way you drive? Most trips are short; most of the time there's just one or two people in the car. What if our vehicles could be thinner, lighter, cheaper; what if our vehicles better fit what we use them for? There's a company in Oregon that's trying to realize that, and additive is helping to make it possible. We’re talking about lighter weight transportation that’s easier to manufacture on this episode of The Cool Parts Show.

Stephanie Hendrixson, Additive Manufacturing

Season 3 of The Cool Parts Show is brought to you by Carpenter Additive. The company's Athens Alabama Emerging Technology Center is an end-to-end additive manufacturing production facility, with everything from materials development through post processing under one roof, ready to help you with your next metal 3D printing job. Check them out at carpenteradditive.com. Now, back to the show.

Peter Zelinski

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Peter Zelinski

Welcome to The Cool Parts Show, our show all about cool 3D-printed parts made by viewers like you.

Stephanie Hendrixson

One quick note before we begin, we don't know when you're going to be watching this episode, but we are filming it right now under social distancing guidelines. Pete and I are both here in the studio sitting at different ends of the same table and you're going to see us cut side by side when you actually watch this. So we'll go ahead and jump in. Pete, you brought this part today and set it in front of me, what is this?

Peter Zelinski

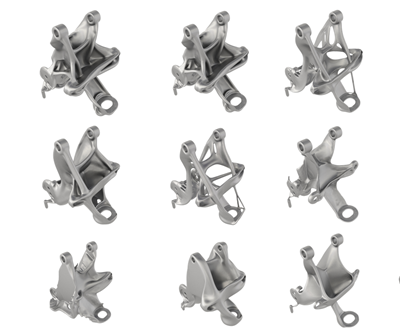

That part is the steering knuckle and the hub carrier for the Fun Utility Vehicle, FUV, from Arcimoto. It is a vehicle that is tailored toward the ways we actually use cars. You know, mostly we go on short trips, and mostly there's just one or two people in the car. There are two of those parts: a left- and a right-hand version, and it's all about getting a lighter weight for this vehicle that is already very lightweight in its current form. That part was produced through generative design, mathematical computation aimed at realizing the form that uses the minimum mass, minimum material possible. Let me just show you.

Peter Zelinski

So that's a steel part, MS1 steel. It was made through additive manufacturing on an EOS machine, direct metal laser sintering. As you can see, generative design produces shapes that really only 3D printing could produce.

Stephanie Hendrixson

Okay, so all of that sounds really cool. Generative design, I want to ask you about all of that. But this car doesn't look like anything I've ever seen before. Tell me more about it.

Peter Zelinski

Right. So this car is about micro-mobility. It's about sustainability. It's about tailoring the car, scaling it down so the vehicle is only the size and only the cost that it really needs to be. The car is really the vision of Arcimoto's founder and president Mark Frohnmayer. He has a lot more to say about the FUV. Here he is.

Mark Frohnmayer, Arcimoto

Cars are amazing. They carry five to seven people hundreds of miles at a time. But there's a giant disconnect between what a car can do and how we actually use them on a daily basis. Cars carry five to seven people, take up a ton of space – we use them by ourselves or with just one other person, relatively small amount of stuff to get around town. And that disconnect creates a massive amount of inefficiency. Both in terms of the amount of space that we take up, and I mean, you think about this as you're rolling down a residential street, that street is really designed so that one person can pass one other person. It's crazy, totally, totally crazy. Really the root of the idea is that we're not trying to change people's behavior patterns really, at all. We're just trying to build a much better tool for the job that they're already doing, and in doing so, make a clean vehicle that is an order of magnitude more efficient than cars on the road today, that takes up much less space, that you can maneuver very easily through traffic and then ultimately, is a lot less expensive so the much wider market can participate in clean mobility. We right now dedicate about half of our urban landscape to asphalt to move and park cars. Ultimately, we see the opportunity to actually reduce the amount of our civic landscape that is dedicated to cars for more productive uses. But I would say the biggest initial benefit for commuters is you're going to show up to work with a smile.

Stephanie Hendrixson

Alright, so that's all really cool, but I can't help but notice in all of the b-roll you've shown me so far I don't see anything that looks crazy and pink like this.

Peter Zelinski

Yeah. So the FUV is already on the market. It is in full production, and the parts are all made conventionally right now. Made through machining, welding, processes we're familiar with – but the company wants to get the car lighter. The car is already very light: it is 1,300 pounds. You know, by comparison, can I reveal what car you drive? Your Honda Civic is 3,000 pounds by comparison. So the car is already very light but their goal is to get it to 1,100 pounds. They didn't quite know how to do that, they began to see a way because of a chance meeting between Mark Frohnmayer and Avi Reichental. We'll talk a little bit more about that meeting. But Avi Reichental is the founder and owner of various companies that touch on additive manufacturing: XponentialWorks is one of them. But maybe more significant to this discussion is ParaMatters, which is a cloud-based, cloud-computing-based utility for generative design using software like CogniCAD to allow for realizing shapes like that.

Avi Reichental, XponentialWorks and ParaMatters

The way that CogniCAD works is we have some topology optimization algorithms that are looking for the most definitive geometry that will deliver the load-bearing conditions that we set up within the envelope. So these algorithms begin to work with very, very intense computations that can go up to millions of finite elements and quickly run all the different iterations until we get to the most definitive design. And that's the only design that you get back from CogniCAD as the answer.

Stephanie Hendrixson

Okay, so what Avi is saying is really interesting, like we know that additive manufacturing can make these crazy cool organic parts. But the interesting thing that he's saying is that you really kind of need software. Like It would take a human so long to come up with this design, like you really need to automate parts of the design process.

Peter Zelinski

So generative design kind of reconceives what design even is – what work the human being is doing in design. So it's not a designer working in CAD software, moving shapes around to build the geometry. It is, instead, the designer takes a step back and just sort of defines the shape of the problem. What loads does the part have to carry? Where does it have to connect to the rest of the assembly? What do sort of the design space and design envelope look like? Then they let finite element analysis work out all of the math to get to the optimal solution within those boundary conditions.

Stephanie Hendrixson

Okay, so where is Arcimoto in implementing designs and parts like this?

Peter Zelinski

They're just getting started actually. The car is in production. Additive parts aren't part of it, yet. They're looking at these for weight saving. So actually the way the car was originally conceived, additive didn't look like an effective production solution, but Arcimoto didn't see all of the benefits. Avi talks about that.

Avi Reichental

He showed up with this funky looking, you know, FUV, which he calls a fun utility vehicle. I got in, the Arcimoto FUV accelerated pretty quickly, and it was an amazing test drive. And I came back and I kind of said to him, “Listen, it's really fun but it could use a diet.” And he said to me, “Well, I've been thinking myself about how we can reduce the weight because it can take us into the next category and it could improve performance and handling.” And we shook on it that night. The target that we set for ourselves together with Arcimoto is about 200 pounds. I think that we are a quarter of the way there, just with the parts that we selected. My sense is that it is a beautiful, clear canvas to continue, especially with Arcimoto because the design lends itself so beautifully for additional generative and additive technologies. And as you walk through the factory, which I know you have done, you can see so many opportunities to simplify the fabrication to combine part count and simplify the supply chain.

Stephanie Hendrixson

Okay, so Avi just brought up something that we haven't touched on yet, this idea of simplifying production and by consolidating assemblies. Is that the case with this part?

Peter Zelinski

Yeah, that's totally the case with that part. So this is streamlining in multiple ways. It is saving weight and also simplifying manufacturing. We can do this side by side: I've got the original version of that part. Here is the steering knuckle hub carrier as it exists now. So, this is a weldment. It consists of all these machine components that are joined together through welding in a separate assembly step, a step that goes away with the version of the part that you have. What used to be an assembly, what is an assembly right now made through welding in the current manufacturing process would become just a one-piece part printed complete one time in that version. I want to show you something else. I left another part beside you, another generative design part.

Stephanie Hendrixson

Okay, so this one is bigger, but it's also lighter.

Peter Zelinski

This is a control arm. There's a right- and left-hand version. The part you're holding is aluminum and it replaces or could replace this eight-piece weldment.

Stephanie Hendrixson

Okay, so is this another case of 3D printing replacing that conventional part?

Peter Zelinski

Sort of, but not really. That is a casting. 3D printing was still essential to realizing that form, but in a different way. That part, that aluminum part, was made through investment casting. So a 3D-printed tool was created, a 3D-printed pattern made in polymer, and that pattern was self-sacrificial. Sand was packed around it to make the mold and then that pattern melted away as the molten Aluminum was poured in. The reason they did it that way is simply because the part is too big for the particular EOS machine that they were using to do this 3D-printing work, so they used a bigger polymer printer. They printed the pattern and made the form through investment casting. Investment casting is kind of a more accessible way to use 3D printing to realize the benefits of generative design that's maybe more accessible than directly metal 3D printing a really large part like that.

Stephanie Hendrixson

Okay, so what we have here are sort of two paths to a similar result, generative design to 3D print a part directly, or generative design to 3D print a pattern that can then be used to cast the part.

Peter Zelinski

That's right. Yeah, two paths forward. Like I said, Arcimoto is just getting started in imagining the role that additive manufacturing and 3D printing is going to have in its manufacturing process. But the role might look like this: smaller parts directly 3D printed, larger parts made through investment casting using a 3D-printed tool. Here's another example of a smaller part, a recent one they did. Here's the gas pedal. So it just shows in a future version of the FUV, the driver, the user will be directly touching, directly engaging with metal 3D-printed parts. Here's a little more from Mark Frohnmayer about their manufacturing and how they're thinking about that.

Mark Frohnmayer

The path we chose was really all about vertically integrating metal productions, metal part production, and then the final assembly line all under one roof. And that gives us a lot of flexibility in terms of both beginning that scaling production process, and then building multiple variants on the same platform and iterating quickly in the R&D phase. So we do laser cutting, CNC forming, and then robotic welding. It's sort of like sheet metal origami and Tinkertoys for vehicles. And those tools, that palette gives us a lot of room to play for doing different variations on the product. I think what you see in this, this partnership with XponentialWorks, is us, with them looking a step down the road and saying, “We want to be there when that manufacturing technology is ready for scale, so that we can apply really the same sort of the same, you know, supercharged flexibility that we have now with the next generation of industry 4.0 Technologies.”

Stephanie Hendrixson

Okay, so there's something else that I think is really exciting about this. So this combination of generative design and additive manufacturing, it lets you make these lighter-weight parts. They use less material. It simplifies the manufacturing process and you end up with this car that's more energy-efficient at the end of it. So it's all of these things working together. It's the material, the design, the manufacturing to arrive at a product that is more sustainable itself, but it's also enabling this whole vision of more sustainable transportation like right-sizing the car and the way that we think about driving to form a more sustainable future.

Peter Zelinski

So yeah, so right-sizing the car could lead to right-sizing roads, which could lead to different designs of communities and neighborhoods. Yeah, that's why we're doing this show, right? It's not just the cool parts. Additive manufacturing makes the parts possible, but the parts are cool because they make a transformation possible. And this might very well be the biggest potential transformation we've had a chance to talk about.

Stephanie Hendrixson

Okay, so I think I got this. These are two parts for the fun utility vehicle from Arcimoto, the FUV. This is a 3D-printed steering knuckle reimagined with generative design. It combines a couple of different parts that would previously be welded together. And then this control arm is a similar story, it uses generative design to come up with this geometry, but then it was 3D printed in plastic and they use the plastic to make a mold for a casting. So, using this combination of additive and generative design, ParaMatters and Arcimoto are trying to reduce the weight of this car from 1,300 pounds down to about 1,100 pounds. I think that's it for this episode of The Cool Parts Show.

Peter Zelinski

Thanks for watching. If you want to tell us about a cool part you're working on maybe even a major transformation you're going to bring about, email us at coolparts@additivemanufacturing.media.

Stephanie Hendrixson

If you like the show, we hope you'll subscribe, tell a friend, and you can find all of our existing seasons and episodes on YouTube or at TheCoolPartsShow.com

Peter Zelinski

For a lot more about 3D printing, about additive manufacturing, about the technology, about where it's succeeding, read more, find more at additivemanufacturing.media.

Stephanie Hendrixson

Thanks for watching.

Stephanie Hendrixson

Thank you to our sponsor Carpenter Additive. Listen to additive manufacturing podcasts, attend webinars and learn more at CarpenterAdditive.com.

Related Content

Additive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read More7 Things We Saw at Formnext 2024 — Video Playlist

There were countless processes, applications and announcements at Formnext 2024. Here are seven standouts Peter Zelinski and Stephanie Hendrixson caught on film.

Read MoreTwo 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

Read MoreRead Next

Why GM’s Electric Future Is Also an Additive Future

Production capacity isn’t the only reason that additive has been slow to make inroads into the automotive industry. There is a larger barrier to entry—one that General Motors and Autodesk are working to overcome.

Read MoreGenerative Design to Bring Weight and Cost Savings for Micromobility FUV

The “Fun Utility Vehicle” from Arcimoto is already in production, and already lightweight. But after just 30 days of redesign for additive manufacturing, the company discovered major components could be made lighter still, and production could be made simpler.

Read More3D Printing for Production at Ford: The Cool Parts Show #7

The parking brake bracket on the Mustang Shelby GT500 is now 3D printed instead of stamped. Learn how Ford is thinking about additive manufacturing in this episode of The Cool Parts Show.

Read More