3D Printed Heat Exchanger Uses Gyroids for Better Cooling | The Cool Parts Show #43

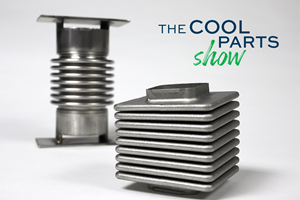

Replacement heat exchanger for a helicopter is half the size and delivers 4× the cooling, thanks to a geometry that could only be made via additive manufacturing.

Share

A 3D printed helicopter part? Advanced Engineering Solutions applied geometry that could only be made through additive manufacturing to the redesign of a heat exchanger for the gearbox oil of a helicopter. The result: four times the cooling in a heat exchanger one half the size of the original. Gyroid lattices inside this heat exchanger maximize inner surface area to achieve the more effective heat transfer. This part was one of the audience-selected winners of our first-ever contest, The Cool Parts Showcase. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- Advanced Engineering Solutions

- Winners of the Cool Parts Showcase

- Another gyroid cool part: Quantum physics vacuum chamber

- Introduction to laser powder bed fusion

- EOS

- Additive Works Amphyon for Creo

Transcript

Stephanie Hendrixson

This helicopter heat exchanger is half the size and four times more efficient than the one it's designed to replace.

Peter Zelinski

An audience selected winner of our Cool Parts Showcase on this episode of The Cool Parts Show.

Peter Zelinski

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Peter Zelinski

Welcome to The Cool Parts Show.

Stephanie Hendrixson

This is our show all about cool, unique, interesting, amazing and now award winning 3D printed parts. So in 2021, we ran our first ever contest, The Cool Part Showcase. We got dozens of entries. Pete and I got to choose the finalists, but you, the viewers, got to vote and choose the winners, and we have one of those parts here in the studio with us today.

Peter Zelinski

The Cool Parts Showcase. This was so much fun. We had finalist parts on display at the Additive Manufacturing Conference and Expo. We had winners in each of three different categories based on 2,500 votes we got from the audience. So this part right here is the winner in the category, Best Proof of Concept.

Stephanie Hendrixson

Yes. So this part is a heat exchanger for a helicopter. It was designed and submitted to us by Advanced Engineering Solutions.

Peter Zelinski

Right. Heat exchanger for a helicopter. This is a proposed replacement for a heat exchanger on a military helicopter been in service for decades. This particular heat exchanger cools gearbox oil, and it uses the helicopter's own fuel as the cooling fluid. The conventional heat exchanger uses shell and tube design, which is typical of heat exchangers, meaning tubing is bent around in an array parallel to itself, and the cooling fluid washes over that. What is special about this metal 3D printed version is on the inside. The complex geometry on the inside provides for much more effective heat transfer than that conventional design.

Stephanie Hendrixson

Right. And there's a couple of other things going on here too. So that conventional tube and shell construction that you described, very labor intensive, lots of different parts coming together. And it might mean that you're carrying more material, you're carrying more weight than you might want to. And as we know, with aerospace lightweighting is almost always part of the goal. And so the ability to 3D print something like this in just one piece dramatically reduces the assembly, simplifies the manufacturing, and also can help remove weight and material out of the heat exchanger.

Peter Zelinski

Labor savings weight savings. There was space savings, too. So this heat exchanger design is one half the volume of the existing heat exchanger, and it's four times more effective at cooling.

Stephanie Hendrixson

But key to a lot of the things that we're talking about is what's going on in the inside. Some features that are not easily seen at least from this angle of the gearbox. But on the inside, instead of all those tubes bent together, this thing is actually packed full of gyroids.

Peter Zelinski

Gyroids. So these mathematically complex surfaces that in the case of this heat exchanger, provide for an optimal relationship between the metal surface area and the two fluids, enabling more effective heat transfer. To talk more about this. Let's bring in the designer of this heat exchanger. This is Dr. Andreas Vlahinos, and he is chief technical officer with Advanced Engineering Solutions.

Dr. Andreas Vlahinos

Nature is using these geometries for a long time. Soap bubbles are very good examples. If you have two rings and you dip the in soap water and bring them out, it generates a nice, beautiful surface, which is not cylindrical. It finds the minimum possible surface area, which connects those two rings. We call that minimal surfaces because they minimize the surface, because the soap bubbles stretches itself and automatically nature finds the optimal designs. These designs, if they're periodic, we call them triply periodic minimal surfaces because they repeat themselves in all three directions. So triply periodic minimal surfaces. And some of them are gyroids or diamonds. These surfaces exist in nature. Butterflies use them in their wings so they can have a high span to thicknesses ratio. And a lot of other biomimicry type of applications can come out of. The problem was these surfaces were not discovered till the late seventies, and then when they were discovered we just had the equations. I was so excited about them, but you couldn't do anything. We couldn't manufacture them and we couldn't build them in the CAD systems. Now, with additive manufacturing, we can build these surfaces because they don't need machining.

Stephanie Hendrixson

So Andreas just spoke about how 3D printing enables us to build these interesting geometries like gyroids that would not have been possible previously. But in this case, the gyroids actually help with 3D printing because they are self-supporting.

Peter Zelinski

How's it 3D printed?

Stephanie Hendrixson

This was made with laser powder bed fusion. Specifically, EOS printed this on one of their M290 machines. It went through just minimal post-processing, really just threading these holes and a little bit of surface finishing, and it was printed without supports. So almost exactly how you see it here.

Peter Zelinski

So laser powder bed fusion, what's the material?

Stephanie Hendrixson

This is aluminum silicon ten magnesium. So it's an aluminum alloy.

Peter Zelinski

And there's no support structures.

Stephanie Hendrixson

So not in the way that we typically think of them. So the gyroids themselves are self-supporting, but you can't just build gyroids like free floating in the powder bed. So if you take a look through the bottom of this heat exchanger, you'll see a lattice on the inside and that lattice is really just there to provide a surface that you can build the gyroids on top of. But it's not a support structure that would be removed afterwards. It's something that has become a feature of this part. It's built in, it's not coming out. So it's a support structure, but not in the way we maybe usually talk about them.

Peter Zelinski

OK, there's that lattice on the inside, there's a lattice on the outside, like it looks like a Faberge egg. Like, what's that?

Stephanie Hendrixson

Yeah. So also kind of a support structure. So these kind of crisscrossing ribs are here to allow for the wall thickness to be thinner. So because you have this support on the outside, you can build a thinner wall without losing the strength. And this allows again for material savings and reduced weight.

Dr. Andreas Vlahinos

The mission in especially aerospace things when they fly is to minimize weight. Of course, you don't want to compromise safety. So instead of making it very thick, we put the ribs outside which they enhance the performance. And the ribs, where ever there is a dip, they are thicker. They're not uniform in height, number one. So for the outside, there is a lattice structure, two and a half deep lattice structure wrapped around outside. Inside also there are lattice structures, which they act as a screen. So you try to double dip, those screens act also as supports for the gyroids. These gyroids have three amazing properties. First of all, if we fill a volume with the gyroids it splits the volume in two different domains, two different volumes. They don't touch each other and they are continuous, which is ideal for a heat exchanger. You can pump fluid in one and pump the other fluid in the other and they intermingle very well. The second amazing property, they don't have a weak axis. They can't bend like that. They continuously turn. So they're very, very strong in compression, for example. So this thing, it goes about ten times the required performance for pressure. In the third feature, they keep turning themselves up so they don't need supports. So when you print them, you don't need to have any support inside, because how would you be able to send somebody inside here to remove the supports? That would be very difficult. So the entire thing was printed with no supports. And of course no build failures because we did simulation.

Peter Zelinski

Andreas talked about simulation, and that's a really important part of this project. A lot of the engineering was done digitally in the form of simulation, so the fluid flow and the heat transfer were simulated to get the design right and then the additive manufacturing build was simulated first before it was ever produced physically.

Stephanie Hendrixson

Right. So the software was a huge piece of this, not just in figuring out the design, but in proving that the design was going to work, proving that it was going to print correctly before they actually went to the printer. So, Pete, refresh my memory. Like what were some of the software tools that they used?

Peter Zelinski

Fluid flow was simulated. Computational fluid dynamics was used to look for things like recirculation regions, places where the fluid got stuck in a loop, meaning it wasn't performing in a power efficient way. So the software used for that simulation came from PTC and from Ansys. And then the laser powder bed fusion build was simulated also before it was 3D printed and the software used there was from Additive Works.

Stephanie Hendrixson

So the physical object that we have here is actually the result of a whole lot of virtual digital work before they ever got to the point of 3D printing. So this heat exchanger, it works. It works as it was designed. It's more efficient than the conventional alternative, and it was printed without build failure.

Peter Zelinski

Right. And I want to draw a circle around that. Just how important and how powerful the simulation tools proved to be. We talk a lot about how additive manufacturing is an aid to invention. It's easy to iterate with additive manufacturing. Keep making part after part, after part, after part until you get exactly the design you want. But digital simulation can be an even faster way to develop a design. Iterate virtually. And that proved to be very important here. The fluid flow properties were were nailed down in advance and the recirculation regions that I mentioned, some of those were found and it led to modifications in the design before it was ever made physically. Additive manufacturing as well. We've talked about also how in additive, metal additive in particular, there's trial and error involved. That's part of process development, except software tools are bringing more and more sophistication to the table here as well. In the case of this particular part, there wasn't trial and error in terms of physical build. The build was simulated first, and it allowed the first part printed to be a good part.

Stephanie Hendrixson

So this is digital simulation and digital manufacturing in the form of 3D printing working together.

Dr. Andreas Vlahinos

So you can change something and you see immediately the impact of your change on the design performance. So you can do really cool stuff. It's like having a spell checker for the design in real time. If you have that freedom, you're not afraid to strike crazy ideas.

Stephanie Hendrixson

All right. Are we ready to wrap this up?

Peter Zelinski

I think so. You start.

Stephanie Hendrixson

All right. So this is a heat exchanger for a helicopter. This exchanger cools the oil, the gearbox oil for the helicopter with the fuel of the aircraft. So conventionally, a heat exchanger like this would be made with like a tube and shell construction, where you've got a lot of different tubes running through it that have to be bent and assembled together. Here this was 3D printed in just one piece. So this exchanger was designed by Advanced Engineering Solutions, and in this case, the tubes are replaced by internal gyroids and lattices, which allow for this heat exchanger to be smaller, to be more compact, to be lighter weight, and also to function more efficiently at cooling that oil.

Peter Zelinski

Yeah, more efficient design. And that efficiency comes from an internal geometry that could only be produced through 3D printing. Simulation tools were used to arrive at that geometry and to simulate the build in advance. This was made from an aluminum alloy on a laser powder bed fusion machine from EOS M290. Minimal post-processing. Some machining at either end for the connection to the rest of the assembly, but otherwise this is one solid 3D printed piece replacing what used to be an assembly and ready for long service life on a military helicopter.

Stephanie Hendrixson

All right, I think that'll do it. Thank you again to Advanced Engineering Solutions for submitting this part. Congratulations on your win. We're going to be doing episodes with the other winners as well, so keep an eye out for those.

Peter Zelinski

Yeah, more episodes coming up with Cool Parts Showcase winners. Subscribe so you don't miss those. Catch our back episodes. If you're seeing the show for the first time, they're all at TheCoolPartsShow.com.

Stephanie Hendrixson

One important note, you do not need to win a contest to be featured on The Cool Parts Show. So if you do have a cool part you'd like us to consider for a future episode, you can email us, CoolParts@AdditiveManufacturing.media. Thanks for watching!

Peter Zelinski

This episode is brought to you by Carpenter Additive. We're past the point of not knowing how to qualify metal 3D printed parts. We know it's just that different end users of those parts have different qualification requirements. Additive manufacturing service providers have to navigate that, and Carpenter Additive has to think about that in tailoring powder management solutions.

William Herbert

Our customers typically will have, if they are a service provider, they will have a series of end user customers, who may be say OEMs in the aerospace world, and each of them has as a fairly large team of engineers who have been doing this for decades or more and have developed all these standards, regulations, paperwork. So it is certainly a challenge to thread the needle between all of these different requirements. We start really high level. We walk on the shop floor. We ask them about their source to sink, how do you bring in the materials, goods in, send that material to each of the systems. And then what we're really interested is how do they reuse that material? So what we do is called a value stream map. Pretty often that leads to a series of things that were either overlooked or hadn't really boiled up to the surface yet, in terms of potential risks or potential challenges or inefficiencies that exist. A lot of the customers we work with, especially in the more regulated industries such as space or medical or aerospace, have already been through those early learning stages. They've put five plus years into this. They've done the product design and the design for additive manufacturing. And now they're starting to reach some of the more finicky problems that you get when you're at the scale of maybe 5 or 10 machines, they're running different materials simultaneously doing different programs. We get to take the best from the medical field and the aerospace field. We understand the specifications and the standards that exist in each of those fields, and we can sort of take the best elements of those and customize that to our customers.

Related Content

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreFlexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreRead Next

New Opportunities for Quantum Physics: The Cool Parts Show #11

What does 3D printing have to do with quantum physics? We'll look at how the technology is enabling quantum physics research in this episode of The Cool Parts Show.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More