3D Printed Headgear that Can Take a Hit: The Cool Parts Show #31

A custom helmet made via Multi Jet Fusion has allowed Sarah Piersanti to get back to practicing jiu-jitsu without fear of damaging her cochlear implant.

Share

When Sarah Piersanti received her cochlear implant, the experience was bittersweet. After losing her hearing unexpectedly, the device was a godsend — she could hear her husband and children again, and be more independent in her daily life. But it also took away something core to who she is: martial arts. The delicate nature of the processor now embedded in her skull meant that Sarah could no longer practice jiu-jitsu alongside her family and friends for fear that one wrong move that might damage the electronics.

A chance connection changed all that. After learning about a local clinician with connections to 3D printing, Piersanti had a solution. Learn how Eastpoint Prosthetics and Additive America collaborated to design and print a custom helmet that could protect the processor in the video below. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- Additive America’s mission to develop and advance a digital workflow for orthoses and prostheses

- Additive America and EastPoint Prosthetics on LinkedIn

- AM 101: Multi Jet Fusion

- How 3D printing is transforming another bespoke device industry: dentistry

Transcript

Stephanie Hendrixson

This 3D printed helmet is as tough as the woman it was made for. We're talking about headgear that can take a hit in this episode of The Cool Parts Show.

Pete Zelinski

The Cool Parts Show is brought to you by Carpenter Additive. The company's Athens, Alabama, Emerging Technology Center is an end-to-end additive manufacturing production facility with everything from material development to post processing under one roof, ready to help you with your next metal 3D printing job. Check them out at CarpenterAdditive.com. Now back to the show.

Pete Zelinski

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Pete Zelinski

Welcome to The Cool Parts Show.

Stephanie Hendrixson

This is our show all about cool, unique, interesting, life changing, 3D printed parts.

Pete Zelinski

Life changing, okay, new adjective. And we're looking at what looks like a helmet here. Is there a life changing story with this cool part?

Stephanie Hendrixson

There is indeed so this helmet was designed to be worn during jiu-jitsu training, and it has had a major impact on the quality of life for the person who wears it.

Pete Zelinski

Okay, I’m in. You had me at jiu-jitsu. So who's this helmet for?

Stephanie Hendrixson

So what we have here is a copy, but this design was created for a woman named Sarah Piersanti in North Carolina. And to understand what is so special about this helmet, you have to really understand what is so special about Sarah. So for her and her family martial arts jiu-jitsu, it's not just a hobby, it's really kind of a way of life.

Pete Zelinski

Okay. All right. I want to hear how we get from there to 3D printing. So can we meet her?

Stephanie Hendrixson

Sure.

Sarah Piersanti

Martial arts has played a pretty big role in my family for the last six years. It started with my daughter and I by ourselves, and I met my husband at martial arts, specifically jiu-jitsu. His kids also do martial arts. And together as a family, we help to run a jiu-jitsu academy here in Knightdale. So I've always been an active person, whether that's hiking or skiing and snowboarding in the winter, or going to the beach and going for runs and swimming, and cycling, I've done triathlons. I rode my bicycle across the country when I was in my early 20s. And then martial arts was just a natural progression from there.

Stephanie Hendrixson

Okay, so that kind of gives you a sense of who Sarah is, the ideal lifestyle that she likes to lead. But a couple of years ago, Sarah had this setback, you might have noticed in that video, she has a cochlear implant. So a couple years ago, she kind of mysteriously lost her hearing, it could have been a virus, it might have been a training injury, doctors don't really know. But now she has this device that helps her hear. So a couple of different components to it. There's like the earpiece that goes over her ear that has microphones to capture sound. There's the transmitter on the back of her head, she has like a flower on it. And then that sits right over top of this internal processor. So the processor is actually under her skin, but on top of her skull. And then there are these electrodes that lead down to her auditory nerve so she can hear. But the issue really comes from that processor. The earpiece and the transmitter, she can take those off, but the processor is always there and it's pretty delicate. And so although she got her hearing back, she wasn't able to do jiu-jitsu anymore. She wasn't able to do like some really simple things like roughhousing with her kids.

Sarah Piersanti

While I could function in the real world a lot better because I could understand what people were saying, and I could hear my kids better and I could, you know, I had better independence. It took away all the things that made my life really fulfilling like being able to run around with the kids, participating in martial arts. Without this headgear, I became a little bit more withdrawn from my friends and stuff like that, because all of my friends are also in the martial arts community. Getting the cochlear implant was really bittersweet. It allowed me to do a lot of the things that I really needed to do in life, but it prevented me from doing all the things that I wanted to do in life.

Pete Zelinski

Okay, so I think I see how this is gonna prove to be life changing. So cochlear implant, so I know a little something about that. So sensitive electronics that detect and interpret vibration in the way that a deaf person's hearing no longer can. And yeah, I can see why she would lose jiu-jitsu as a result of that. She's got this delicate device that's with her every moment all the time. And so she can't take blows anymore and she even has to be guarded about getting physical with her kids. I can see how that would have pained her. So was it hard to get to a solution?

Stephanie Hendrixson

So it was harder than you might expect? Like jiu-jitsu is a pretty minimal sport as far as equipment goes, you wouldn't normally be wearing headgear, or a helmet of any kind. So Sarah did try some off the shelf options, headgear meant for other sports. But the issue is with most helmets, they're not designed to accommodate something like a processor like that. And so if she were to get hit in the head while wearing like a bike helmet or something, that processor is going to end up bearing the brunt of the blow. So she and her husband tried a couple of do it yourself solutions, like they cut up exercise mats and tried to make something themselves, but never quite came up with anything that was durable enough and strong enough and comfortable enough for her to wear for martial arts.

Pete Zelinski

I listened to that. And I think for you and me, I mean, because we do this show, it's obvious to us 3D printing is a solution here. We've done episodes on mass customization, multiple episodes on products tailored to the individual through 3D printing. But there are industrial manufacturers who have problems that 3D printing can solve, and they have a hard time getting there. So Sarah is a martial artist and a mom. Of course, she's going to try the kinds of solutions that you described. That's what's there for her to find and think of. I guess I'm ready. How did she find her way to 3D printing or how did 3D printing find her?

Stephanie Hendrixson

Yeah, so kind of through chance, she had a friend who told her about this place called Eastpoint Prosthetics. They make different orthotics, prosthetics, braces, all those kinds of things. And her friend told her about this clinician there Brent Wright, who had some connections to 3D printing. She decided to reach out to Brent, she went in for an appointment, and here's what happened.

Brent Wright

It was funny because typically, we do helmets and such for babies that have some sort of flat spot on their head or some sort of abnormality of shape of their head. And I realized I had gotten an email from somebody that was an adult that said they needed a helmet, and I just thought that was just the oddest thing. I was like, well, maybe they'll bring their child and that's what they need. So when Sarah came to my office, and it was only her, I'm like, Oh, this is interesting. And then she told me her story about how she had lost her hearing, how she had gone through the process of the cochlear implant, how she had kids and was not able to play even simple things, roughhouse with them play catch, because of the potential impact that it would have on her processor. Many of these devices are over $200,000, pushing $300,000, not including surgery. And so you can imagine how important it is to protect these devices. The neat thing is, is that Eastpoint had all the technology because we do helmets and some of the tribal knowledge that goes along with fitting a helmet.

Sarah Piersanti

So I went to Brent's office for our initial visit, and I was expecting to, you know, go in and just to talk, but he actually pulled out this iPad with some really cool technology attached to it and asked me very nicely to put this sock over my head, and he had like an eye hole cut out. I sat in a chair nice and still, and he kind of scanned my head with this iPad and special program. And the next thing I knew there was a 3D image of my head that he could spin around.

Pete Zelinski

Okay, so I have a lot of questions. She's there in the office, he gets out the iPad, they put the sock over her head. She gets scanned. Is it easy or hard to get from scan data to 3D printed helmet? Was there iteration involved?

Stephanie Hendrixson

So that's a good question. If you were making something like this the old fashioned way, it would be a really manual process, like you probably would go through a couple of iterations, you would be doing a lot of tweaking to the design. But with the digital workflow, where you're scanning, and then 3D printing, a lot of the iteration and design work actually kind of gets front loaded into that process.

Brent Wright

The thing with prosthetics and orthotics is it's not just a scan, like you would do something for automotive, like it's definitely going to fit, it's dimensioned. You're actually working with something that is living, something with tissue that has different tissue densities, somebody that has bones. And that's where the scans, you need to manipulate them in in an appropriate way. And one of the things that we do like what we did with Sarah is we knew that we didn't want to push on her processor. So I just took a stockinette and then I was able to mark that stockinette with a sharpie around where her processor was. So then when I captured it in a scan, I was able to see those marks without issue. And I knew where I needed to push and where I couldn't push. So a really neat and super precise technology that we can use and then interpret when we go to modify it digitally.

Pete Zelinski

Okay, we're pretty far into this now and I still don't know how this was made. What was the 3D printing process?

Stephanie Hendrixson

Yeah, so this was 3D printed from PA12 nylon using Multi Jet Fusion , the 3D printing polymer process from HP. And as it turns out, Brent Wright is not just an orthotists and prosthetists at Eastpoint, he's also the co-founder of this other company, Additive America, which specializes in contract manufacturing using MJF. So after Brent took the scan of Sarah's head, he worked with his Additive America cofounders, Zac Holcomb to tweak the design and get the helmet 3D printed.

When Brent Wright called me and told me about the opportunity to work with Sarah to provide a headgear for her I really thought it was a great opportunity. I was a wrestler in high school, so I was immediately interested in the idea. Brent got with her and got the scan and pulled a cap over her and got a scan of her head. And then was basically able to build the geometry off that. And then Brent and I work together figuring out where do we want thickness, where do we want rigidity, where do we want some flexibility all in the same part. So what you're seeing there with the holes in the part are largely there for rigidity, because those holes actually make the part a little bit stronger than just being solid.

Pete Zelinski

Okay, so she gets scanned, and we've got a maker of prosthetics who's got some experience with helmets, and he knows how to take that scan data and manipulate it and produce this helmet so that it's rigid in the right places, and flexible and pliant in other places. Are we getting to the solution now? Are we getting to the helmet that worked for Sarah?

Stephanie Hendrixson

Yeah, so Sarah went in for that initial scan on a Monday, and by the end of the week, they had a helmet printed for her. So Brent did some fitting, they added a little bit of padding, they put on the strap. But yeah, it worked.

Sarah Piersanti

The biggest difference between this and something on the shelf is as you can see, it has this kind of cut out section for my internal processor. My kids don't have to worry about hitting me in the head with a ball or they can jump on top of me and if I fall or they knee me in the head or something like that, when we're wrestling around, it doesn't hurt at all. I've taken some pretty good shots to the head from knees, elbows, other people's heads. Another benefit that this has is the material is really, really strong. It's flexible enough where if I need to pull it out, so I can get it on my head. It's a little bit flexible, but it's actually very, very impact resistant, it's really, really strong. I don't really feel any impact at all to my ear or that part of my head. It's very, very light. Even though it's very strong, it's also very light.

Stephanie Hendrixson

So the helmet that she's holding in that clip there is the very first original one that they printed, and she's still using it two years later.

Pete Zelinski

Yeah, that helmet and she's worn at all this time. Life changing, like you say. What has this meant for her?

Sarah Piersanti

Having this allows me not only to participate in physical activities, but it gives back the sense of norm for my family. It gave me back more of a social life. It made me a happier person. And jiu-jitsu is actually something that my husband and I really bonded over and it's something that is still a really big part in our family. And so this helmet, this headgear, gave me the freedom to get back to those things that really gave me quality of life, that really mean a lot to me.

Pete Zelinski

Can I just say, I'm really glad you introduced us to Sarah. Like "A" she's really cool, but also her story is so uplifting. This cochlear implant while restoring her hearing, potentially took so much from her, except it didn't. She kept at it, kept looking for a solution and she found her way and she got her life back. There's so much hope in that. I guess a lot of questions. I guess maybe I can bring the list down to three. Okay, can I give you three questions one by one. Okay, so first question, let's kind of go broad with this. So this story sort of shows us the potential of 3D printing for customization for meeting individual needs, but its total, total accident that she got to this, total luck. So Eastpoint Prosthetics wasn't making cochlear implant protection as a standard product, and the doctor who gave her the implant wasn't able to say, oh, now go get a helmet 3D printed so you can do jiu-jitsu. She had to look around and she just happened to find the 3D printing solution that could help her. And what all this shows really is just how early we are in the promise of what 3D printing can realize for customized prosthetics. Now Brent with his business, he's moving in that direction but all this is still so new. And I guess can we talk about that? What does all this mean? Where's this headed? What is the promise of Multi Jet Fusion for customized medical needs?

Stephanie Hendrixson

Yeah, so you're right. Brent is a super early adopter here. Most companies like Eastpoint are not using 3D printing to build orthotics and prosthetics and things like this. A lot of them aren't even using scanning, like it's still a very manual analog field overall. But Brent thought he saw a promise in Multi Jet Fusion. He actually reached out to Zac, just to find out if it would be an option for these kinds of devices. And the two of them believed in it so much that Zac uprooted his whole family from Ohio, moved to North Carolina, and they started this company, because they believe that they could develop a digital workflow for these devices based on 3D scanning, based on 3D printing, that could dramatically reduce these timelines. Reduce the cost of getting these devices.

Brent Wright

We started Additive America to really standardize the way 3D printed prostheses were made. There really is no one else that is using this technology and creating definitive prostheses with the amount of testing and such that we've put behind it. The biggest thing that we wanted to show is that one, it could be done and two, it is truly life changing too many amputees.

Pete Zelinski

Brent and Zac now have this business and they are 3D printing custom prosthetics custom helmet like this one. But it's so new. They've got the facility, they've got the company, they've got the machine, they've invested in all this. Does it make sense? Is there enough work to fill the capacity that they have?

Stephanie Hendrixson

So really interesting question. So looking at this helmet, this is a fairly large 3D printed part. If you think about something like a socket for a leg prosthetic, that's going to be even larger, even taller. And if you have a build, that is just a couple of those big things, you're going to run your printer for a pretty long time and not to get that many parts out of it. It might not make economic sense. But Additive America takes a different approach.

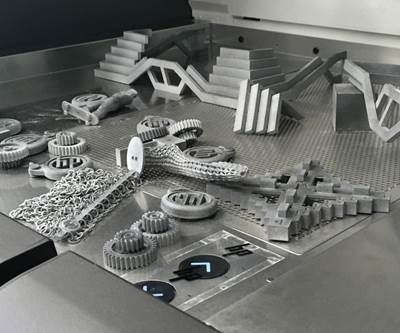

One of the greatest advantages for us is the fact that we're mixing all types of parts together into one build. And that's what we really think helps us to reach an economical figure that's palatable for the current O&P market so that we can get them in and get their feet wet without it costing them much more money or any more money in some cases. But then we're also able to build share kind of as we call it. We take industry parts from automotive, aerospace, consumer goods, short run, production, bridge production, all of those things you're seeing in additive manufacturing, we're also very active in those industries as well. And so we're taking those parts and using them as filler parts essentially to go around some of the larger prostheses or the sockets that go in the build.

Pete Zelinski

Okay, I get it. So a leg prosthetic, or maybe even Sarah's helmet, while it was being built there was all this other stuff around it in the build volume, like tools or prototypes or short run production for customers that had nothing to do with prosthetics.

Stephanie Hendrixson

Yeah. So if you have to plan your build around a couple of large-ish parts, the printer is going to run for the same amount of time if you have three or four parts in versus if you have 100 parts. So you might as well make the most of it, pack as many things as you can into the build and spread that cost across the entire batch.

Pete Zelinski

Okay, last question. You ready? So this helmet is blue. Sarah's helmet that we've seen, it's like blue and purple and silver. So what's going on with the color?

Stephanie Hendrixson

Yeah, let's talk about that. So what we have here is actually sort of a color copy. This was made in a slightly different printer, the jet fusion color. So the design on this one we have in the studio is actually printed right into the surface. In Sarah's case, hers is all those different colors because it is a custom paint job. Her kids are big fans of Guardians of the Galaxy, they call her cochlear implant her robot ear, so she just decided to embrace that and painted it to look like Nebula from the Guardians of the Galaxy movies.

Pete Zelinski

Alright, I think I got this. Sarah Piersanti lost a lot when she regained her hearing. The cochlear implant that gave her hearing back was this sensitive device that had to be protected and potentially took away her ability to engage in jiu-jitsu, something she loves along with her husband, and even had to make her reticent about roughhousing with their kids. Looked for many solutions and nothing quite worked until she happened upon 3D printing, specifically in the form of Eastpoint Prosthetics, and the way that they use Multi Jet Fusion 3D printing to print customized prosthetics. And as it happened, they had some experience with helmets too. Helmets for children for much different conditions, but it applied right to Sarah as well. And after scanning the precise geometric form of her head and what would have to be accommodated with the implant, manipulating the data just a little bit, on the first try they were able to produce the protective helmet that she has worn for a couple years now. Allowed her to find her way back to jiu-jitsu, to fully engage with her family, and painted to match the look of Nebula, the cyborg character from Guardians of the Galaxy in homage to the Marvel Cinematic Universe.

Stephanie Hendrixson

Yeah, so I think that covers it. Thank you so much for watching this episode of The Cool Parts Show. If you'd like to learn more about custom orthotics, Multi Jet Fusion or other things that we talked about in this episode, see the links in the description below. The show is going to go on hiatus for a little bit, but we will be back in the second half of 2021 with brand new episodes, so make sure you're subscribed so you won't miss any of that.

Pete Zelinski

If this is the first time you're seeing the show, man are we glad you're here. So we've done more than 30 episodes now. More than 30 different cool parts solving real problems through 3D printing, different applications, different industries, different products. Check us out watch our episodes TheCoolPartsShow.com

Stephanie Hendrixson

And if you have a cool part you'd like to see featured, email us CoolParts@AdditiveManufacturing.media. Thanks for watching.

Pete Zelinski

Thank you to our sponsor Carpenter Additive. Listen to additive manufacturing podcasts, attend webinars and learn more at CarpenterAdditive.com

Related Content

MedCAD Titanium Facial Reconstruction Plates Now 3D Printed

MedCAD, creators of AccuPlate patient-matched titanium implants, has announced that AccuPlate 3DTi reconstruction plates for the mandible and midface are now 3D printed.

Read MoreIn Armenia, Personalized 3D Printed Shields Improve Fit for Prosthetics

The ongoing conflict in Armenia has left many of its citizens sustaining injuries, especially the loss of limbs. With difficulty in accessing quality health care, many people have poorly fitted prosthetics. The solution lies in 3D modeling and printing customizable prosthetic case covers enabling better healing outcomes and comfort for patients.

Read MoreRead Next

Is Your Dentist a Manufacturer?: The Cool Parts Show #10

Dental devices have always been custom, but 3D printing is disrupting how they are made. We go inside a dental lab in this episode of The Cool Parts Show.

Read MoreHow A Digital Manufacturing Workflow Is Making Orthoses, Prostheses More Accessible

Digitization of the workflow needed to create limb prostheses, orthoses, helmets and more means that these devices will become more readily available. Using 3D scanning and 3D printing, EastPoint Prosthetics and Orthotics and Additive America have established a way to produce these devices that both changes lives and makes business sense.

Read MoreAM 101: Multi Jet Fusion (MJF)

From functional prototypes to end-use parts, HP’s Multi Jet Fusion (MJF) is capable of efficient production. Learn about MJF, including its materials, postprocessing requirements, benefits and more, in this 101 post.

Read More

.jpg;width=70;height=70;mode=crop)