Stephanie Hendrixson

| Additive Manufacturing

Should implants be 3D printed on-site at hospitals, or continue to be made by external manufacturers? We asked Daniel Bomze of Lithoz this question in preparation for our episode on the hydroxyapatite implant. His answer might surprise you.

Stephanie Hendrixson

| Additive Manufacturing

A key advantage of the hydroxyapatite material used in the cranial implant in this week’s episode is how it enables and encourages bone cells to grow into it, via the process known as osseointegration. Dr. Christoph Staudigl shares a quick history lesson on how this behavior was first observed.

Stephanie Hendrixson

| Additive Manufacturing

Beni Cukurel describes the auxiliary equipment that supports this 3D printed turbojet engine’s functionality in this exclusive Extra, just for All Access subscribers.

Stephanie Hendrixson

| Additive Manufacturing

One struggle of developing the engine was maintaining a gap between the rotating and stationary components to accommodate a hydrostatic bearing. Future work will involve other types of bearings.

Peter Zelinski

| Additive Manufacturing

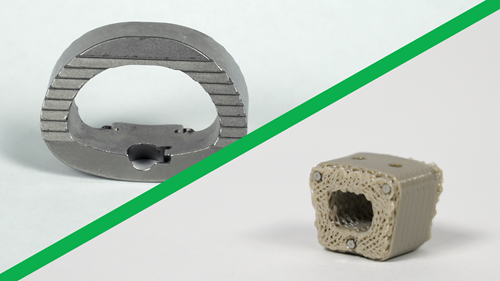

Alpha Precision Group, provider of both processes, discusses considerations that go into making this choice.

Peter Zelinski

| Additive Manufacturing

General Atomics’ Steve Fournier describes how directed energy deposition makes titanium economical for aircraft structural components.

Peter Zelinski

| Additive Manufacturing

NASA's Paul Gradl describes an important application of AM beyond the spacecraft itself: refueling the spacecraft. Directed energy deposition offers the most practical way to produce aluminum tanks to keep fuel supercool.

Peter Zelinski

| Additive Manufacturing

Metafold CEO Elissa Ross describes one of the promises of more effective modeling of geometrically complex 3D printed forms: expanded use of metamaterials. To what extent can material “properties” come from geometry rather than the material itself?

Stephanie Hendrixson

| Additive Manufacturing

Baker Hughes saves optimized production information in its PLM system for reuse later, creating “Golden Master” manufacturing routers. Rohan Buntval, additive manufacturing design engineer, goes into greater detail about how files become golden.

Peter Zelinski

| Additive Manufacturing

As Eaton advances toward production of aircraft ducts now made via 3D printed composite instead of metal, a team member involved with this work considers the machine features that will make them more capable for this role.

Stephanie Hendrixson

| Additive Manufacturing

The top frame isn’t the only 3D printed part used in IndyCar racing. Teams create their own printed parts, and there are other standard components made this way as well. Tino Belli and Dominic Coffey describe several other racing applications, particularly in polymer, in this All Access Extra.

Peter Zelinski

| Additive Manufacturing

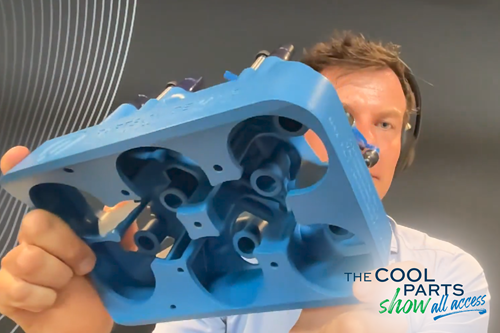

Parts on Demand CEO Neil van Es shows examples of 3D printed food automation hardware.

Peter Zelinski

| Additive Manufacturing

Günter Kappler, designer of the metal bellows in episode 64, describes the extent of the testing that has gone into validating the performance of these 3D printed parts.

Stephanie Hendrixson

| Additive Manufacturing

Todd Reith explains the workflow for creating Curiteva’s 3D printed spine implants from PEEK.

Stephanie Hendrixson

| Additive Manufacturing

Curiteva produces cervical spine implants using PEEK, but today most spine implants are made of metal — specifically, titanium. There are very good reasons to choose titanium, as Erik Erbe describes in this interview clip. But, PEEK may have the edge in terms of stiffness, osseointegration and another important factor we learned about.

Peter Zelinski

| Additive Manufacturing

Lattice structures are great, but they have to end somewhere. When designing head padding made from lattices, how do you design the surfaces where the pads adhere to the helmet? Marek Moffet, chief technical officer for General Lattice, talks about that here.